Permanent-magnet synchronous motor

A permanent magnet synchronous motor and magnetic slot technology, which can be applied to motors, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc. The effect of speed regulation range and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

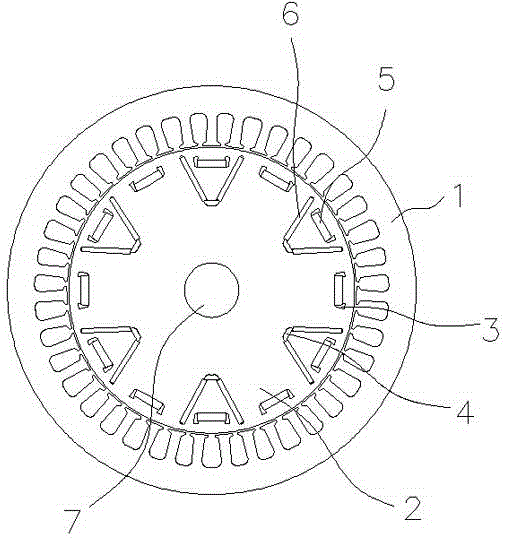

[0026] A permanent magnet synchronous motor, such as figure 1 As shown, it includes the rotor 2 and the stator 1 arranged in the rotor 2. The rotor 2 includes a rotor core as a support. A number of magnetic grooves are engraved on the rotor core. The magnetic steel groups are embedded in the magnetic grooves, and the magnetic grooves are evenly arranged. On the circumference of the cross-section of the rotor core, the magnetic slots include a first magnetic slot 4 and a second magnetic slot 3, the second magnetic slot 3 is close to the circumferential edge of the rotor core cross-section, and the number of the first magnetic slots 4 is the second Half of the number of magnetic slots 3 , the first magnetic slots 4 and the second magnetic slots 3 correspond alternately and are arranged between the corresponding second magnetic slots 3 and the rotating shaft 7 of the rotor core.

[0027] The second magnetic slot 3 is provided with an outer magnetic steel group 5. The outer magnet...

Embodiment 2

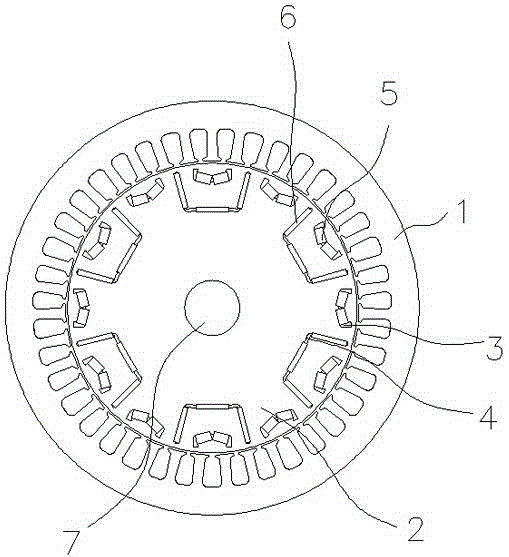

[0032] The difference from Embodiment 1 is that, as figure 2As shown, the outer magnetic steel group 5 includes a "V"-shaped outer magnet whose cross-section is open outward, and the included angle of the outer magnet is an obtuse angle.

[0033] The cross-section of the first magnetic slot 4 is a "U" shape with the opening pointing to the circumference of the cross-section of the rotor core. The inner magnetic steel group 6 includes 3 inner magnets, which are respectively arranged on the two sides and one bottom of the "U" shape. side.

Embodiment 3

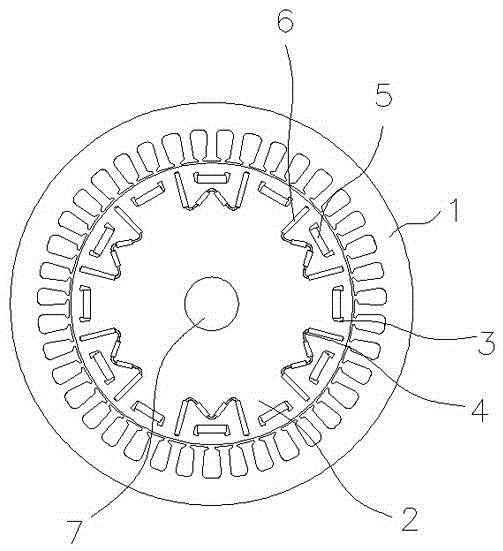

[0035] The difference from Embodiment 1 is that, as image 3 As shown, the cross-section of the first magnetic slot 4 is a "W" shape with the opening pointing to the circumference of the cross-section of the rotor core. The inner magnetic steel group 6 includes four rectangular inner magnets, which are respectively arranged on the "W" "The 4 sides of font.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com