Chemical oxidation restoration method for organic polluted soil

A chemical oxidation and organic pollution technology, applied in the field of environmental engineering, can solve problems such as pollution, restricted soil permeability, shallow repair depth, etc., and achieve the effects of ensuring uniform mixing, improving oxidation effect, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

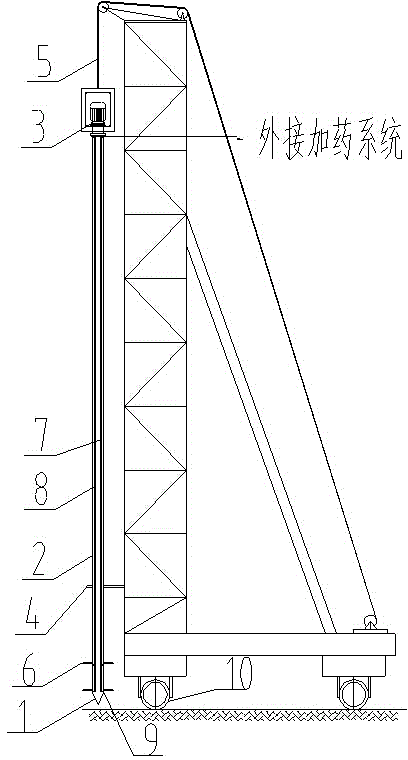

Image

Examples

Embodiment 2

[0036] 830m of the organically polluted soil block of the former Nanjing Chemical Plant 2 , the organic pollutants in the soil are mainly o (p) nitrochlorobenzene, benzene, chlorobenzene, and nitrobenzene, with concentrations of 2430mg / kg, 212mg / kg, 350mg / kg, and 550mg / kg, respectively. Process according to the method of the present invention, the contaminated area is arranged 2500 sites according to the size of each site of 0.6 * 0.46m, when each site is processed, the speed of drilling rod drilling is 20m / h, when going down, Pass 30% sulfuric acid solution to adjust the pH value of the soil to 5; when lifting the drill, the speed is 20m / h, and the catalyst ferrous sulfate with a concentration of 10% and the hydrogen peroxide solution with a concentration of 15% are added through the pipeline switch, The dosage is 500L / h and 650L / h, and the concentration of organic pollutants in the soil is reduced to 16.15mg / kg and the concentration of benzene to 3.5mg / kg after sampling and ...

Embodiment 3

[0038] 750m of organically polluted soil from the former Nanjing Chemical Plant 2, the organic pollutants in the soil are mainly o (p) nitrochlorobenzene, benzene, chlorobenzene, and nitrobenzene, with concentrations of 2530mg / kg, 262mg / kg, 320mg / kg, and 510mg / kg, respectively. Process according to the method of the present invention, the polluted area is arranged 2500 sites according to the size of each site of 0.6 * 0.46m, when each site is processed, the speed of drill pipe drilling is 30m / h, when going down, Pass 30% sulfuric acid solution to adjust the pH value of the soil to 4.5; when lifting the drill, the speed is 30m / h, and the catalyst ferrous sulfate with a concentration of 20% and the hydrogen peroxide solution with a concentration of 25% are added through the pipeline switch, The dosage is 500L / h and 600L / h, and the concentration of organic pollutants in the soil is reduced to 24.15mg / kg and the concentration of benzene is reduced to 13.5mg / kg. , the concentratio...

Embodiment 4

[0040] 2000m of organically polluted soil from the former Nanjing Chemical Plant 2 , the organic pollutants in the soil are mainly o (p) nitrochlorobenzene, benzene, chlorobenzene, and nitrobenzene, with concentrations of 2480mg / kg, 234mg / kg, 340mg / kg, and 410mg / kg, respectively. Process according to the method of the present invention, the polluted area is arranged 2500 sites according to each site size is 0.6 * 0.46m, when each site is processed, the speed of drill pipe drilling is 15m / h, when going down, Add 30% sulfuric acid solution to adjust the pH value of the soil to 4; when the drill is lifted, the speed is 20m / h, and the catalyst ferrous sulfate with a concentration of 10% and the potassium permanganate solution with a concentration of 10% are added through the pipeline switch , the dosage is 500L / h and 600L / h, after the treatment, the sample is taken at intervals of two days. kg, the concentration of chlorobenzene decreased to 6.9 mg / kg, and the concentration of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com