Disinfectant with low corrosiveness

A disinfectant and corrosive technology, applied in the directions of disinfectants, biocides, bactericides, etc., can solve problems such as the inability to ensure the quality of surgical instruments, the toxicity of glutaraldehyde disinfectants, and the impact on the service life of surgical instruments. Low toxicity, short sterilization time, and the effect of reducing comprehensive use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

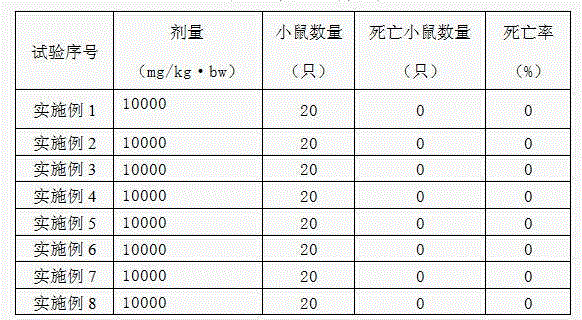

Examples

Embodiment 1

[0019] Example 1: 0.5% o-phthalaldehyde, 1.0% dioctyldimethylammonium chloride, 35% propylene glycol, 3% sodium carbonate, 6% dimethyl sulfoxide, 1.5% benzotriazole, hexameta Sodium phosphate 1%, sodium thiosulfate 0.5% and purified water 51.5%.

Embodiment 2

[0020] Example 2: 1.0% o-phthalaldehyde, 3.0% dioctyldimethylammonium chloride, 30% isopropanol, 2% borate, 5% alkylphenol polyoxyethylene ether, 1.0% phosphonic acid, EDTA Disodium Salt 2.0%, Ascorbic Acid 1.0% and Purified Water 55%.

Embodiment 3

[0021] Example 3: 1.5% o-phthalaldehyde, 3.0% benzalkonium chloride, 30% isopropanol, 2% borate, 8% alkylphenol polyoxyethylene ether, 1.5% sodium phosphonate, 3% polyacrylic acid , ascorbic acid 3% and purified water 48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com