Air floatation rotating reflow soldering device and method

A reflow soldering and rotary technology, applied in electric heating devices, welding equipment, welding/welding/cutting items, etc., can solve the problems of reducing welding efficiency, equipment fatigue damage, low production efficiency, etc., to improve the quality of reflow soldering, improve Service life, simple effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

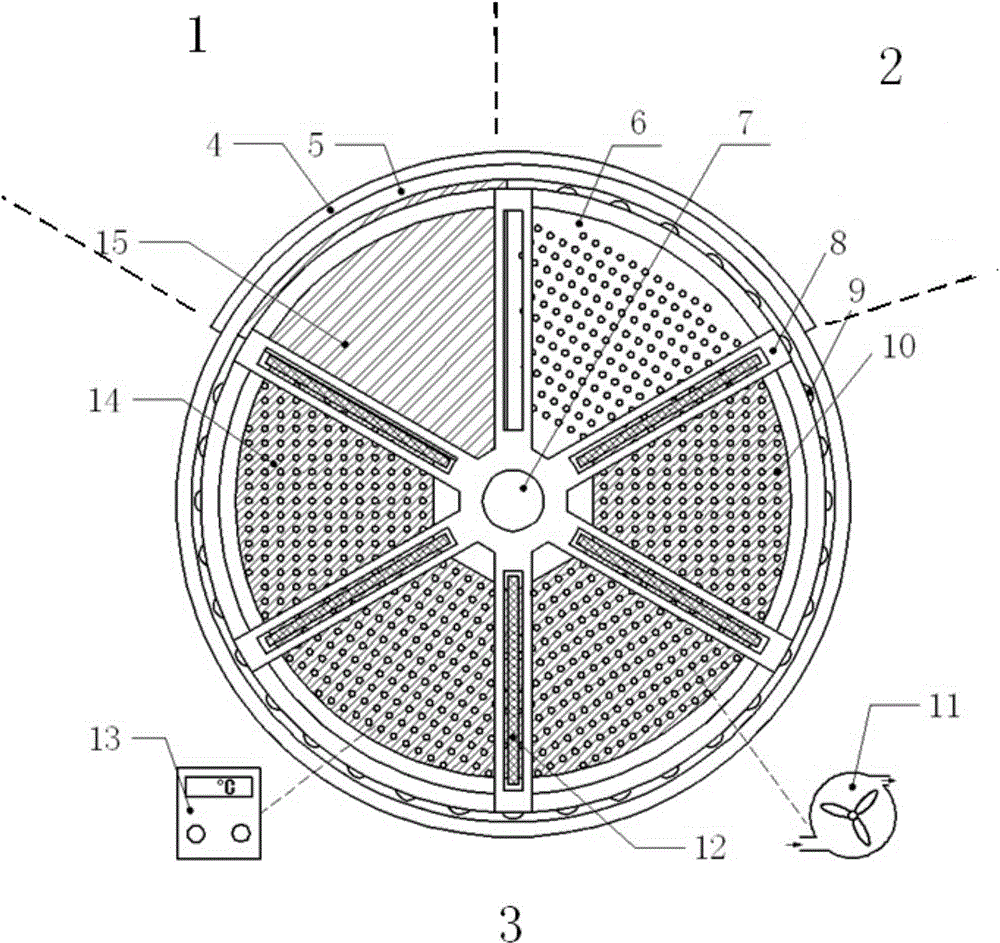

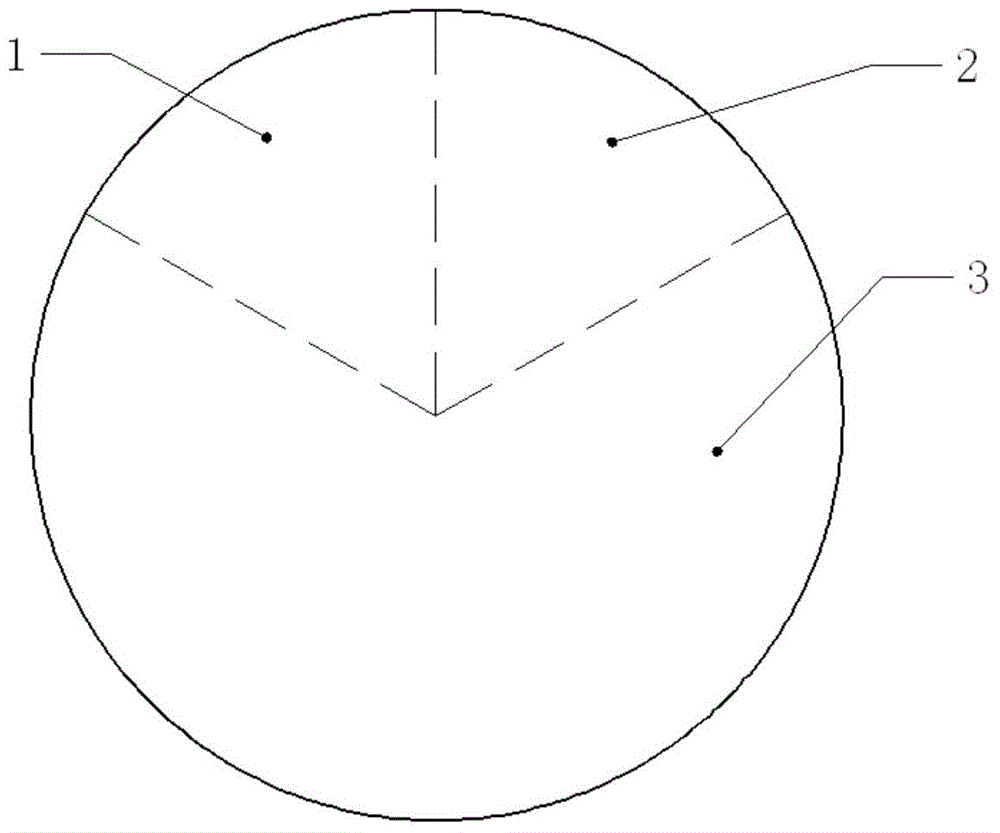

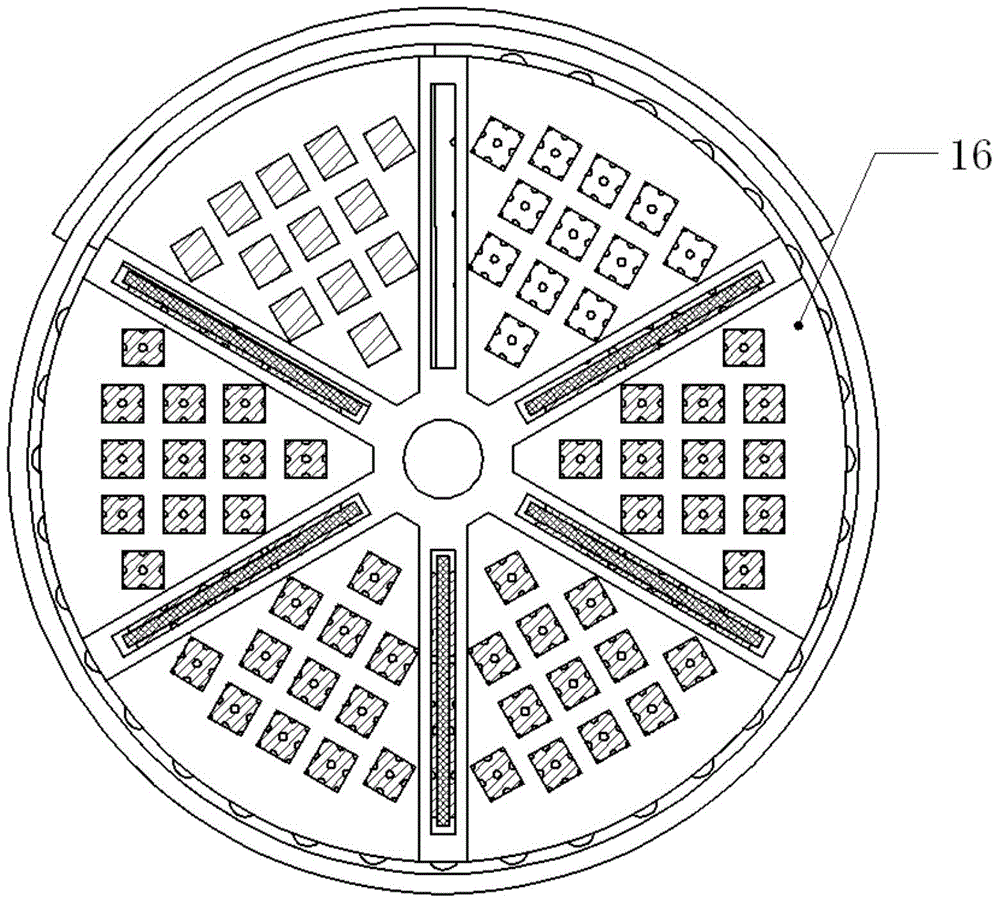

[0040] Such as Figures 1 to 10shown. An air flotation rotary reflow soldering device of the present invention includes a turntable 8, a hot plate 14, a limit plate 16, a furnace body, a furnace door 4, a speed regulating device 7, a temperature controller 13, and a gas regulator 11; The body is composed of a cylinder 6 and a cylinder 5; the top surface of the cylinder 6 is divided into a feeding area 2, a feeding area 1 and a temperature changing area 3; the loading area 2 and the feeding area 1 are close to the furnace door 4, and the furnace door 4 is installed On the cylinder 5, the variable temperature zone 3 is between the loading zone 2 and the unloading zone 1, the unloading zone 1 has a storage tank 15, the storage tank 15 is located on the top surface of the cylinder 6, the loading zone 2 and the variable temperature zone Zone 3 has air holes 10, and the air holes 10 are evenly distributed on the top surface of cylinder 6. Thermal plate 14 is also installed in varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com