Preparation method of powdered grease of macadimia nut oil

A technology for powdered oil and nut oil, applied in the field of macadamia oil powdered oil and its preparation, can solve the problems of easy oxidation and failure, difficult storage, etc., and achieves good embedding effect, high embedding rate, and improved sticking phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

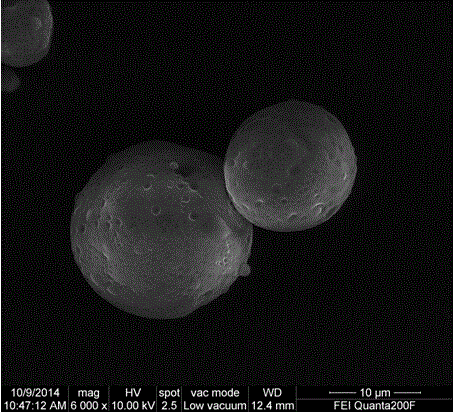

Image

Examples

Embodiment 1

[0018] (1) Take 1200g of pure water according to the weight ratio, heat it to 72°C, add 320g of macadamia nut oil and 12g of mono- and di-glycerides in turn, stir and dissolve, and make A liquid;

[0019] (2) Take 2000g of pure water according to the weight ratio, heat it to 57°C, add 600g of corn glucose syrup, 30g of skimmed milk powder, 8g of sodium stearoyl lactylate and 20g of dipotassium hydrogen phosphate in sequence, stir and dissolve, and make B liquid;

[0020] (3) Take 1200g of pure water according to the weight ratio, heat it to 52°C, add 22g of sodium caseinate, 6g of sodium tripolyphosphate, 3g of sodium hexametaphosphate and 30g of macadamia nut protein in sequence, stir and dissolve, and make liquid C;

[0021] (4) At 57°C and a stirring speed of 1200r / min, pour liquid C into liquid B at a constant flow rate (the time spent is 6 minutes), and after stirring for 6 minutes, add liquid A to the BC mixture at a constant flow rate (the The consumption time is 15min)...

Embodiment 2

[0026] (1) Take 100g of pure water according to the weight ratio, heat it to 70°C, add 30g of macadamia nut oil and 0.8g of mono- and di-glycerides in turn, stir and dissolve, and make A liquid;

[0027] (2) Take 180g of pure water according to the weight ratio, heat it to 55°C, add 58g of corn glucose syrup, 2g of skimmed milk powder, 0.5g of sodium stearoyl lactylate and 1g of dipotassium hydrogen phosphate in sequence, stir and dissolve, and make B liquid;

[0028] (3) Take 80g of pure water according to the weight ratio, heat it to 50°C, add 1.8g of sodium caseinate, 0.3g of sodium tripolyphosphate, 0.1g of sodium hexametaphosphate and 1g of macadamia nut protein in sequence, stir and dissolve, and make liquid C ;

[0029] (4) At 55°C and a stirring speed of 1200r / min, pour solution C into solution B at a constant flow rate (the time spent is 6 minutes), and after stirring for 5 minutes, add solution A at a constant rate to BC mixture (the It takes 15 minutes), after mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com