Method for producing fermentative cordycep fungal powder and cordyceps polysaccharide powder through fermentation technology

A technology for Cordyceps sinensis powder and Cordyceps sinensis, which is applied in the directions of botanical equipment and methods, applications, fungi, etc., can solve the problems of ecological environment damage, insufficient Cordyceps resources, and on the verge of depletion of Cordyceps sinensis, and achieves strong competitiveness, good market prospects, high-tech effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

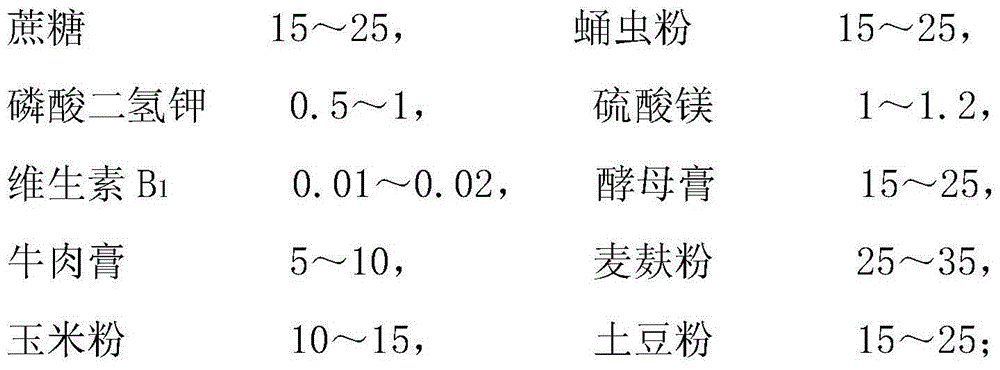

[0019] The pure strains of Cordyceps sinensis purchased from the China Industrial Microbial Culture Collection and Management Center (CICC) with the preserved strain numbers of 14106; 14107; 2002 or the China Pharmaceutical Microorganisms Collection and Management Center with the preserved strain numbers of cpcc1400031; cpcc1400051; cpcc400014 After conventional cultivation, the strains are prepared into production strains and placed on a solid comprehensive medium with a pH value of 7.0 for inoculation. The material formula per unit of the medium is: 25g of potatoes, 15g of sucrose, and dihydrogen phosphate. Potassium 0.8g, Magnesium Sulfate 1g, Vitamin B 1 0.01g, yeast extract 15g, beef extract 8g, wheat bran powder 25g, corn flour 10g, pupa powder 12g, rice flour 15g. The pure strain of Cordyceps sinensis was cultured by solid fermentation in the culture medium for 50 days, and the culture temperature was 22°C; then the culture medium was separated from the grown thalline b...

Embodiment 2

[0021] 0.5g of proteolytic enzyme, 1.0g of starch hydrolase and 0.5g of cellulose hydrolase were added to 100g of Cordyceps sinensis powder prepared according to the production method described in Example 1 in the temperature range of 15°C to 35°C. In the process, the material is stirred evenly under the condition that the water content is 60% to 90%, then the temperature is 40 ℃ to 60 ℃ and the pH value is 7.0 for 60 to 70 minutes, and then the organic solvent precipitation method is used to extract the above The polysaccharide component of the material, and then obtain a crude polysaccharide product with a content of 75% to 85% by a low-temperature freeze-drying method, and then use 0.2 g of proteolytic enzyme, 1.0 g of starch hydrolase and 0.2 g of cellulose hydrolase to separate the crude polysaccharide products. Re-extraction is carried out, and the re-extract is decolorized by adsorption method to obtain a polysaccharide refined product with a content of more than 95%.

Embodiment 3

[0023]Select fresh individuals of natural Cordyceps sinensis fruiting bodies, screen out relatively stable and better-performing strains from the fruiting bodies by conventional primary screening and re-screening methods, and then use conventional microbial system separation methods such as separation, rejuvenation and control in turn. This obtains a pure strain of Cordyceps sinensis; or directly selects a strain in the National Culture Collection Center, and after selection and rejuvenation, a pure strain of Cordyceps sinensis is obtained. The pure strain strain of Cordyceps sinensis is inserted into a liquid comprehensive medium liquid fermentation equipment with a pH value of 7.0 for inoculation, and the material raw material formula of this liquid comprehensive medium liquid is: potato powder 15g, sucrose 15g, larvae powder 15g, phosphoric acid diphosphate 15g. Potassium hydrogen 1g, magnesium sulfate 1g, vitamin B 1 0.01g, yeast extract 15g, beef extract 5g, wheat bran po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com