Gas co-generation technology optimizing system

A technology of combined heat and power supply and process optimization, applied in the directions of preheating, feed water heater, combined combustion mitigation, etc., can solve the problems of low efficiency, unsuitable for regional collective heating and power supply, and achieve mature application technology and improve equipment. Utilization, applicability and popularization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

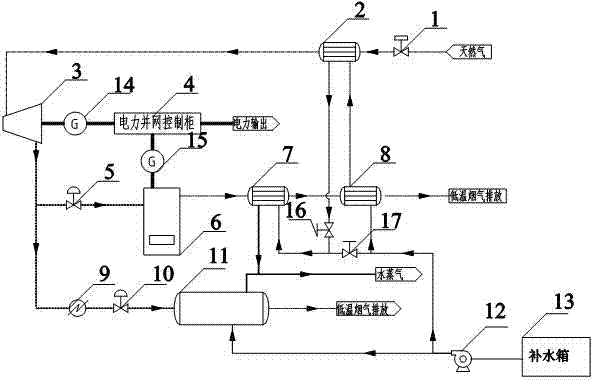

[0029] Such as figure 1 As shown, a gas-fired combined heat and power process optimization system includes a power generation grid-connected system and a heating system;

[0030] The power generation and grid connection system includes first control valves 1, 1 connected to the gas pipeline network in sequence through pipelines # The heat exchanger 2, the expander 3, the gas after the expander 3 is divided into two paths, one path is connected to the first pressure regulating valve 5, the micro-combustion engine 6, and the second generator 15 in sequence, and the other path is connected to the heating equipment in sequence 9. The second pressure regulating valve 10, the flow meter, and the original industrial boiler 11. The first pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com