Fluoride sintered compact for neutron moderator, and method for producing said fluoride sintered compact

A manufacturing method and sintered body technology, applied in the direction of magnesium fluoride, moderator/core structure, magnesium halide, etc., can solve the problems of weak mechanical strength and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

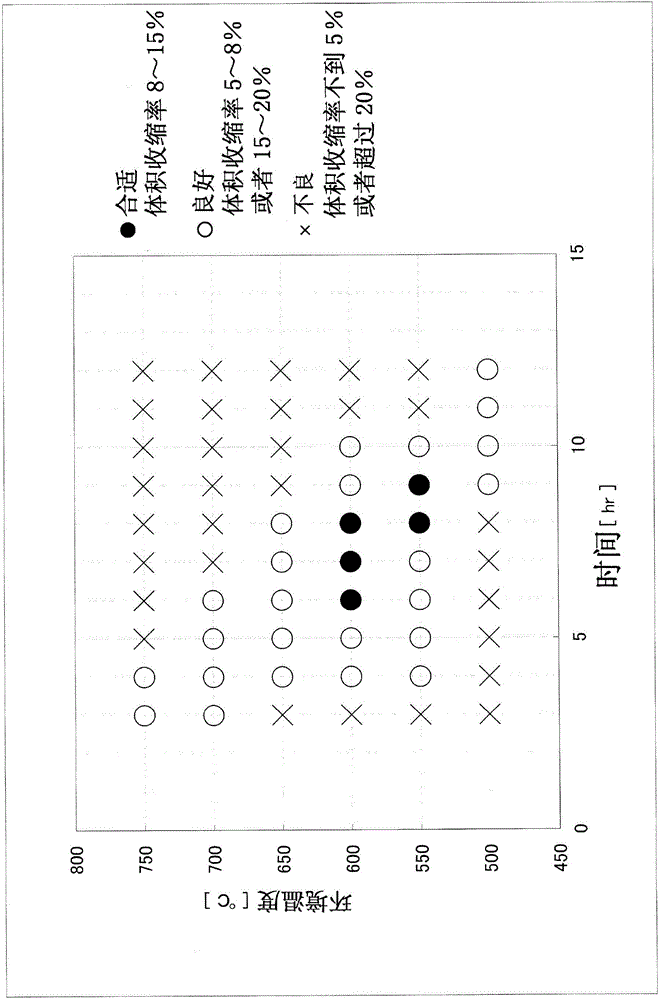

[0177] High-purity MgF2 Raw material (average particle size 20μm, purity 99.9wt% or more) is pulverized into high-purity MgF 2 Powder (average particle size 1.2 μm, purity 99.9 wt%). In this powder with respect to the MgF 2 Powder 100, 0.2wt% hydroxymethyl cellulose (CMC) solution was added as a sintering aid, mixed in a jar mill for 12 hours as a starting material.

[0178] Fill the starting material into the template (the mold size is 220mmx220mmxH150mm), and use a uniaxial press to increase the uniaxial pressure to 10MPa for compression and molding.

[0179] Put the press molded body (dimensions about 220mmx220mmxt85mm) into a thick plastic bag, degas it, and fill the sealed molded body into the forming part of the cold room isometric pressure molding (CIP) machine (internal dimensions: inner diameter 350mmxH120mm) . In the gap between the plastic bag in which the pressurized body was packed and the forming part of the CIP machine, clean water was filled, and the molding...

Embodiment 2

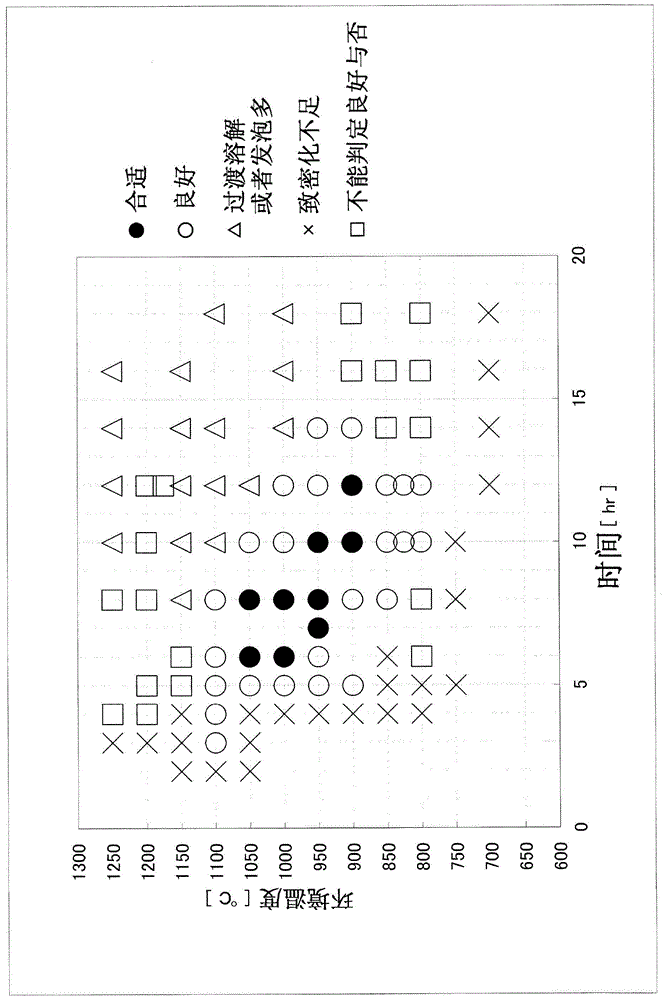

[0187] Using the same starting materials as in Example 1 above, similarly, for a molded body subjected to uniaxial press molding and cold isotropic pressure molding (CIP), temporary sintering was performed at 550° C. for 10 hours in an air environment. , to obtain a temporary sintered body of 208mmx208mmxt73mm. The temporary sintered body was heated from room temperature to 750° C. at a certain speed in a nitrogen atmosphere for 6 hours, and kept at the same temperature for 9 hours. After that, heat up to 920°C at a certain speed for 2 hours, keep the same temperature for 2 hours, then cool naturally to the set take-out temperature of 100°C, and then take it out. The approximate size of the sintered body is 195mmx195mmxt64mm, and the bulk density is 2.90g / cm 3 (relative density 92.1%), the sintered state is good.

[0188] As shown in Table 2, the deceleration performance of neutron rays and the evaluation results of various characteristics were all good.

Embodiment 3

[0190] Using the same starting materials as in Example 1 above, similarly for the molded body that has been subjected to uniaxial press molding and cold isotropic pressure molding (CIP), it is temporarily subjected to 600°C for 8 hours in an air environment. Sintering to obtain a temporary sintered body of 206.5mmx207mmxt71mm. The temporary sintered body was heated from room temperature to 840° C. at a certain speed in a nitrogen atmosphere for 6 hours, and kept at the same temperature for 12 hours. After that, the temperature was raised to 1080° C. at a certain speed for 2 hours, and kept at the same temperature for 1 hour. Then, it was naturally cooled to the set take-out temperature of 100° C., and then taken out. The approximate size of the sintered body is 192mmx192mmxt61mm, and the bulk density is 3.00g / cm 3 (relative density 95.2%), the sintered state is good.

[0191] As shown in Table 2, the deceleration performance of neutron rays and the evaluation results of vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loose density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com