High-temperature kiln integrated combustion system for emulsifying and atomizing fuel oil

A combustion system and oil emulsification technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problem of inability to use waste oil such as kerosene, combustion, etc., achieve simple and reasonable structure, high atomization degree, and achieve high temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

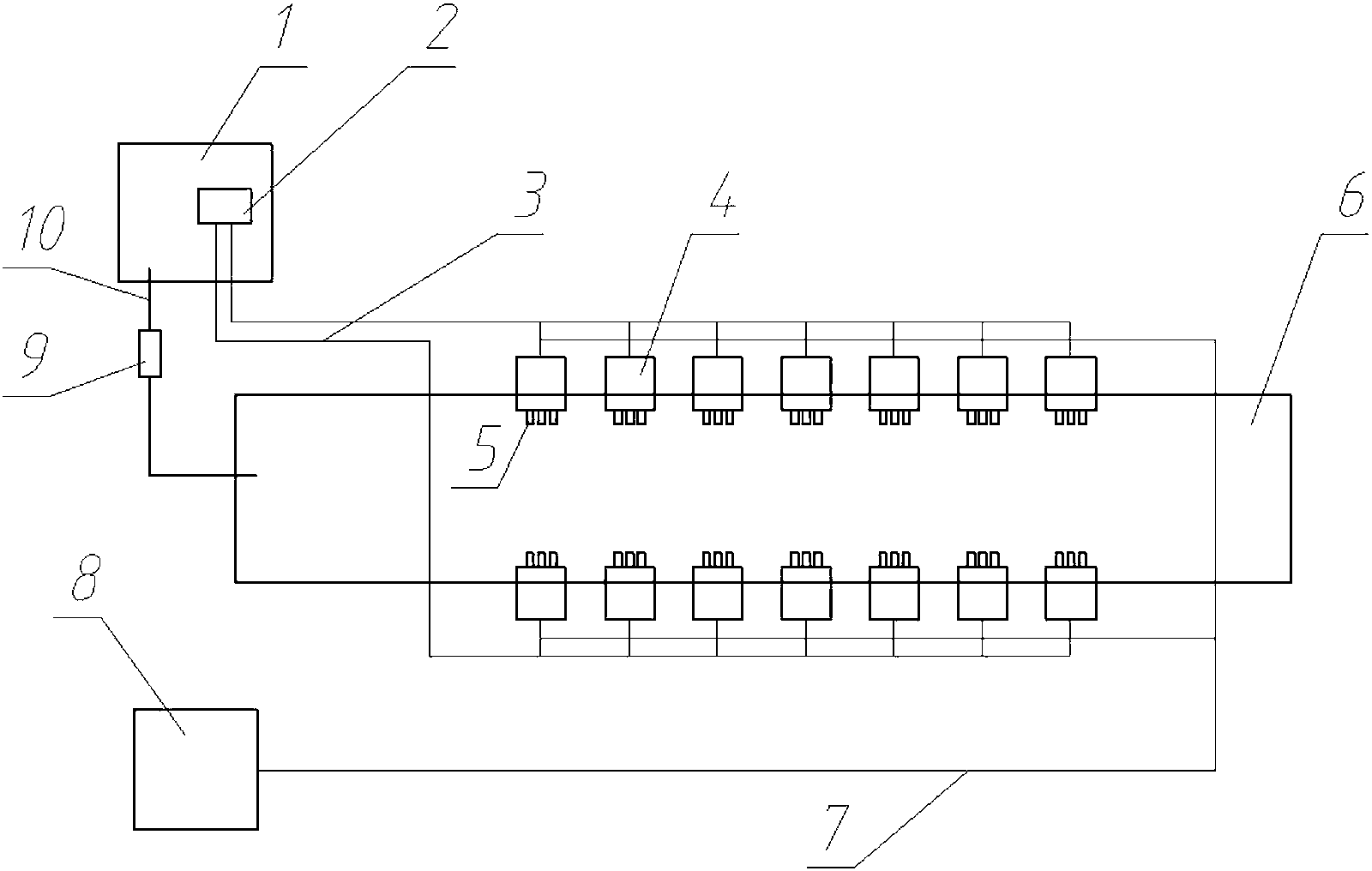

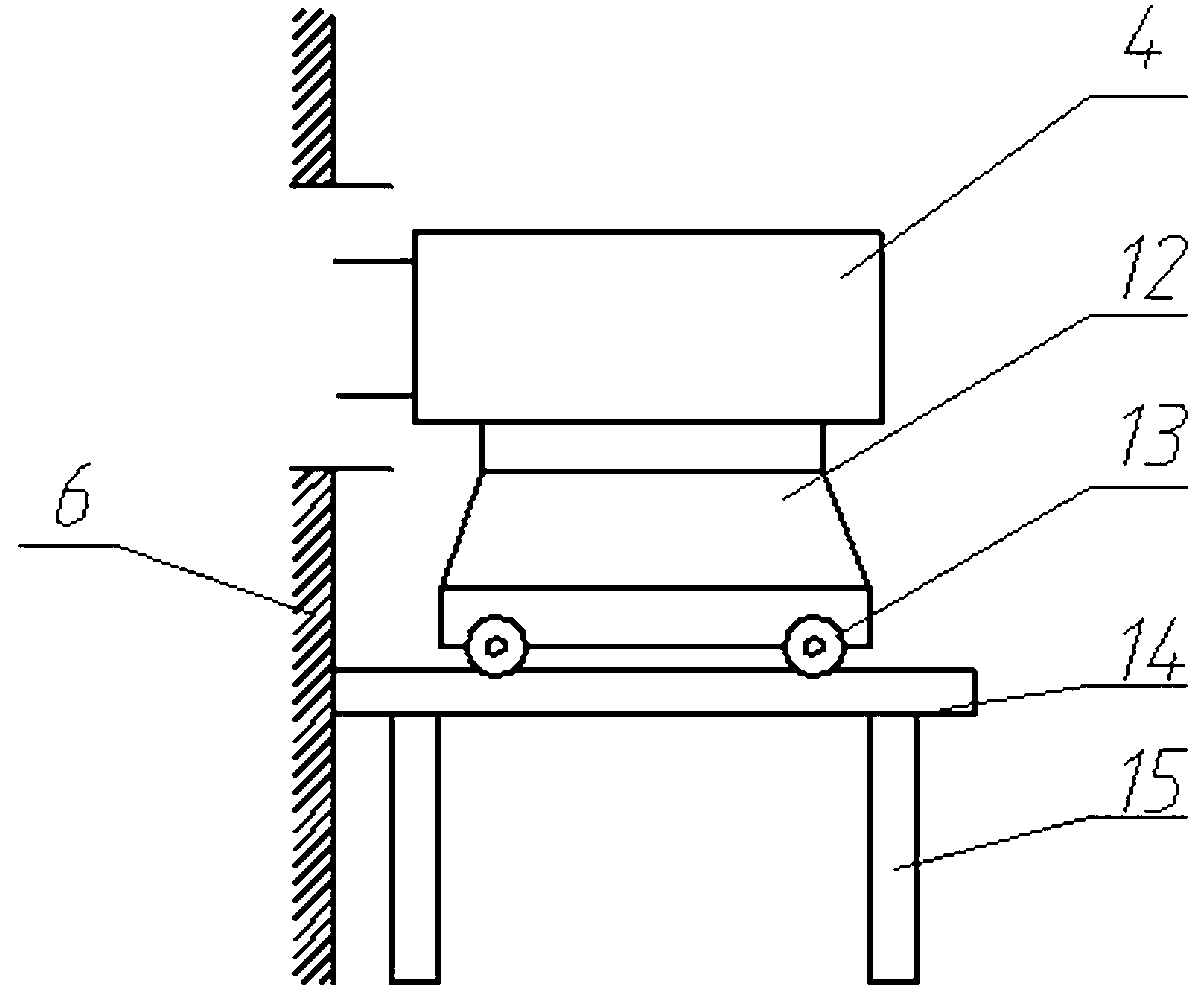

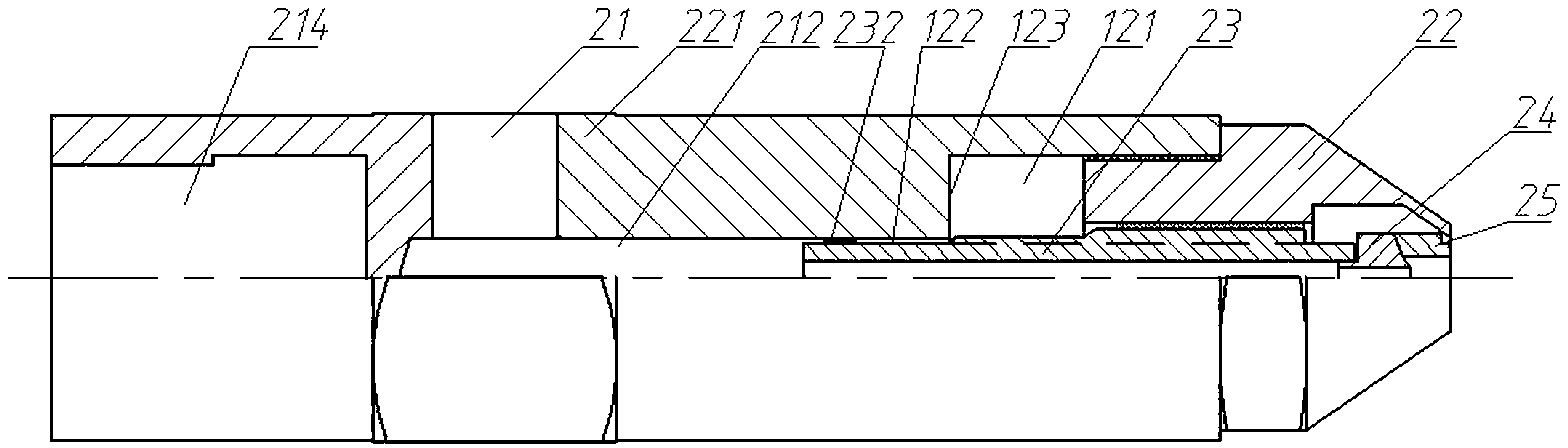

[0014] The integrated combustion system of burning fire oil emulsified and atomized high-temperature kiln includes a number of waste oil burners 4 arranged side by side on the outer wall of the kiln 6. Both are connected to the fuel pipeline 3, the fuel pipeline 3 is connected to the supply pump 2 located on the combustion oil emulsification storage tank 1, the waste oil burner 4 is connected to the air supply pipeline 7, and the air supply pipeline 7 is connected to the air compressor 8. The waste oil burner 4 is specifically supported by a bracket provided outside the kiln 6. The bracket includes a lower fixed frame 15, a track 14 is provided on the fixed frame 15, and a movable frame 12 is arranged above the fixed frame 15. The movable frame 12 There is a pulley 13 stuck on the track 14 below, and a waste heat delivery pipeline 10 is connected between the kiln 6 and the combustion oil emulsification storage tank 1, and a fan 9 is arranged on the waste heat delivery pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com