High-modulus colored asphalt mixture and preparation method thereof

A technology for asphalt mixture and colored asphalt, applied in the field of asphalt mixture, can solve problems such as road surface damage and occurrence of diseases, and achieve the effects of avoiding diseases, excellent high-temperature shear resistance and anti-rutting performance, and reducing the passing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] S1. Preparation of colored asphalt binder:

[0027] The raw materials are: C5 petroleum resin 16%, C9 petroleum resin 20%, petroleum rubber oil 45%, styrene-butadiene-styrene copolymer 7%, polyethylene PE 8%, polyurethane 4%, All are percentages by mass.

[0028] Heat petroleum-based rubber oil to 175°C, then add C5 petroleum resin, C9 petroleum resin, styrene-butadiene-styrene copolymer, polyethylene PE and polyurethane to it, and shear and stir for 2 to 4 hours , to prepare colored asphalt binder for use.

[0029] S2, preparation of high modulus agent:

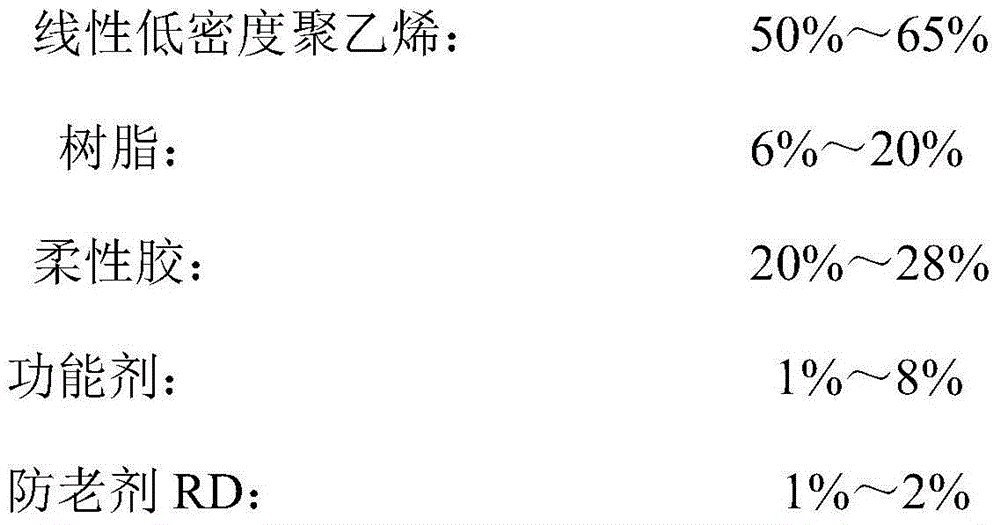

[0030] The raw materials are: 53% of linear low-density polyethylene, 18% of resin, 24% of flexible glue, 3% of functional agent, and 2% of anti-aging agent RD, all of which are in mass percentage. These raw materials are fused, added to the screw extruder, melted and extruded at a cylinder temperature of 180-230°C, a main engine speed of 45-60r / min, and a feeding rate of 45-60r / min, pelletized, dried, and Air-dri...

Embodiment 2

[0040] S1. Preparation of colored asphalt binder:

[0041] The raw materials are: C5 petroleum resin 10%, C9 petroleum resin 25%, petroleum rubber oil 35%, styrene-butadiene-styrene copolymer 15%, polyethylene PE 12%, polyurethane 3%, All are percentages by mass.

[0042] Heat petroleum-based rubber oil to 175°C, then add C5 petroleum resin, C9 petroleum resin, styrene-butadiene-styrene copolymer, polyethylene PE and polyurethane to it, and shear and stir for 2 to 4 hours , to prepare colored asphalt binder for use.

[0043] S2, preparation of high modulus agent:

[0044] The raw materials are: 50% of linear low-density polyethylene, 12% of resin, 28% of flexible glue, 8% of functional agent, and 2% of anti-aging agent RD, all of which are in mass percentage. These raw materials are fused, added to the screw extruder, melted and extruded at a cylinder temperature of 180-230°C, a main engine speed of 45-60r / min, and a feeding rate of 45-60r / min, pelletized, dried, and Air-d...

Embodiment 3

[0049] S1. Preparation of colored asphalt binder:

[0050] The raw materials are: C5 petroleum resin 13%, C9 petroleum resin 18%, petroleum rubber oil 50%, styrene-butadiene-styrene copolymer 7%, polyethylene PE 8%, polyurethane 4%, All are percentages by mass.

[0051]Heat petroleum-based rubber oil to 175°C, then add C5 petroleum resin, C9 petroleum resin, styrene-butadiene-styrene copolymer, polyethylene PE and polyurethane to it, and shear and stir for 2 to 4 hours , to prepare colored asphalt binder for use.

[0052] S2, preparation of high modulus agent:

[0053] The raw materials are: 60% of linear low-density polyethylene, 15% of resin, 20% of flexible glue, 4% of functional agent, and 1% of anti-aging agent RD, all of which are in mass percentage. These raw materials are fused, added to the screw extruder, melted and extruded at a cylinder temperature of 180-230°C, a main engine speed of 45-60r / min, and a feeding rate of 45-60r / min, pelletized, dried, and Air-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com