Felt proofing method for wool fabrics

An anti-felting and fabric technology, which is applied in animal fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of complex process, expensive equipment, small molecular weight of protease, etc., and achieve simple finishing method, increased permeability, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

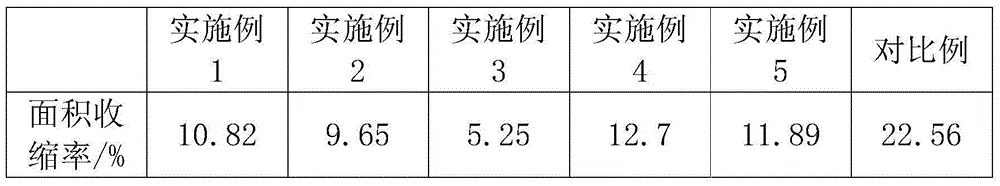

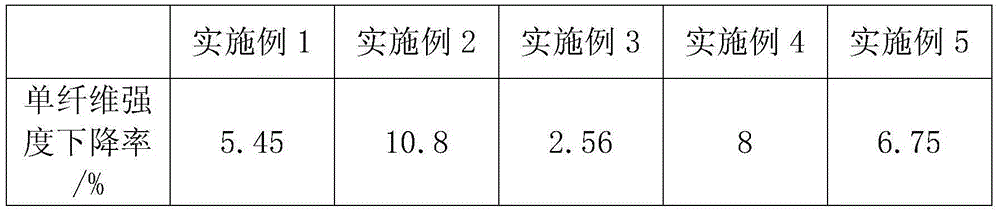

Examples

Embodiment 1

[0022] An anti-felting finishing method for wool fabrics, comprising the following steps:

[0023] (1) Weigh 10 g of protease and 80 g of deionized water, mix and stir evenly, add 4 g of polyurethane sulfonate and 2 g of silane coupling agent, heat up to 60 ° C, and ultrasonicate for 30 min at a power of 500 W to obtain a mixed dispersion;

[0024] (2) Add 1 g of nano-titanium oxide powder to the mixed dispersion liquid obtained in step (1), and ultrasonicate for 20 min at a power of 500 W to obtain an anti-felting finishing liquid;

[0025] (3) Immerse the woolen fabric in the anti-felting finishing solution obtained in step (2), the bath ratio is 1:80, ultrasonically for 10 minutes at a power of 800W, take it out, wash it with flowing water 2-3 times, and heat it at 60°C Down drying to obtain wool fabrics with anti-felting finish.

Embodiment 2

[0027] (1) Weigh 10 g of protease and 80 g of deionized water, mix and stir evenly, add 4 g of polyurethane sulfonate and 2 g of silane coupling agent, heat up to 70 ° C, and ultrasonicate for 80 min at a power of 500 W to obtain a mixed dispersion;

[0028] (2) Add 1 g of nano-titanium oxide powder to the mixed dispersion liquid obtained in step (1), and ultrasonicate for 20 min at a power of 500 W to obtain an anti-felting finishing liquid;

[0029] (3) Immerse the woolen fabric in the anti-felting finishing solution obtained in step (2), the bath ratio is 1:80, ultrasonically for 30 minutes at a power of 800W, take it out, wash it with running water 2-3 times, and heat it at 80°C Down drying to obtain wool fabrics with anti-felting finish.

Embodiment 3

[0031] (1) Weigh 10 g of protease and 80 g of deionized water, mix and stir evenly, add 4 g of polyurethane sulfonate, 2 g of silane coupling agent, heat up to 62 ° C, and ultrasonicate for 40 min at a power of 500 W to obtain a mixed dispersion;

[0032] (2) Add 1 g of nano-titanium oxide powder to the mixed dispersion liquid obtained in step (1), and ultrasonicate for 20 min at a power of 500 W to obtain an anti-felting finishing liquid;

[0033] (3) Immerse the woolen fabric in the anti-felting finishing solution obtained in step (2), the bath ratio is 1:80, ultrasonically for 15 minutes at a power of 800W, take it out, wash it with flowing water 2-3 times, and heat it at 65°C Down drying to obtain wool fabrics with anti-felting finish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com