A reverse smelting smelting method, nozzle and metallurgical equipment

A reverse, nozzle technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problem of large differences in physical specifications, specific gravity, and chemical composition properties, concentrate particles cannot be oxidized, and swirl intensity is difficult to control, etc. problem, to achieve the effect of large production capacity, complete response, and promotion of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

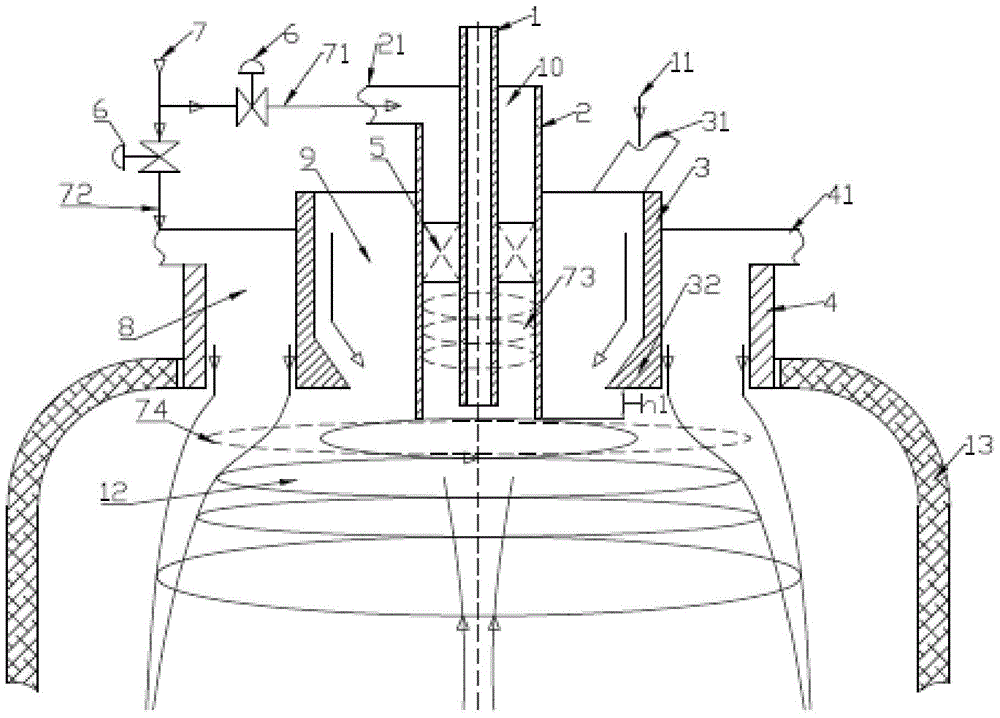

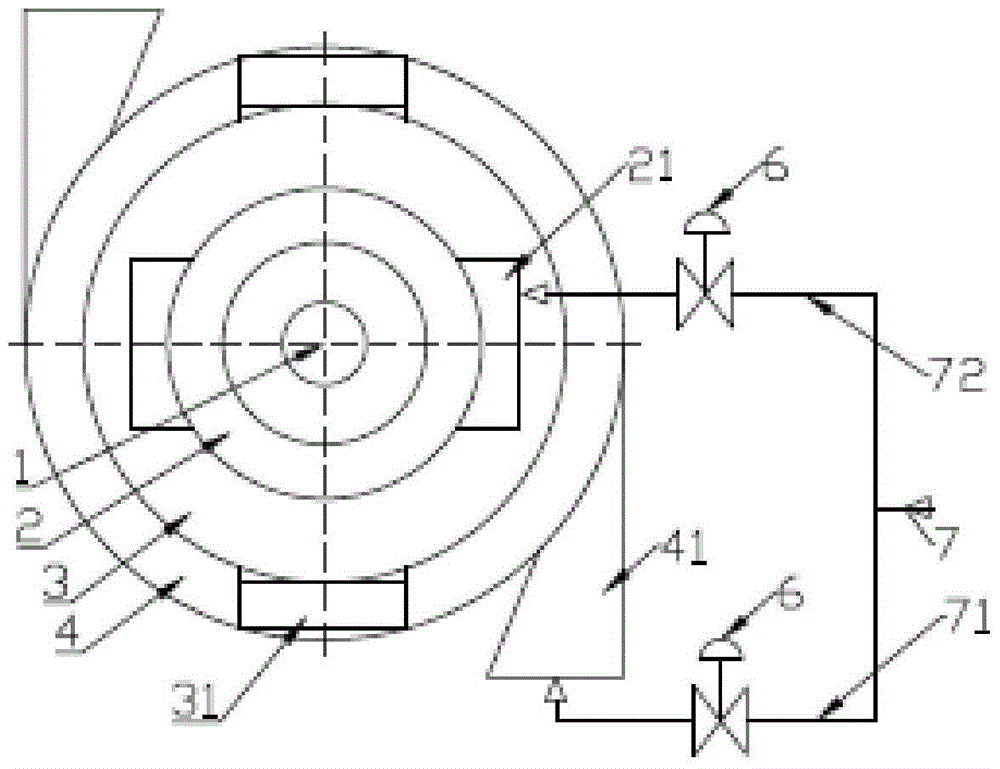

[0035] The invention discloses a new reverse rotary flotation smelting method, in order to improve the utilization rate of oxygen, so that the material reacts completely with oxygen; it overcomes the flashing phenomenon of the swirling flow and the reflux phenomenon of a large amount of high-temperature flue gas in the outer ring, and the required The reaction space is small, there is no reaction dead zone, and the erosion of the refractory material of the furnace body is small. The invention provides a reverse rotation buoyancy smelting nozzle for realizing the above method, and a metallurgical equipment using the above nozzle.

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com