Modular interface temperature sensor of liquid-core optical fiber

A technology of temperature sensor and liquid core optical fiber, which is applied to thermometers, thermometers with physical/chemical changes, instruments, etc., to achieve the effects of low cost, high measurement sensitivity, and wide dynamic range of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

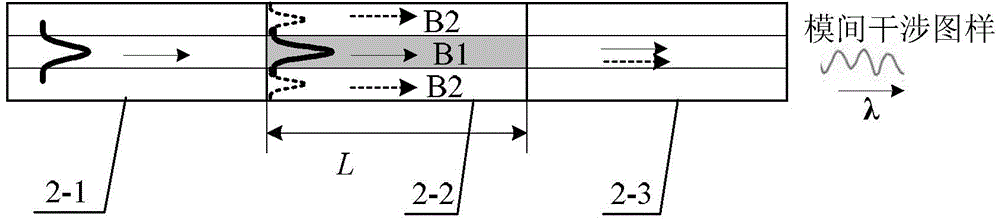

[0010] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the liquid core optical fiber intermode interference temperature sensor described in this embodiment includes an ASE broadband light source 1, a temperature sensitive module 2 and a spectrum analyzer 3, and the light beam output by the ASE broadband light source 1 is incident on the temperature sensitive module 2, The light beam output by the temperature sensitive module 2 is incident on the spectrum analyzer 3;

[0011] The temperature sensitive module 2 includes a single-mode optical fiber 2-1 at the input end, a liquid-core optical fiber 2-2 and a single-mode optical fiber 2-3 at the output end. The liquid-core optical fiber 2-2 is composed of a liquid core and a quartz cladding, and the inside of the quartz cladding is The circular center cavity is provided with a liquid fiber core;

[0012] The single-mode optical fiber 2-1 at the incident end receives the...

specific Embodiment approach 2

[0020] Embodiment 2: In this embodiment, Embodiment 1 is further described. The central wavelength of the ASE broadband light source 1 is 1550 nm or 1310 nm, and the spectral bandwidth is 40 nm to 400 nm.

specific Embodiment approach 3

[0021] Specific embodiment three: this embodiment will further explain embodiment one or two, the connection mode between the incident end single-mode optical fiber 2-1 and the liquid core optical fiber 2-2 is a fusion coupling connection; the output end single-mode optical fiber 2- 3 and the liquid core optical fiber 2-2 are connected by fusion splicing and coupling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Spectral bandwidth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com