A temperature-resistant and salt-resistant jelly with low cross-linking agent dosage

A heat-resistant, salt-resistant, and cross-linking agent technology, applied in the field of temperature-resistant and salt-resistant gels and polymer plugging agents, can solve the problems that gels are unfavorable to the sustainable development of oil fields, the plugging effect has no selectivity, and reservoir damage, etc. , to achieve excellent cross-linking performance, low concentration and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

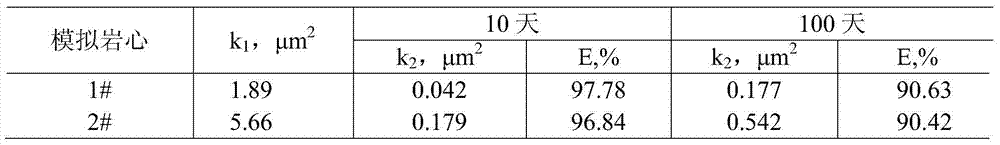

Image

Examples

Embodiment 1

[0017] Add 0.02g of paraformaldehyde, 0.02g of polyethyleneimine, 0.02g of resorcinol, 0.05g of alkoxysilane, and 0.3g of thiourea into 50g of Tahe simulated formation water, stir evenly to make it fully dissolve, and then Mix 50 g of acrylamide / 2-acrylamide-2-methylpropanesulfonic acid copolymer with a mass concentration of 1.2% with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling solution was 9 hours at 130° C., and the strength of the obtained jelly was 0.072 MPa. There was no gel breaking phenomenon after aging at 130° C. for 100 days.

Embodiment 2

[0019] Add 0.03g of paraformaldehyde, 0.02g of polyethyleneimine, 0.02g of resorcinol, 0.05g of alkoxysilane, and 0.3g of thiourea into 50g of Tahe simulated formation water, stir evenly to make it fully dissolve, and then Mix 50 g of acrylamide / 2-acrylamide-2-methylpropanesulfonic acid copolymer with a mass concentration of 1.4% with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling solution was 11 hours at 130° C., and the strength of the obtained jelly was 0.074 MPa. There was no gel breaking phenomenon after aging at 130° C. for 100 days.

Embodiment 3

[0021] Add 0.03g of paraformaldehyde, 0.03g of polyethyleneimine, 0.02g of resorcinol, 0.05g of alkoxysilane, and 0.3g of thiourea into 50g of Tahe simulated formation water, stir well to make it fully dissolve, and then Mix 50 g of acrylamide / 2-acrylamide-2-methylpropanesulfonic acid copolymer with a mass concentration of 1.6% with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling solution was 14 hours at 130° C., and the strength of the obtained jelly was 0.077 MPa. There was no gel breaking phenomenon after aging at 130° C. for 100 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com