Bio-electrochemical reactor and application thereof in degrading fluoronitrobenzene wastewater

A technology of bioelectrochemistry and reactor, applied in chemical instruments and methods, electrochemical biocombination treatment, water pollutants, etc., can solve the problems of small cathode and anode area, decrease of biomass and protein content, death, etc., to achieve Effects of reduction of treatment cost, improvement of treatment efficiency, and simplification of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Such as figure 1 As shown, a bioelectrochemical reactor in this embodiment includes a bed body 1 and a cover body (omitted in the figure). 2.

[0052] In this embodiment, the spirally wound electrode 2 is composed of four layers from the outside to the inside, which are the isolation layer 21, the cathode layer 22, the isolation layer 21, and the anode layer 23 in sequence. The anode layer 23 and the cathode layer 22 are connected with a DC stabilizer Piezoelectric source3.

[0053] Among them, the cathode layer 22 is made of hydroxyl-modified carbon felt, and is a folded structure; the anode layer 23 is made of carboxyl-modified carbon felt; the isolation layer 21 is a rigid mesh structure, and is made of insulating polytetrafluoroethylene. material.

[0054] Depend on figure 1 It can be seen that the bed 1 is provided with a water distributor 4 at the periphery of the spirally wound electrode 2 and a water outlet device 6 at the center of the spirally wound electr...

Embodiment 2

[0068] The bioelectrochemical reactor in Example 1 is used to treat fluoronitrobenzene waste water. In this embodiment, the bioelectrochemical reactor has a volume of 1000mL and a liquid filling capacity of 800mL; the selected fluoronitrobenzene A similar substance is p-fluoronitrobenzene.

[0069] Processing includes the following steps:

[0070] (1) Turn on the constant temperature magnetic stirrer, keep the temperature in the bed at 55°C, and keep the stirring intensity at 12kW / m 3 Connect the DC stabilized power supply, apply a voltage of 2V to the spiral wound electrode, and inoculate the high-temperature domesticated sludge into the bed according to the inoculation amount of 4g / L, and hang the film for 7 days;

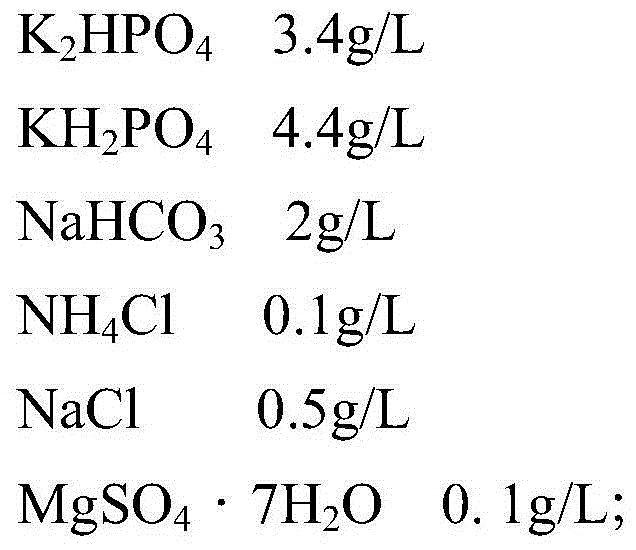

[0071] (2) After the film formation is completed, the electrolyte solution containing p-fluoronitrobenzene (initial concentration is 60mg / L) is sent into the bed body, and the cathode layer and the anode layer in the spiral wound electrode alternately degrade th...

Embodiment 3

[0077]The bioelectrochemical reactor in Example 1 is used to treat fluoronitrobenzene waste water. In this embodiment, the bioelectrochemical reactor has a volume of 1000mL and a liquid filling capacity of 800mL; the selected fluoronitrobenzene A similar substance is p-fluoronitrobenzene.

[0078] Processing includes the following steps:

[0079] (1) Turn on the constant temperature magnetic stirrer, keep the temperature in the bed at 55°C, and keep the stirring intensity at 15kW / m 3 Connect the DC stabilized power supply, apply a voltage of 1.2V to the spiral-wound electrode, inoculate the high-temperature domesticated sludge into the bed according to the inoculum amount of 4g / L, and hang the film for 7 days;

[0080] (2) After the film formation is completed, the electrolyte solution containing p-fluoronitrobenzene (initial concentration is 60mg / L) is sent into the bed body, and the cathode layer and the anode layer in the spiral wound electrode alternately degrade the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com