Deoxygenating and desulfurization double-function fine desulfurization agent and preparation method thereof

A fine desulfurization and dual-function technology, which is applied in the field of catalysts and preparations required for the purification of methanol raw material gas produced from coke oven gas and converter gas, and can solve the problem of easy loss of sulfuric acid hydrolysis active components and unstable maintenance of deoxygenation and desulfurization activities , Difficult to maintain activity stability and other issues, to achieve the effect of avoiding sulfation inactivation, ensuring activity stability, and activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

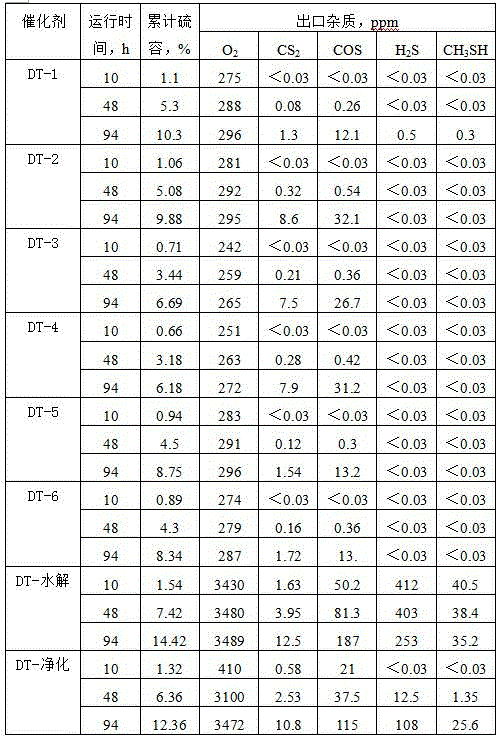

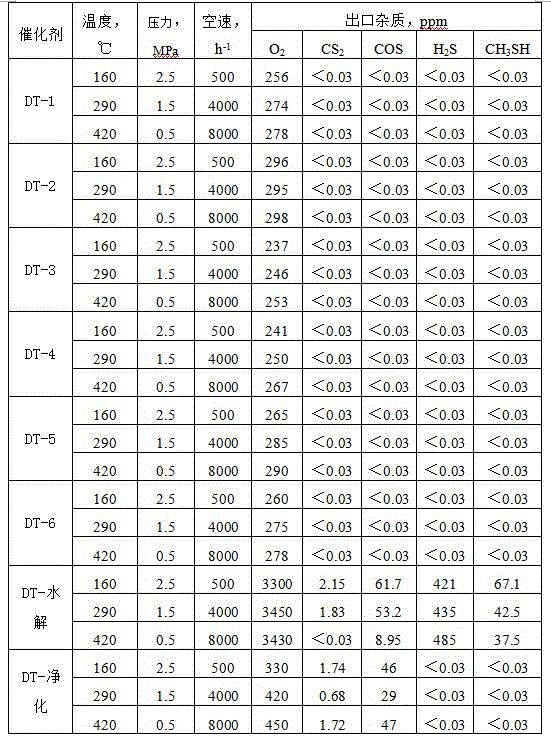

Examples

Embodiment 1

[0025] Dissolve 15g of copper nitrate in 75ml of deionized water to make a solution. Weigh γ-Fe 2 o 3 72.3g of raw powder, 33g of lime, and 4g of scallop powder, mix and grind evenly, then add the prepared copper nitrate solution, stir and roll evenly, then extrude, place for 4h, dry at 110°C for 4h, and then dry at 500°C After 7 hours of calcination, the composite oxide precursor was obtained. Then, weigh 6.1g of ammonium molybdate and 1.1g of citric acid, dissolve them in 62.5ml of deionized water, and place them for 10 hours, soak the composite oxide precursor for 6 hours, place them for 6 hours, bake them at 120°C for 3 hours, and then bake them at 450°C 4h, promptly make described deoxygenation desulfurization bifunctional fine desulfurizer product, wherein Fe 2 o 3 65%, CaO 25%, CuO 5%, MoO 3 5%. The bulk density is 0.85g / cm 3 , specific surface area 110g / m 2 , pore volume 0.28ml / g, named DT-1 catalyst.

Embodiment 2

[0027] Dissolve 36.7g of zinc nitrate in 70ml of deionized water to make a solution. Weigh γ-Fe 2 o 3 44.5g of raw powder, 52.8g of lime, 4g of safflower powder, mix and grind evenly, then add the prepared zinc nitrate solution, stir and roll evenly, then extrude, place for 4h, dry at 150°C for 3h, and then dry at 400°C After calcination at ℃ for 8h, the composite oxide precursor was obtained. Then, weigh 12.2g of ammonium molybdate and 2.2g of citric acid, dissolve them in 57.5ml of deionized water, and place them for 12 hours, soak the composite oxide precursor for 8 hours, place them for 6 hours, bake at 100°C for 5h, and bake at 550°C 2h, promptly make described deoxygenation desulfurization bifunctional refined desulfurizer product, wherein Fe 2 o 3 40% for CaO, 10% for ZnO, 10% for MoO 3 10%, the bulk density is 0.95g / cm 3 , specific surface area 102g / m 2 , pore volume 0.24ml / g, named DT-2 catalyst.

Embodiment 3

[0029]Dissolve 12.7 g of antimony nitrate in 60 ml of deionized water to prepare a solution. Weigh 61g of manganese ore powder, 52.4g of magnesium oxide, and 4g of scallop powder, mix and grind evenly, then add the prepared antimony nitrate solution, stir and roll evenly, then extrude into shape, after standing for 4h, dry at 130°C for 3.5h, The composite oxide precursor was obtained after calcining at 600° C. for 6 h. Then, weigh 6.1g of ammonium metatungstate and 0.4g of citric acid, dissolve them in 50.5ml of deionized water, and place them for 8 hours, soak the composite oxide precursor for 4 hours, place them for 6 hours, bake them at 130°C for 1h, and then dry them at 500°C Roasting at lower temperature for 4 hours to impregnate the composite oxide precursor etc., drying at 120°C, and roasting at 450°C for 4 hours to obtain the deoxidation and desulfurization dual-functional fine desulfurizer product, in which MnO 2 55%, MgO is 36%, Sb 2 o 3 6%, WO 3 5%, the bulk den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com