A device and method for treating refractory organic matter in high-concentration waste hydrochloric acid

A technology for refractory organic matter and waste hydrochloric acid, which is applied in the field of devices for treating refractory organic matter in high-concentration waste hydrochloric acid, can solve problems such as unsatisfactory effects, achieve remarkable treatment effects, simple treatment process, and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

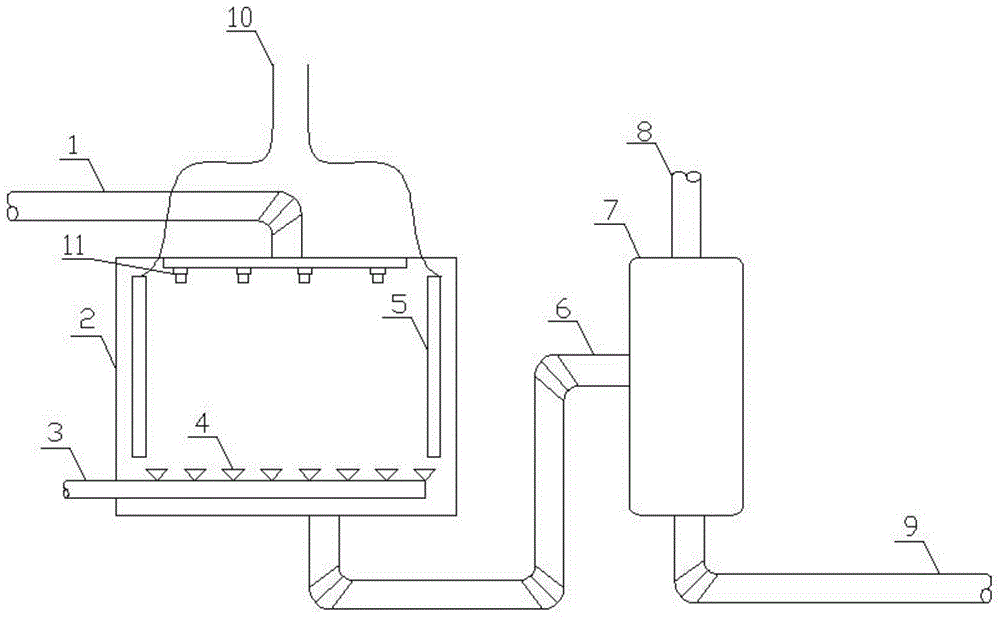

Image

Examples

Embodiment 1

[0018] Embodiment 1: COD is 200mg / L, and the waste hydrochloric acid that hydrochloric acid concentration is 12mol / L is passed into reactor 2, releases hydrogen simultaneously to form gas-liquid mixture, every processing 1L of waste hydrochloric acid adds the hydrogen of 20ml; Utilization power is 10kw The pulse power supply 10 generates a pulse voltage with a frequency of 1000HZ and an average voltage of 440V, which is discharged through the electrode plate 5, and the hydraulic retention time (ie, the reaction time of waste hydrochloric acid per unit mass in the reactor 2) is 20 minutes. The COD in the degraded waste hydrochloric acid was 52 mg / L, and the removal rate of organic matter was 74.0%.

Embodiment 2

[0019] Embodiment 2: COD is 240mg / L, and the waste hydrochloric acid that hydrochloric acid concentration is 12mol / L is passed into reactor 2, releases hydrogen at the same time to form gas-liquid mixture, every processing 1L of waste hydrochloric acid adds the hydrogen of 15ml; Utilization power is 5kw The pulse power supply 10 generates a pulse voltage with a frequency of 1000HZ and an average voltage of 440V, which is discharged through the electrode plate 5, and the hydraulic retention time is 30min. The COD in the degraded waste hydrochloric acid was 52 mg / L, and the removal rate of organic matter was 78.3%.

Embodiment 3

[0020] Embodiment 3: COD is 211mg / L, and the waste hydrochloric acid that hydrochloric acid concentration is 8mol / L is passed into reactor 2, releases hydrogen simultaneously to form gas-liquid mixture, every processing 1L of waste hydrochloric acid adds the hydrogen of 20ml; Utilization power is 20kw The pulse power supply 10 generates a pulse voltage with a frequency of 1000HZ and an average voltage of 440V, which is discharged through the electrode plate 5, and the hydraulic retention time is 10 minutes. The COD in the degraded waste hydrochloric acid was 60 mg / L, and the removal rate of organic matter was 71.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com