Heat radiation method and device for built-in electromobile battery pack

A technology for electric vehicles and heat sinks, applied in batteries, secondary batteries, circuits, etc., can solve the problems of uneven temperature distribution, poor cooling efficiency, large weight and volume of heat sinks, etc., to ensure uniform temperature distribution and low temperature. , The effect of efficient and rapid isothermal heat diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

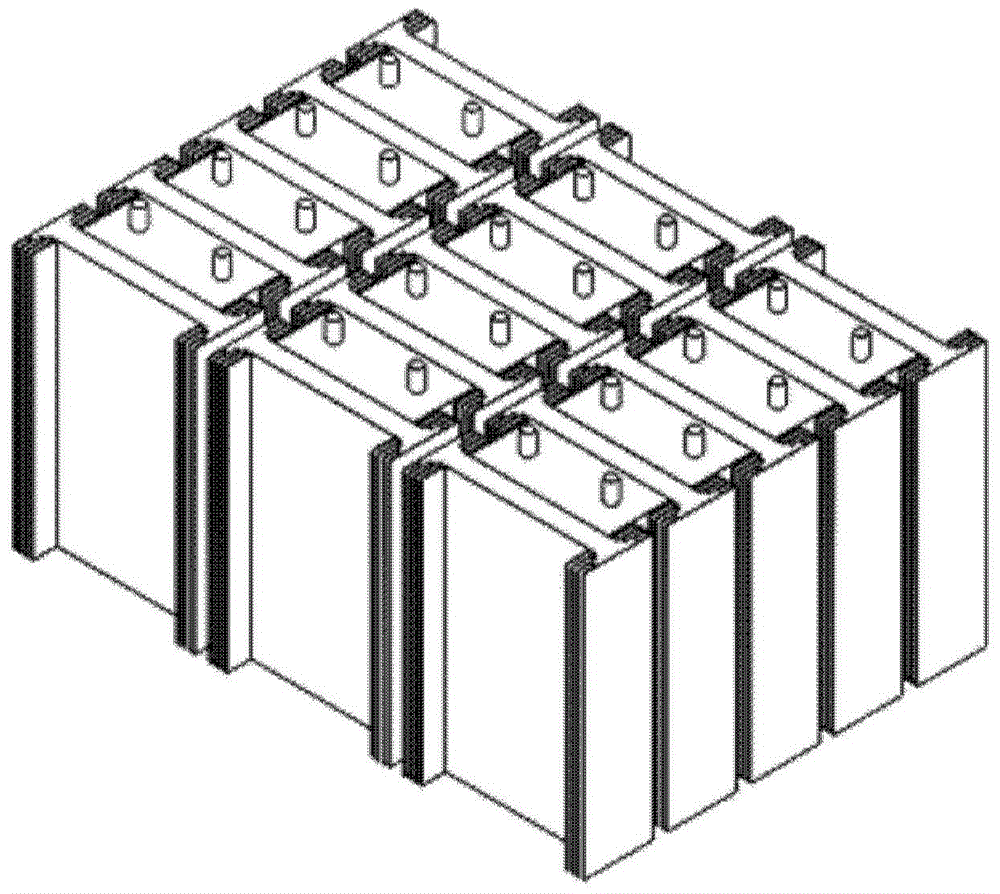

[0035] Please see attached image. For the electric vehicle battery pack battery group equipment composed of 12 high-power battery cells, a built-in electric vehicle battery group heat dissipation system with forced air cooling mode cold end is made. It includes a battery cell 1, a vacuumized "I"-shaped multi-channel micro-groove group composite phase-change cooling module 2 (such as Figure 1A and 1B shown), battery pack case 7 and fan 8 with ventilation holes on the case wall (such as image 3 and 4 shown).

[0036] see Figure 2A , 2B, 2C. Each battery cell 1 is provided with two "I"-shaped multi-channel micro-groove composite phase-change cooling modules 2, each of which takes heat from one side of the battery cell 1. The central part of each "I"-shaped multi-channel micro-groove group composite phase-change heat dissipation module 2 is a vacuumized an...

Embodiment 2

[0039] For the electric vehicle battery pack battery group equipment composed of 12 high-power battery cells, a built-in electric vehicle battery group heat dissipation system with forced liquid cooling mode cold end is made. Change the ventilation holes opened on the outer wall of the battery pack case 7 in Embodiment 1 to open the liquid inlet 9 and the liquid outlet 10 of the insulating cooling liquid entering and leaving the battery pack case 7 on the outer wall of the battery pack case 7, as Figure 4 shown. Using an external liquid pump, the insulating cooling liquid enters the battery pack box from the liquid inlet 9, and then divides into multiple flow paths, flowing from top to bottom between each adjacent two groups (two rows) of battery cells. The channel gap and the gap between the ribs 5 of each "I"-shaped multi-channel micro-groove group composite phase-change heat dissipation module 2; take away the heat of the battery cell. Other parts of this embodiment are t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com