Preparation method and application of jasmine plant leaf cell extract

A technology for plant leaves and jasmine flowers, which is applied in the field of preparation of jasmine flower leaf cell extracts, can solve the problems of serious loss of polyphenols, low selectivity of extracts, difficult operation and control, etc., achieves product safety, shortens extraction time, The effect of lowering the boiling point of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of samples: pick jasmine leaves, cut them into pieces, use 40 mesh to crush them, and set aside.

[0027] (2) Weigh ethanol 10 times the weight of jasmine plant leaves and mix them with jasmine plant leaves in a flask to form a feed solution. The vacuum degree in the system is 0.6MPa, and the temperature is 55°C and the ultrasonic power is 420W. React for 12min, the mass fraction It is 70% ethanol, and after the whole extraction is completed, the tea polyphenol extract is collected by filtration, which is marked as sample 1.

[0028] (3) Determination of tea polyphenols content: adopt high performance liquid chromatography to carry out the mensuration of tea polyphenols content (, its analysis time is short, easy to operate. Its optimal analysis condition is: methyl alcohol: water: acetic acid=20:60: 0.4 (volume ratio), flow rate is 1.1ml / min, injection volume: 5×10 -3 , the temperature is 25°C, and the wavelength of the ultraviolet detection wave is 2...

Embodiment 2

[0038] (1) Pretreatment of samples: pick jasmine leaves, cut them into pieces, use 60 mesh to crush them, and set aside.

[0039] (2) Take by weighing 15 times of jasmine plant leaf weight ethanol and jasmine plant leaves to mix in a flask to form a feed liquid, connect the equipment, turn on the vacuum pump to make the whole system form a negative pressure, the vacuum degree in the system is 0.4MPa, at a temperature of React at 50°C and ultrasonic power of 420W for 1min, and the mass fraction of ethanol is 70%. After the whole extraction is completed, the tea polyphenol extract is collected by filtration, which is marked as sample 2.

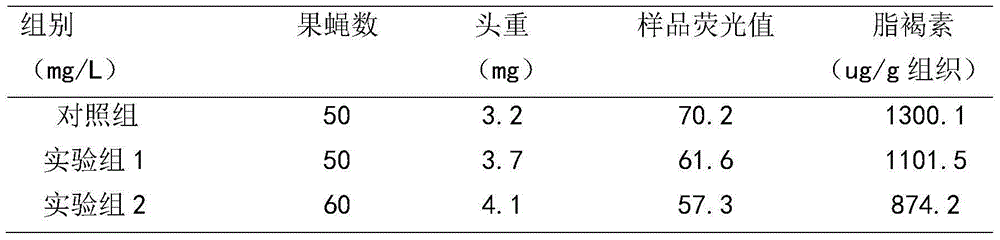

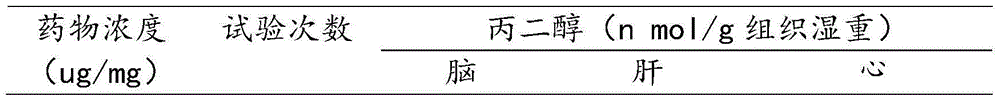

[0040] Determination of the content of propylene glycol, a lipid peroxidation product, on sample 2: Determination of the content of propylene glycol, a lipid peroxidation product, in vitro tissue homogenate of Kunming mice and different concentrations of tea polyphenols;

[0041] Experimental grouping: 270 Kunming mice were divided into 3 group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com