Cobalt-nickel metal sulfide, preparation method and application thereof

A technology of sulfide and bimetal, which is applied in the field of new energy materials and devices, can solve the problems of high preparation cost and achieve the effects of low cost, good electrochemical performance and short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 The counter electrode prepared in the first step with a hydrothermal temperature of 90°C

[0015] (1) Put the clean FTO conductive glass with the conductive surface down and place it in the water heating kettle.

[0016] (2) Prepare a mixed solution with a concentration ratio of nickel nitrate: cobalt nitrate: ammonium fluoride: urea in a concentration ratio of 0.5-2.5:0.5-4:2-6:3-7.

[0017] (3) Pour the solution in (2) into the hydrothermal kettle in (1), and conduct a hydrothermal reaction at 90° C. for 1 to 8 hours.

[0018] (4) The sample obtained by the hydrothermal reaction was rinsed three times with deionized water, and dried at 60°C.

[0019] (5) Put the sample prepared above into a hydrothermal kettle.

[0020] (6) Prepare a sodium sulfide aqueous solution with a concentration of 1-5mg / ml, pour it into a hydrothermal kettle with a sample, and conduct a hydrothermal reaction at 90-160°C for 6-12 hours.

[0021] (7) Rinse the sample obtained by hyd...

Embodiment 2

[0027] Example 2 The counter electrode prepared in the first step with a hydrothermal temperature of 120°C

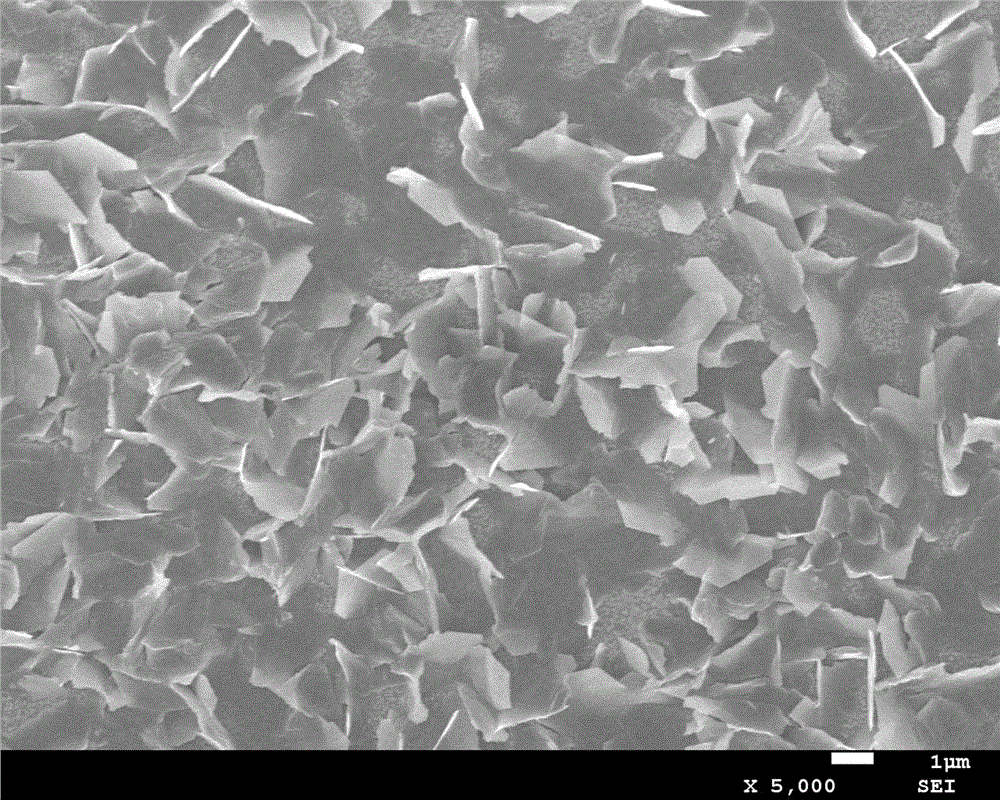

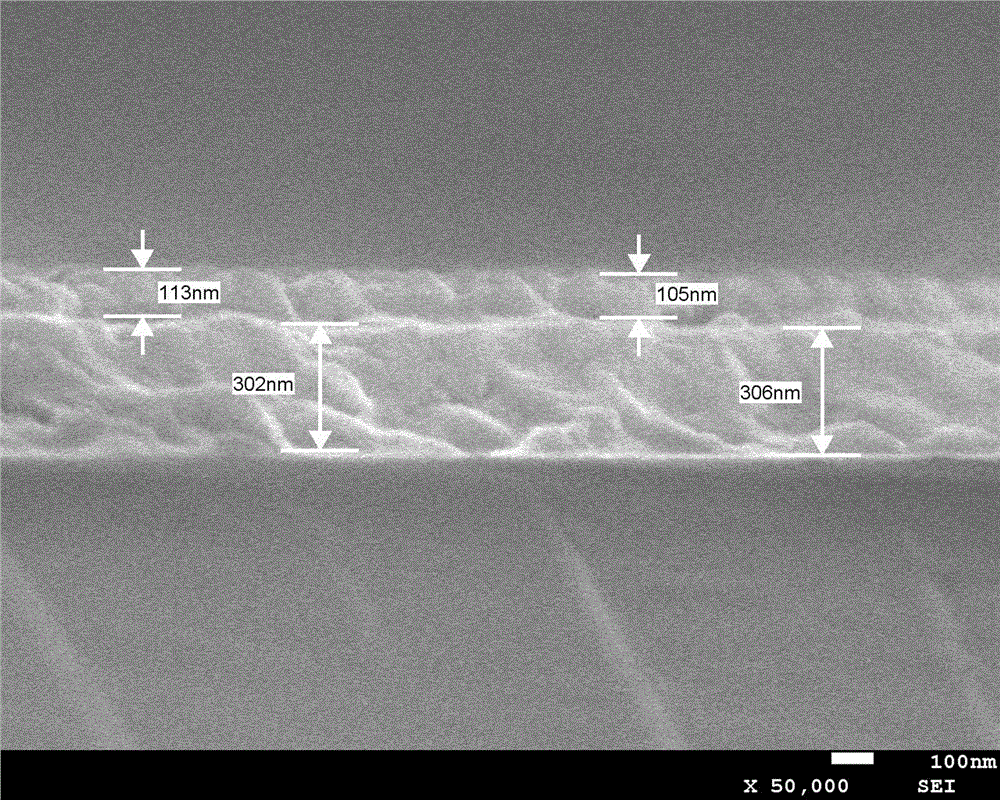

[0028] The difference between this example and Example 1 is that the hydrothermal temperature in step (3) is 120° C., and other steps and experimental conditions are the same as in Example 1. Such as image 3 and 4 The scanning electron micrographs of the surface and interface of the counter electrode were prepared under this condition. The surface of the sample presents an upright nanosheet structure perpendicular to the direction of the film surface, and the thickness of the nanosheet film is about 5 μm.

[0029] TiO 2 The preparation of the photoanode and the battery performance test method and steps are the same as those described in Example 1, and the test results are shown in Table 1 and Table 2.

[0030] Table 1: Cell performance data when light is incident from the photoanode side

[0031]

[0032] Table 2: Cell performance data when light is incident fr...

Embodiment 3

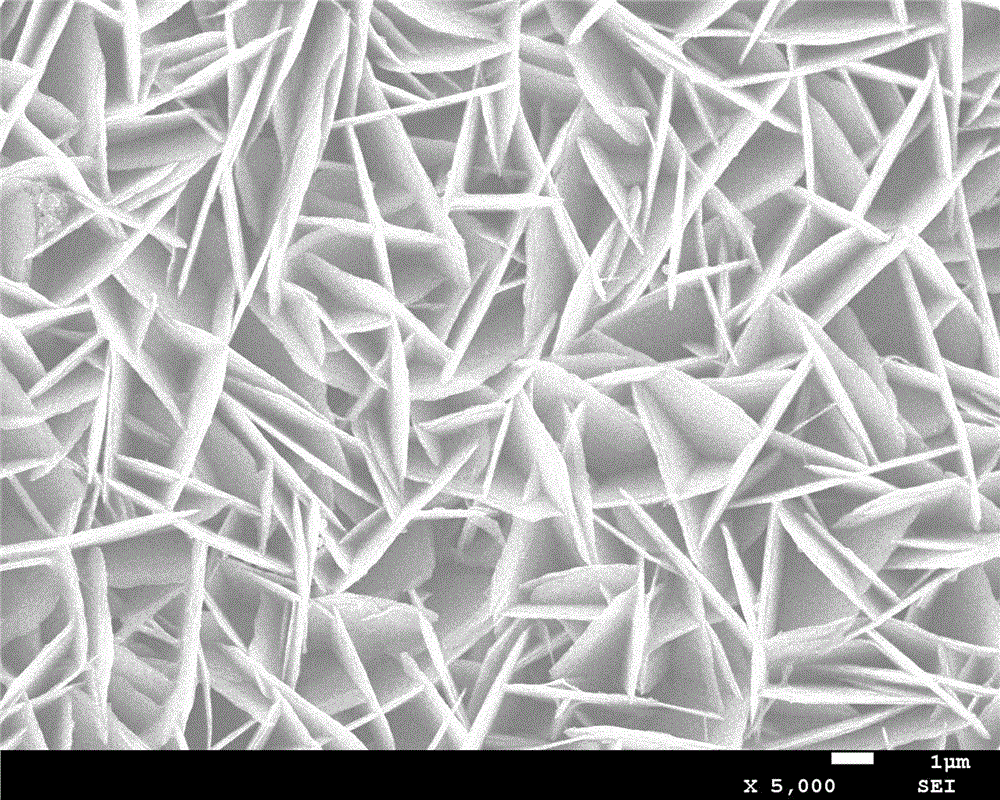

[0034] Example 3 The counter electrode prepared under the condition that the ratio of ammonium fluoride and urea is 2:3

[0035] (1) Put the clean FTO conductive glass with the conductive surface down and place it in the water heating kettle.

[0036] (2) Prepare a mixed solution with a concentration ratio of nickel nitrate: cobalt nitrate: ammonium fluoride: urea in a concentration ratio of 0.5-2.5:0.5-4:2:3.

[0037] (3) Pour the solution in (2) into the hydrothermal kettle in (1), and conduct a hydrothermal reaction at 70-140° C. for 1-8 hours.

[0038] (4) Rinse the sample obtained by hydrothermal treatment three times with deionized water, and dry at 60°C.

[0039] (5) Put the sample prepared above into the hydrothermal kettle.

[0040] (6) Prepare a sodium sulfide aqueous solution with a concentration of 1-5 mg / ml, pour it into a hydrothermal kettle with a sample, and conduct a hydrothermal reaction at 90-160°C for 6-12 hours.

[0041] (7) Rinse the sheet obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com