Pipe end flattening feeding structure

A technology of flat ends and joints at pipe ends, which is applied to metal processing machinery parts, driving devices, metal processing equipment, etc., can solve problems such as unsuitable steel pipes, and achieve high work efficiency, good effect, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

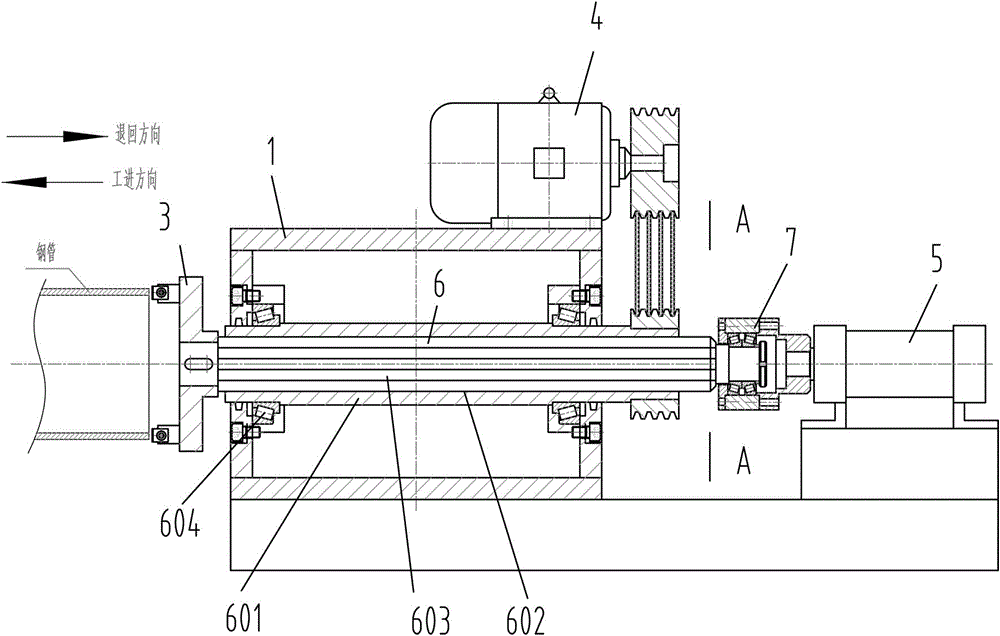

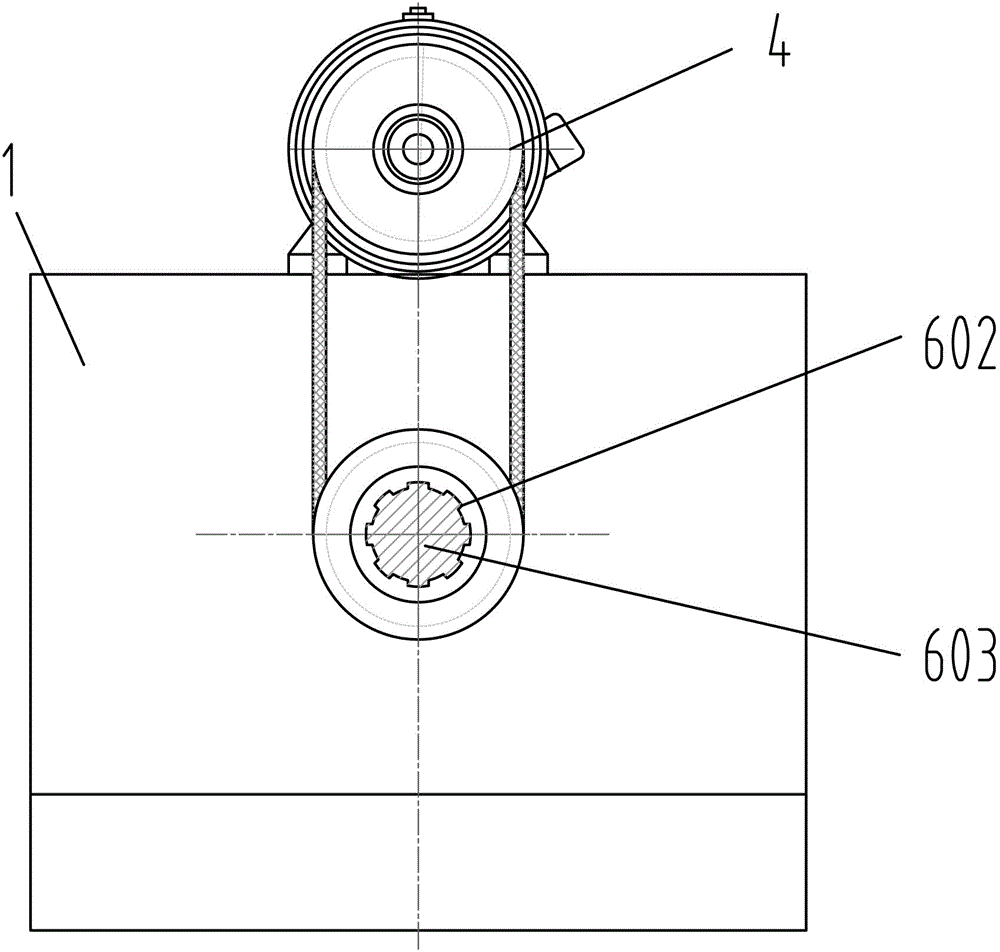

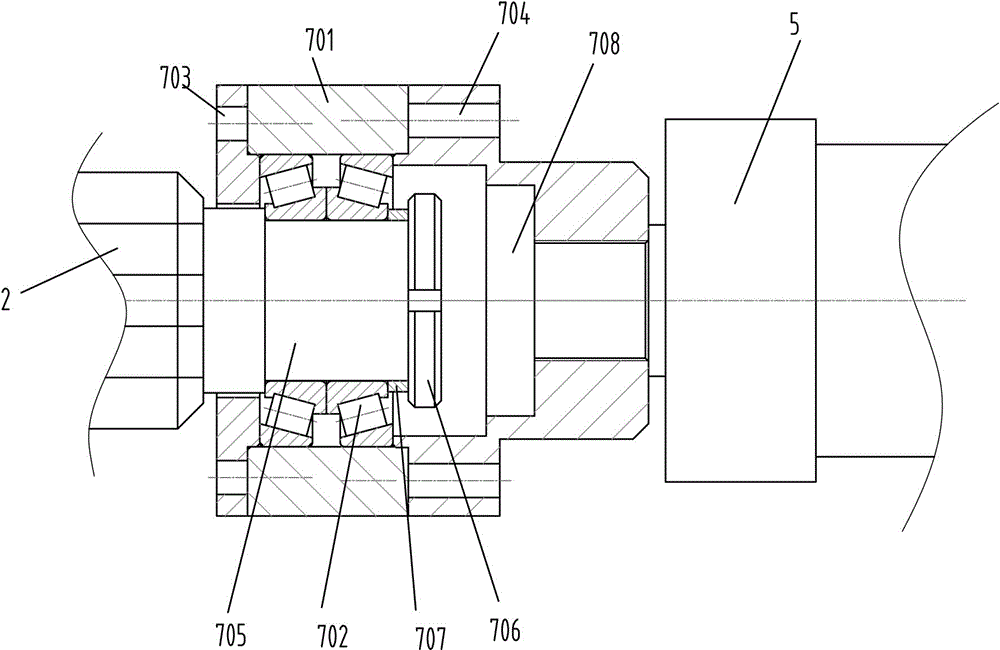

[0021] Example: such as figure 1 , 2 , a pipe end flat head feeding structure shown in 3, including a base 1, a rotating shaft 2 arranged on the base 1, a tool mounting plate 3 fixed on the end of the rotating shaft 2, a The rotary drive part 4 for driving the rotary shaft 2 to rotate, the linear drive part 5 for driving the rotary shaft 2 to move axially, and the rotary drive part 5 arranged between the base 1 and the rotary shaft 2 for The rotary drive part 4 drives the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com