Composite catalyst, preparation method and application thereof, and method for preparing aromatic hydrocarbon from synthesis gas through one-step method

A composite catalyst, synthesis gas technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from carbon oxides, etc., can solve the problems of high CO conversion and aromatics selectivity, and achieve improved aromatics selectivity and stability. , the effect of increasing the surface oxygen vacancy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

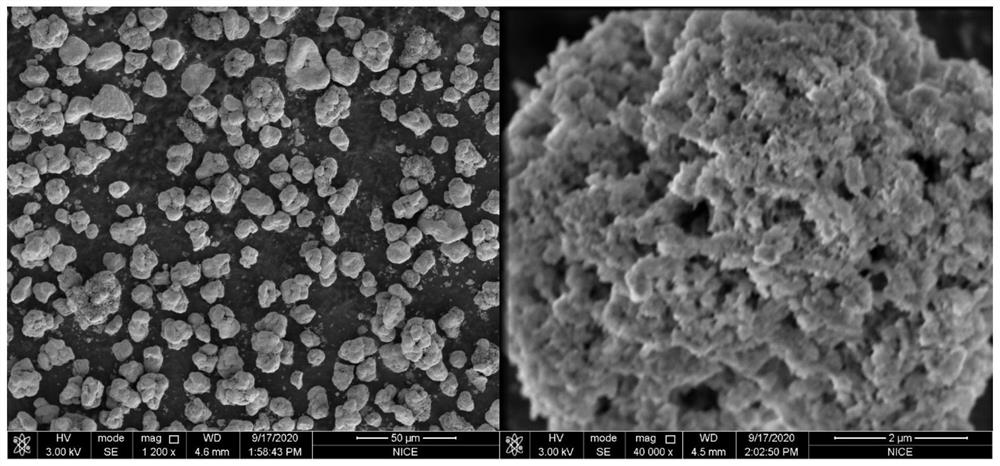

[0078] Preparation of metal oxides :

[0079] (1) 10.125g Al (NO 3 ) 3 ·9H 2 O was dissolved in 50 mL of deionized water to obtain an aluminum salt solution; at 50 °C, the aluminum salt solution was mixed with (NH 4 ) 2 CO 3 Co-precipitation is carried out at a molar ratio of 1:1.5 to obtain a first mixture, wherein the aluminum salt solution is made of Al 3+ the mole meter;

[0080] (2) 60gCr (NO 3 ) 3 ·5H 2 O, 17.86gZn(NO 3 ) 2 ·9H 2 O, 10.77gMn (NO 3 ) 2 Dissolve in 250 mL of deionized water, stir continuously until all dissolved, then dilute to 300 mL to obtain a mixed salt solution; raise the temperature to 70 ° C, add mixed salt solution to the first mixture, and then add (NH 4 ) 2 CO 3 Carry out co-precipitation and adjust the pH value to 7.5 to obtain the second mixture;

[0081] (3) After aging the second mixture at 70°C for 5h, carry out suction filtration, wash the filter cake to neutrality, dry at 90°C for 12h, and finally calcinate at 350°C for ...

Embodiment 2

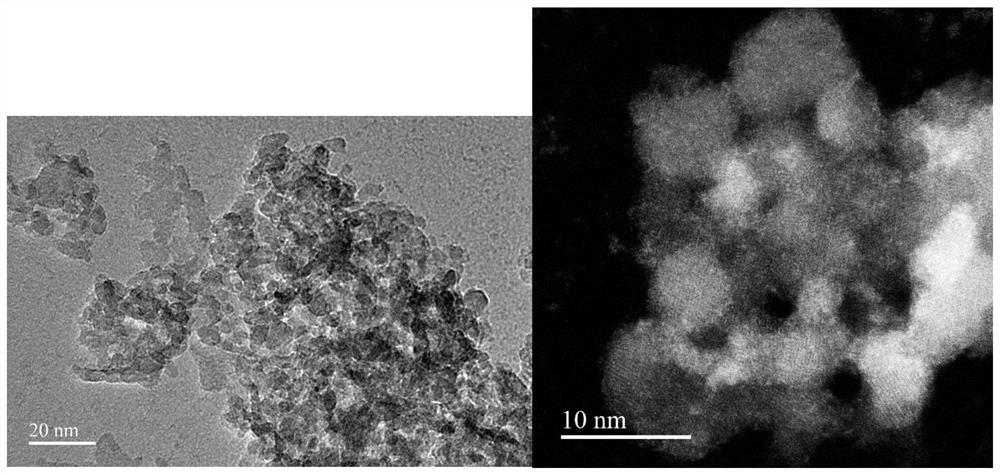

[0090] Preparation of metal oxides :

[0091] (1) 10.125g Al (NO 3 ) 3 ·9H 2 O was dissolved in 50 mL of deionized water to obtain an aluminum salt solution; at 50 °C, the aluminum salt solution was mixed with (NH 4 ) 2 CO 3 Co-precipitation is carried out at a molar ratio of 1:1.5 to obtain a first mixture, wherein the aluminum salt solution is made of Al 3+ the mole meter;

[0092] (2) 60gCr (NO 3 ) 3 ·5H 2 O, 26.79gZn(NO 3 ) 2 ·9H 2 O, 10.77gMn (NO 3 ) 2 Dissolve in 250 mL of deionized water, stir continuously until all dissolved, then dilute to 300 mL to obtain a mixed salt solution; raise the temperature to 70 ° C, add mixed salt solution to the first mixture, and then add (NH 4 ) 2 CO 3 Carry out co-precipitation and adjust the pH value to 7.5 to obtain the second mixture;

[0093] (3) After aging the second mixture at 70°C for 10h, carry out suction filtration, wash the filter cake to neutrality, dry at 90°C for 15h, and finally calcinate at 350°C for...

Embodiment 3

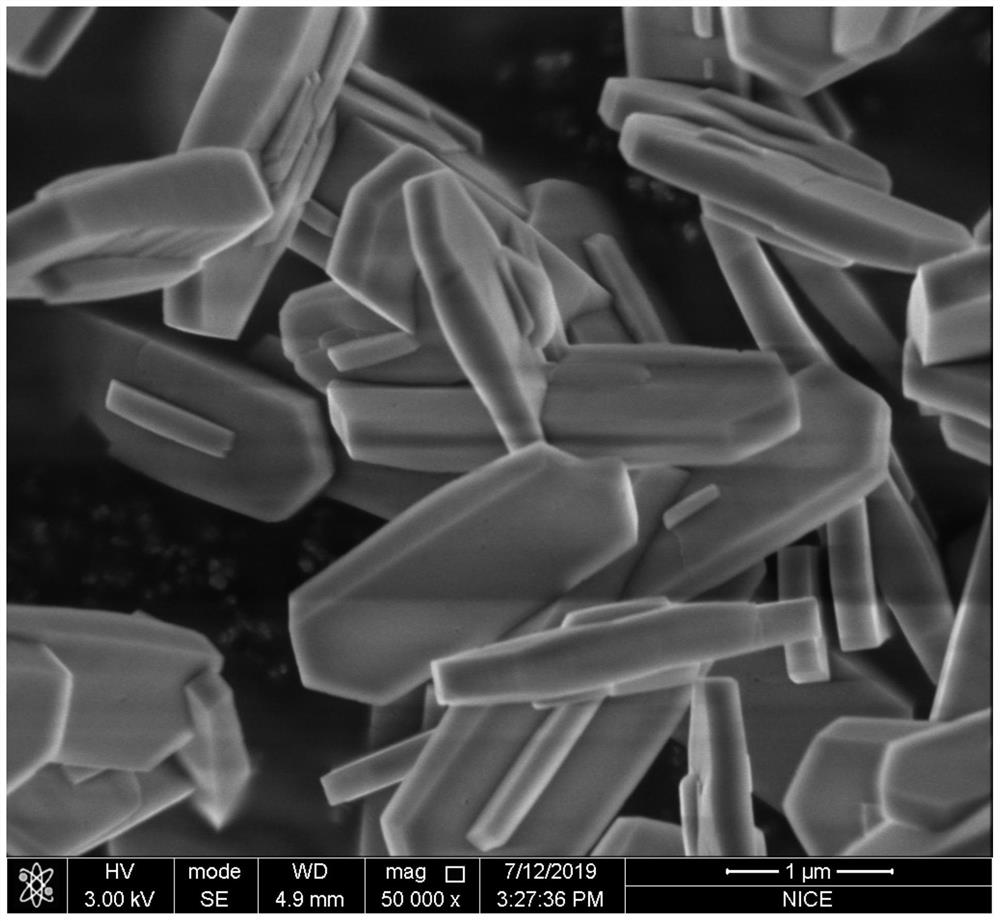

[0100] Preparation of metal oxides :

[0101] (1) 10.125g Al (NO 3 ) 3 ·9H 2 O was dissolved in 50 mL of deionized water to obtain an aluminum salt solution; at 50 °C, the aluminum salt solution was mixed with (NH 4 ) 2 CO 3 Co-precipitation is carried out at a molar ratio of 1:1.4 to obtain a first mixture, wherein the aluminum salt solution is made of Al 3+ the mole meter;

[0102] (2) 60gCr (NO 3 ) 3 ·5H 2 O, 26.79gZn(NO3 ) 2 ·9H 2 O, 16.07gMn (NO 3 ) 2 Dissolved in 250 mL of deionized water, stirring continuously, until all dissolved, then the volume was adjusted to 270 mL to obtain a mixed salt solution; the temperature was raised to 70 ° C, the mixed salt solution was added to the first mixture, and then (NH 4 ) 2 CO 3 Carry out co-precipitation and adjust the pH value to 7.5 to obtain the second mixture;

[0103] (3) After aging the second mixture at 70°C for 10h, carry out suction filtration, wash the filter cake to neutrality, dry at 90°C for 15h, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com