Preparation method and application method of saline-alkali soil conditioner

A technology of soil conditioner and saline-alkali land, applied in the field of composite material preparation, can solve the problems of low return rate, long time-consuming, large investment, etc., and achieve the effects of increasing nutrient absorption, improving stress resistance, and promoting root system development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

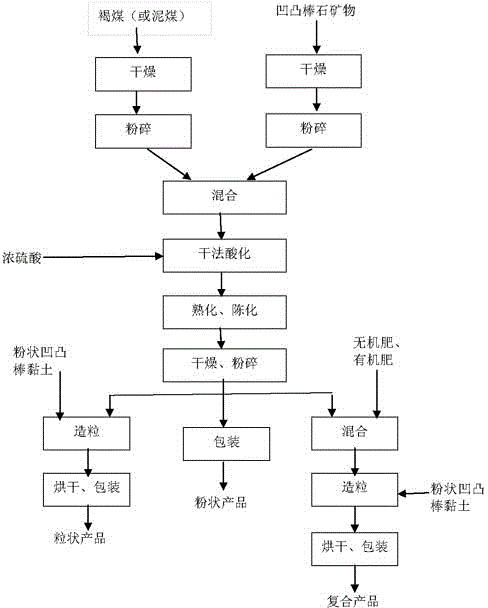

[0022] A preparation method of soil conditioner for saline-alkali land is as follows: respectively drying and pulverizing lignite and attapulgite minerals containing humic acid, then mixing according to a ratio of 1:1, adding to a continuous reactor, and simultaneously spraying 110% of the total weight of the mixture % concentrated sulfuric acid, the reaction product falls into the aging chamber, and is kept at a heat preservation for 24 hours, so that the reaction tends to be complete. After the mature material is crushed, it is packed in a fiber-woven inner plastic film bag to obtain a powdery product. The process route is attached figure 1 shown.

Embodiment 2-5

[0024] A method for preparing a soil conditioner for saline-alkali land, the preparation method and process route are as in Example 1, and the consumption quota is as shown in Table 1.

[0025]

Embodiment 6-8

[0027] A preparation method of a soil conditioner for saline-alkali land: dry and pulverize lignite and attapulgite minerals containing humic acid respectively, then mix them in a ratio of 1:1, add them to a continuous reactor, and spray 110% of the total weight of the mixture at the same time Concentrated sulfuric acid, the reaction product falls into the aging bin, and is kept for 24 hours at heat preservation, so that the reaction tends to be complete. After the mature material is pulverized, it is added to the continuous reactor, and at the same time, 15% powdery attapulgite clay and an appropriate amount of water are added, granulated, dried and made into granules, and packed in fiber-woven plastic film bags lined with it, and used as granular products. The process route is attached figure 1 shown. The consumption quota is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com