Hydrocracking process

A hydrocracking and hydrorefining technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of difficulty in taking into account the quality of reformate and tail oil products, poor hydrogenation selectivity, etc. Good economic benefits, improve cracking rate, improve the effect of aromatic potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

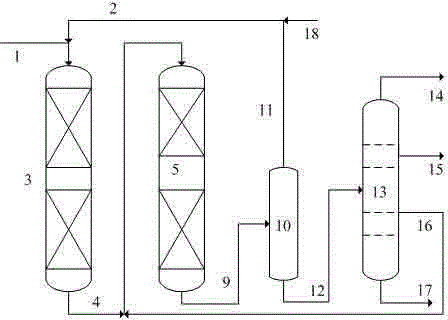

[0031] Embodiment 1-3 adopts figure 1 process shown. In Examples 1-3, the hydrogenation pretreatment reactor was filled with FF-36 catalyst, and the hydrocracking reactor was loaded with different proportions of bulk phase catalysts and hydrocracking catalysts according to the order of the catalyst bed from top to bottom. catalyst. In the three examples, the ratios of bulk catalyst and cracking catalyst 1 in the three mixed catalyst beds are 3:1, 1:1, 0; 3:1, 2:1, 1:1 and 1: 1;1:2;1:3.

[0032] The composition and properties of the catalyst are shown in Table 1, the properties of the raw materials used are shown in Table 2, and the reaction conditions and reaction results of Examples 1-3 are shown in Table 3 and Table 4 below.

Embodiment 4

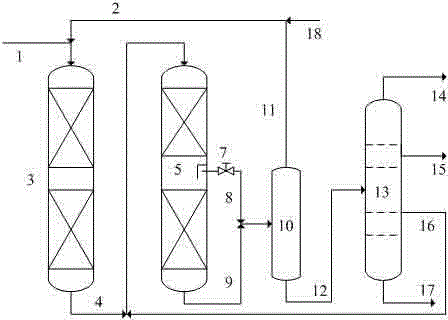

[0034] use figure 2 process shown. Feedstock oil, and catalyst used are the same as embodiment 3. Wherein a gas extraction pipeline is set between the second and third cracking catalyst beds, and the others are the same as in Embodiment 3. The amount of gas phase material drawn from the gas phase extraction pipeline is 30% of the amount of circulating hydrogen.

[0035] Table 1 The composition and main properties of the catalysts used in the examples.

[0036] project FTX Cracking Catalyst 1 Cracking Catalyst 2 Chemical composition, mass% MoO 3 16 — — NiO 18 4 6 WO 3 42 18 22 margin Aluminum oxide Alumina + molecular sieve Alumina + molecular sieve carrier Aluminum oxide Aluminum oxide Aluminum oxide cracking components — Y molecular sieve Y molecular sieve Content, m% — 70 70

[0037] Table 2 Raw oil properties.

[0038] Raw oil Raw oil Density, g / cm 3 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com