Method for coating photoresist film and coating equipment using method

A kind of coating equipment and coating technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of reduced production efficiency, uneven thickness of photoresist film, time-consuming and labor-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will now be referred in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

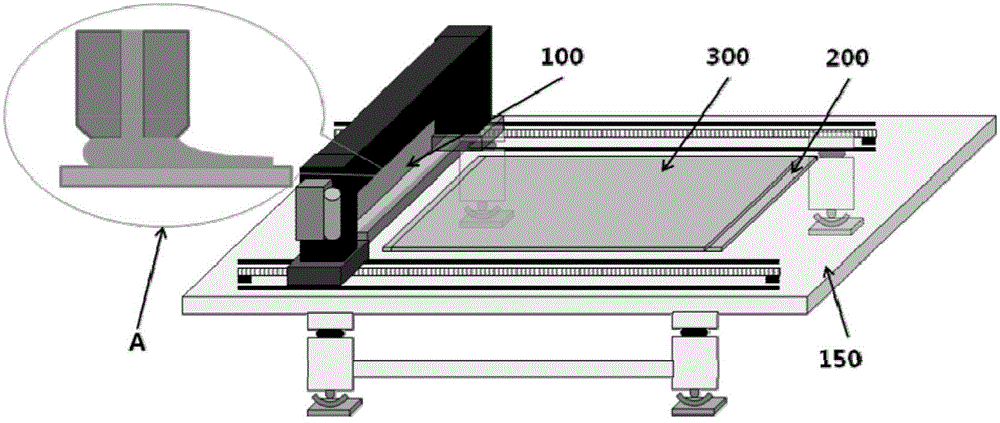

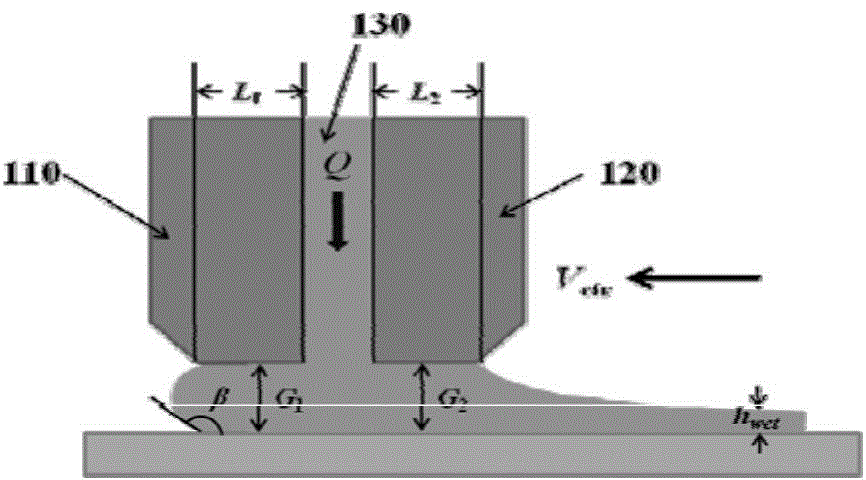

[0033] figure 1 It is a schematic diagram of coating photoresist with a slot-type extrusion coating equipment; figure 2 yes figure 1 The enlarged view of part A in , which also shows the elastohydrodynamic model of the photoresist film thickness according to the embodiment of the present invention (the elastohydrodynamic model of the photoresist film thickness will be described later).

[0034] Such as figure 1 with figure 2 As shown, the slot type extrusion coating apparatus includes a coating platform 150, a coating die 100, a pressure pump (not shown) for supplying photoresist to the coating die 100, and a control for controlling the coating operation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com