Novel quenching ring for entrained-bed gasifier

A fluidized bed gasifier and chilling ring technology, which is applied in the mechanical details of gasification units, the manufacture of combustible gases, and the petroleum industry, can solve the problems of reduced life, high temperature, and difficulty in manufacturing and assembly, and can reduce manufacturing costs and costs. The effect of processing cost, high material utilization rate and reduction of spare parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

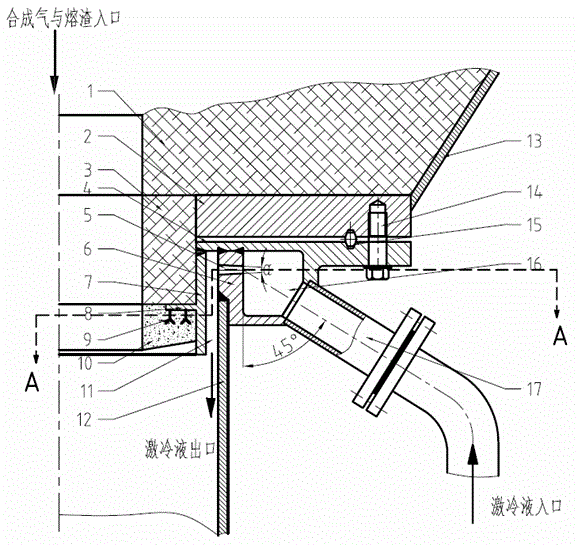

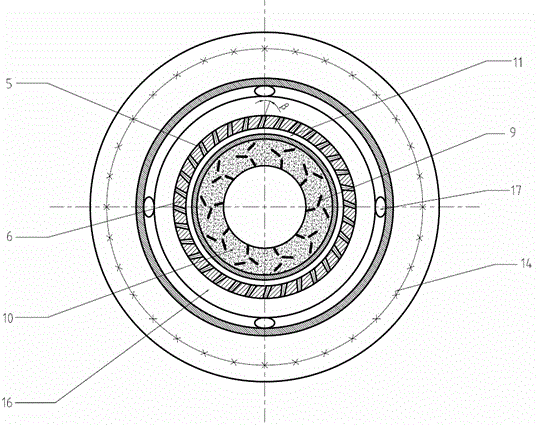

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0029] like Figure 1-2 As shown, a novel fluidized bed gasification furnace quenching ring of the present invention includes an annular outer ring plate 4, an annular inner ring plate 7, an annular spacer ring 6, a downcomer 12, a quenching liquid delivery pipe 17, and an annular The outer ring plate 4 comprises a horizontal annulus and a longitudinal annulus below the horizontal annulus. The annular inner ring plate 7 and the annular spacer ring 6 are all fixed on the inner side of the horizontal annulus of the annular outer ring plate 4. The spacer ring 6 is located between the annular inner ring plate 7 and the longitudinal ring surface 1 of the annular outer ring plate, and the downcomer 12 is installed at the lower end of the annular spacer ring 6; A quenching liquid distribution chamber 16 is formed between the ring surfaces, and the que...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com