Solid fuel gasification method and system based on chemical working medium cycle

A solid fuel and working medium circulation technology, applied in fuel supply, petroleum industry, combustion equipment, etc., can solve the problems of effective energy loss and other problems, achieve the effect of increasing concentration, significantly reducing carbon dioxide emissions, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

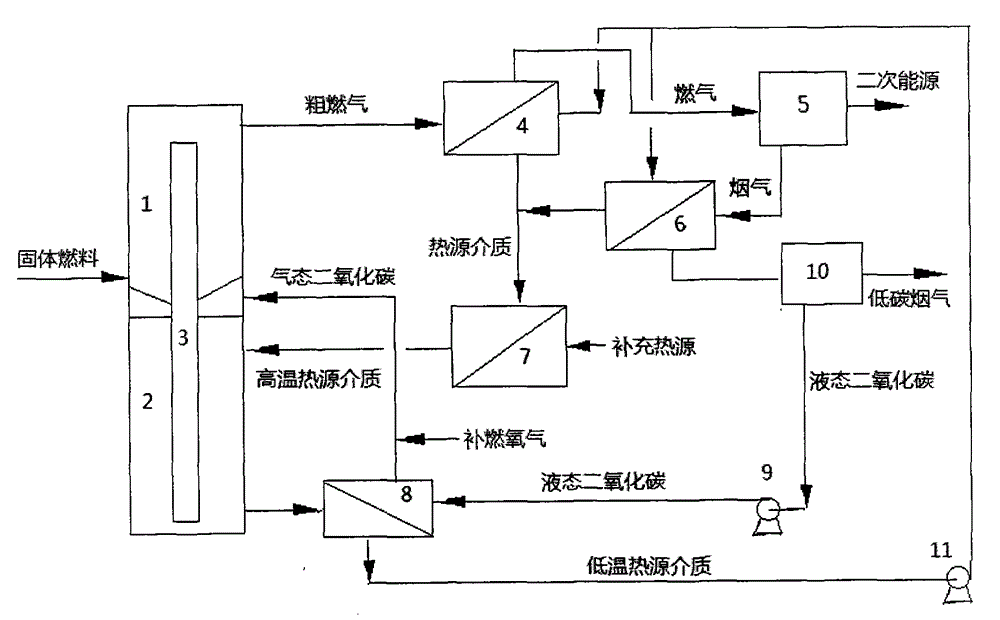

[0013] Taking the carbon dioxide working medium as an example, the invention will be further described in conjunction with the accompanying drawings:

[0014] A solid fuel gasification system based on chemical working medium cycle, see figure 1 , the system includes a gasification reactor 1, a heat pipe absorbing section 2, a heat pipe 3, a gas-heat source medium heat exchanger 4, a gas combustion application device 5, a flue gas-heat source medium heat exchanger 6, and a heat source medium temperature riser 7 , a liquid working medium vaporizer 8, a liquid working medium pump 9, a carbon dioxide trap 10 and a heat source medium pressure feeder 11; the gasification reactor 1 and the heat pipe heat exchange section 2 are integrated by the middle clapboard, the clapboard A plurality of heat pipes 3 are nested on the upper part; the upper part of the gasification reactor 1 is provided with a crude gas outlet pipe, which is connected with the gas-heat source medium heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com