A co that utilizes lng cold energy and exploits hydrate 2 Capture device and capture method thereof

A hydrate and CO2 technology, applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve the problems of inability to achieve storage, inability to efficiently utilize LNG cold energy, inability to efficiently utilize BOG, etc., to achieve Efficient utilization and the effect of improving exergy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

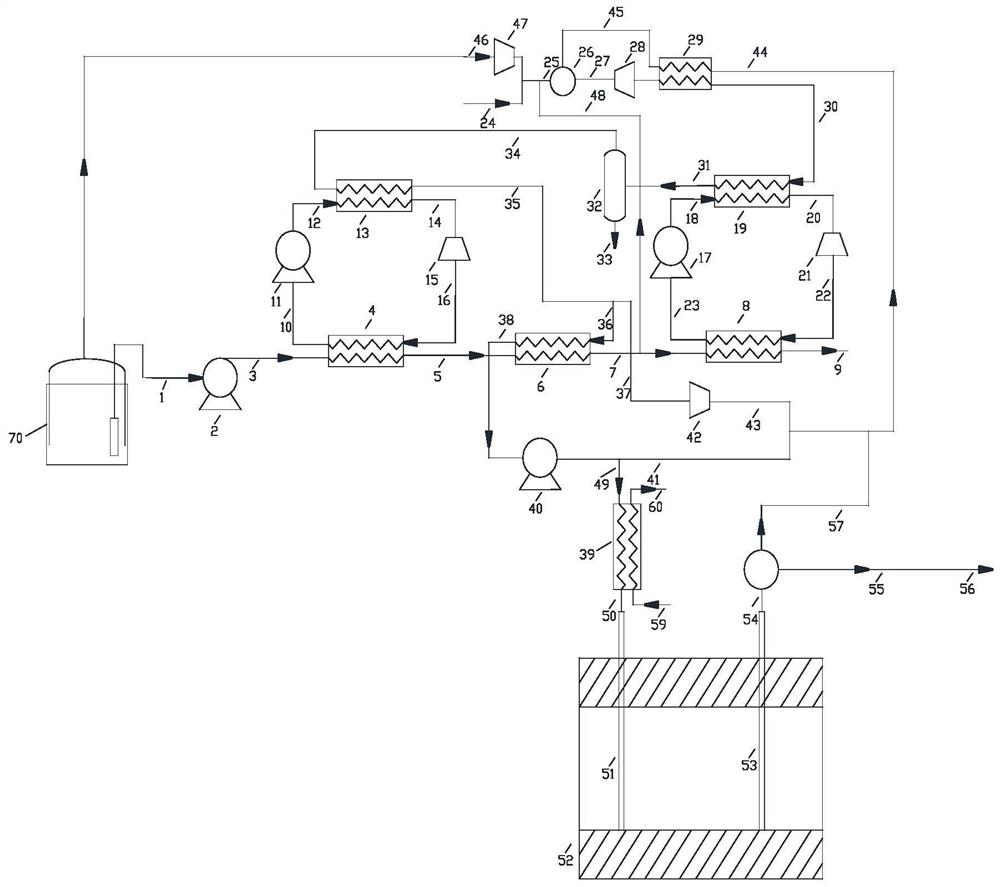

[0035] Such as figure 1 As shown, the figure schematically shows the LNG (liquefied natural gas) cold energy utilization and CO hydrate extraction 2 The capture device includes LNG vaporization system, BOG (boil-off gas) treatment system and CO 2 recycling system.

[0036] In the embodiment of the present application, the LNG vaporization system includes a liquid-phase zone heating subsystem, a gas-liquid two-phase zone heating subsystem, and a gas-phase zone heating subsystem connected in sequence, wherein the output end of the gas-phase zone heating subsystem outputs For natural gas products, the gas-liquid two-phase zone heating subsystem is connected to the BOG processing system, and is used to transport the low-temperature natural gas obtained after the gas-liquid two-phase zone heating subsystem is heated and vaporized to the BOG processing system to balance the BOG processing System material supply.

[0037] The CO 2 The vaporization pressurization output system is ...

Embodiment 2

[0058] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

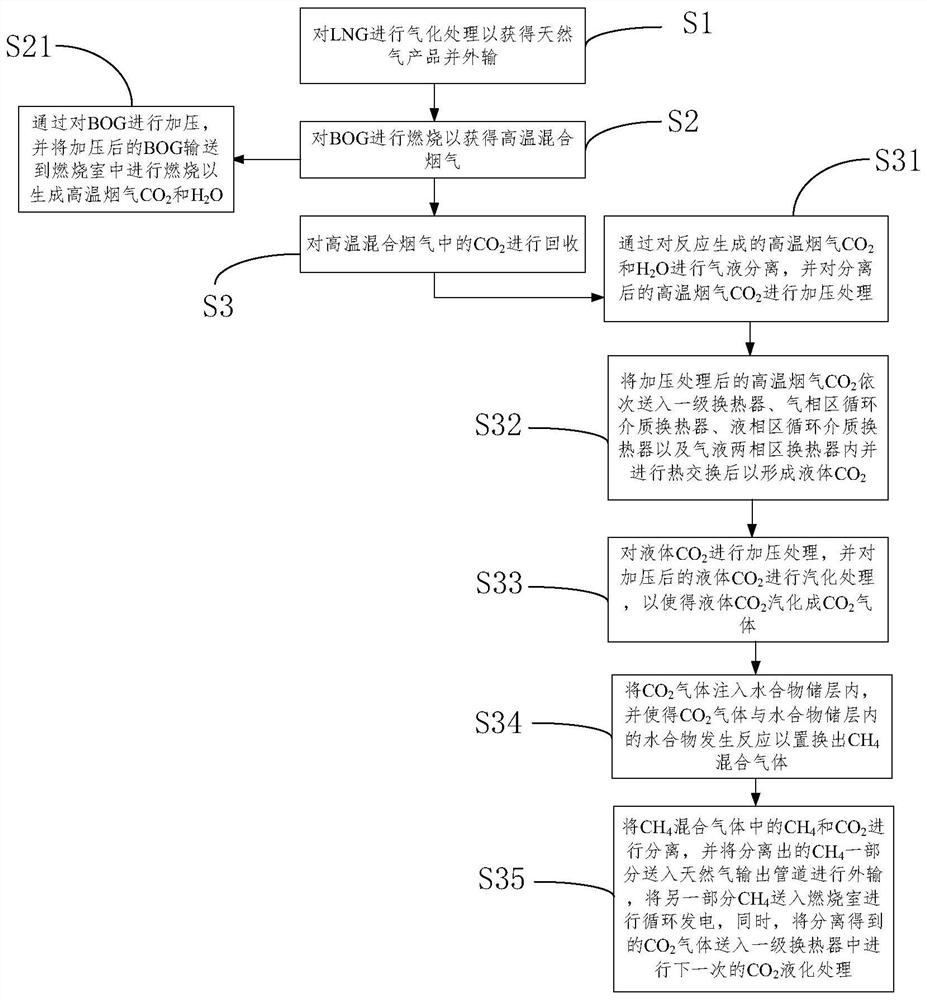

[0059] Such as figure 2 As shown, according to the second aspect of the present application, a CO 2 A capture method comprising the steps of:

[0060] Step S1, performing gasification treatment on LNG to obtain natural gas products and exporting them.

[0061] Step S2, burning the BOG to obtain high-temperature mixed flue gas.

[0062] Step S3, the CO in the high temperature mixed flue gas 2 to recycle.

[0063] In a preferred embodiment, in step S1, the method further includes: making LNG sequentially pass through the liquid-phase zone heating subsystem, the gas-liquid two-phase zone heating subsystem and the gas-phase zone heating subsystem to perform heat exchange to obtain all natural g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com