Heating expanded-diameter ice and snow-preventing moderate-intensity aluminum alloy overhead cable

A medium-strength aluminum alloy and overhead cable technology, applied in the direction of power cables, insulated cables, metal/alloy conductors, etc., can solve the problems of increased creep performance, shortened service life, low tensile strength, etc., to reduce gaps , increase the compactness and flatness, the effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

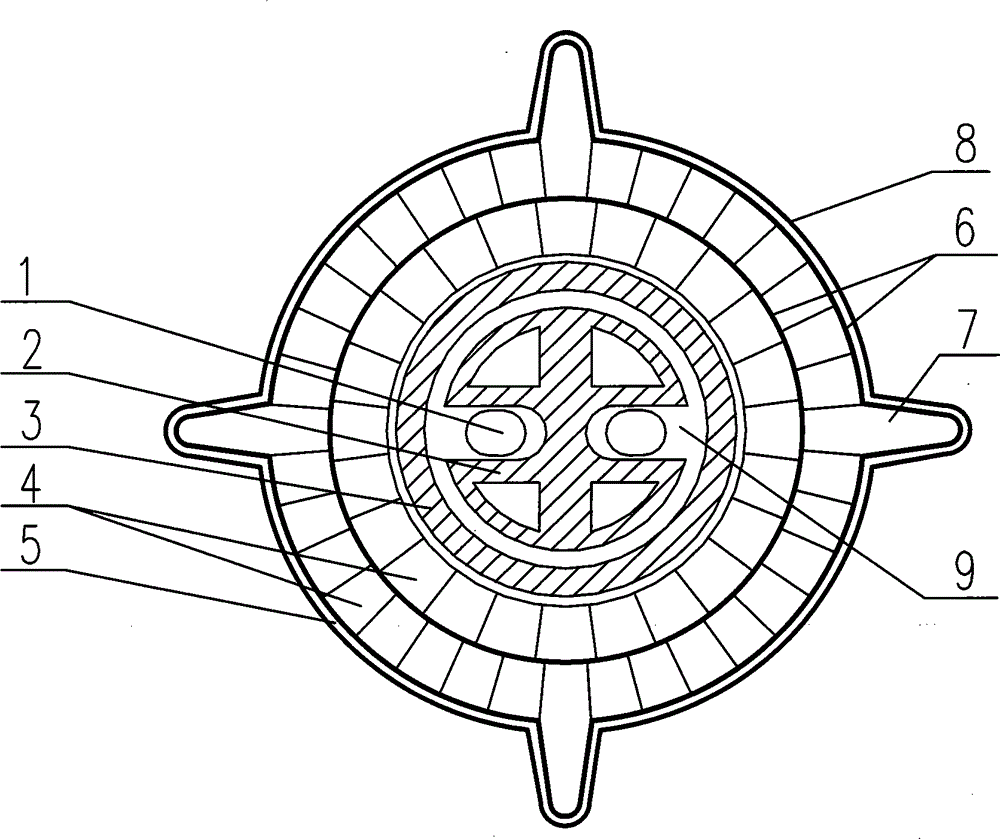

[0012] Example 1. Such as figure 1 As shown, it includes several aluminum alloy monofilament conductors 4, aluminum alloy flexible tubes 3 and insulating layer 5. The cross-sectional shape of the aluminum alloy monofilament conductors 4 is trapezoidal, and the shape of the aluminum alloy flexible tubes 3 is wrinkled. A low Curie point alloy layer 6 is plated on the surface of each aluminum alloy monofilament conductor 4 . The aluminum alloy monofilament conductor 4 is divided into two layers from the inside to the outside and is concentrically stranded on the outer layer of the aluminum alloy soft air tube 3. On the outermost layer of the aluminum alloy monofilament conductor 4, there are four mutually symmetrical finger-shaped The number of protrusions 7 and finger-shaped protrusions 7 may also be one, two, three or more than three as required. The insulating layer 5 is tightly wrapped on the outer layer of the aluminum alloy monofilament conductor 4; the surface of the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com