A method for preparing a coating by thermal spraying on large-size bent pipe workpieces

A large-scale, thermal spraying technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of uniformity of coating structure and performance, bending deformation, limited rigidity, etc., to achieve coating structure And the effect of good performance uniformity, prevention of workpiece deformation, and convenient replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

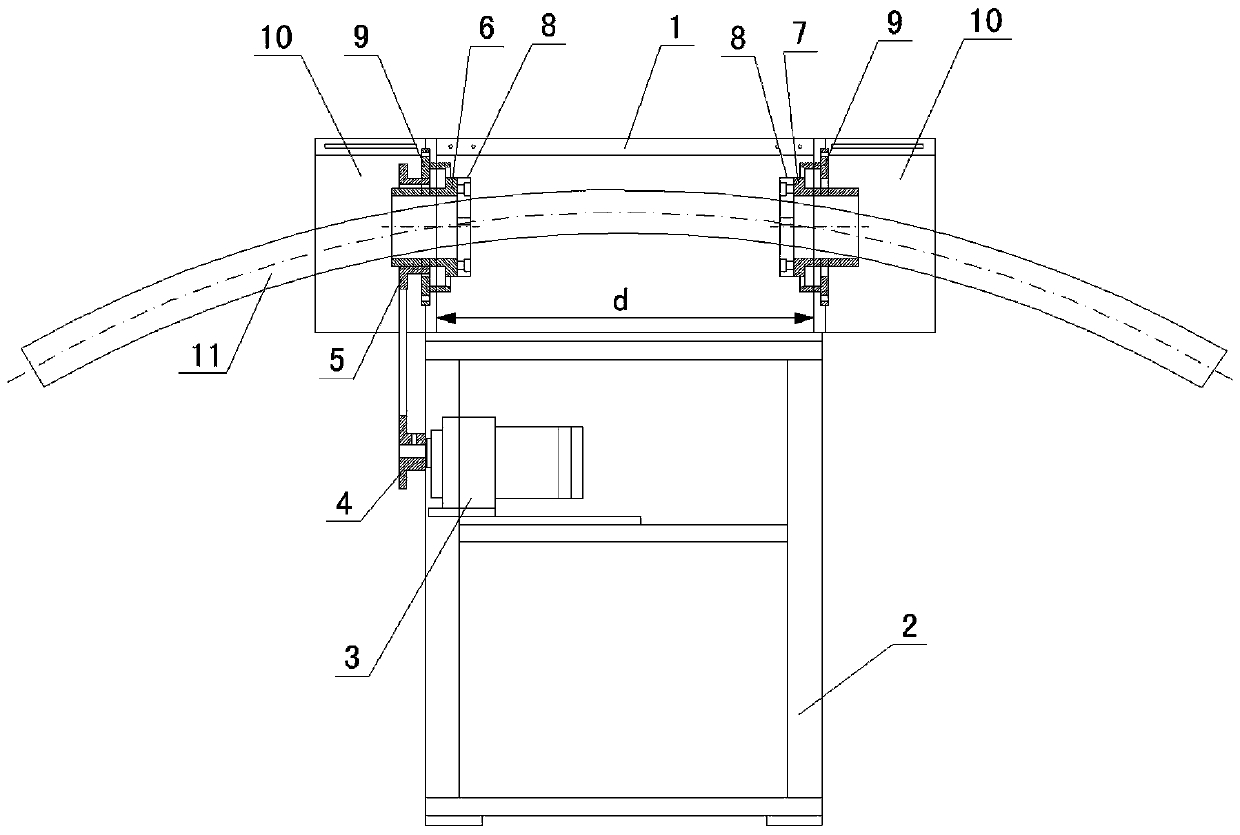

[0029] like Figure 1-Figure 4 As shown, the method for preparing a coating by thermal spraying on a large-size elbow class workpiece according to the present invention comprises the following steps:

[0030] Step 1: Use the conventional treatment process to clean the surface of large-sized elbow workpieces, shield the non-coated parts and roughen the surface of the parts to be sprayed;

[0031] Step 2: Clamp and fix the workpiece with specially designed elbow spraying tooling;

[0032] Step 3: When spraying, the spray gun moves along a specially designed trajectory, that is, spraying once along the A trajectory, B trajectory and C trajectory respectively is a spraying pass, repeating multiple passes until the required coating thickness is obtained , using air curtain to cool the workpiece while spraying;

[0033] Step 4: After the spraying is completed, the workpiece is disassembled from the elbow spraying tool, and after the workpiece is subjected to subsequent conventiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com