Needle brush smooth flow device for utensil distillation equipment

A technology of distillation equipment and needle brush, applied in the field of distillation, can solve the problems of Xiaoqu sorghum wine loss, breakage, air leakage at the connection of the retort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

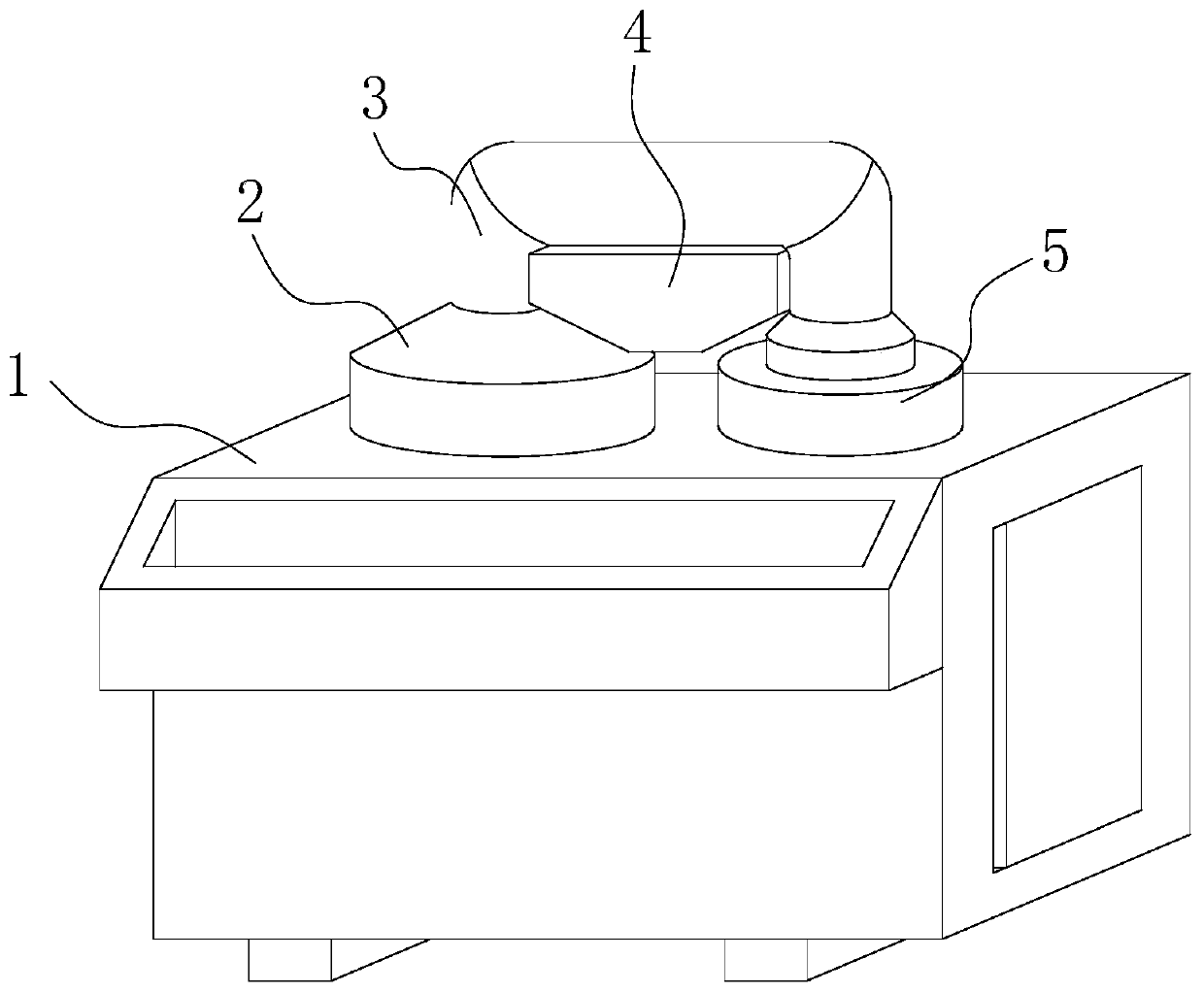

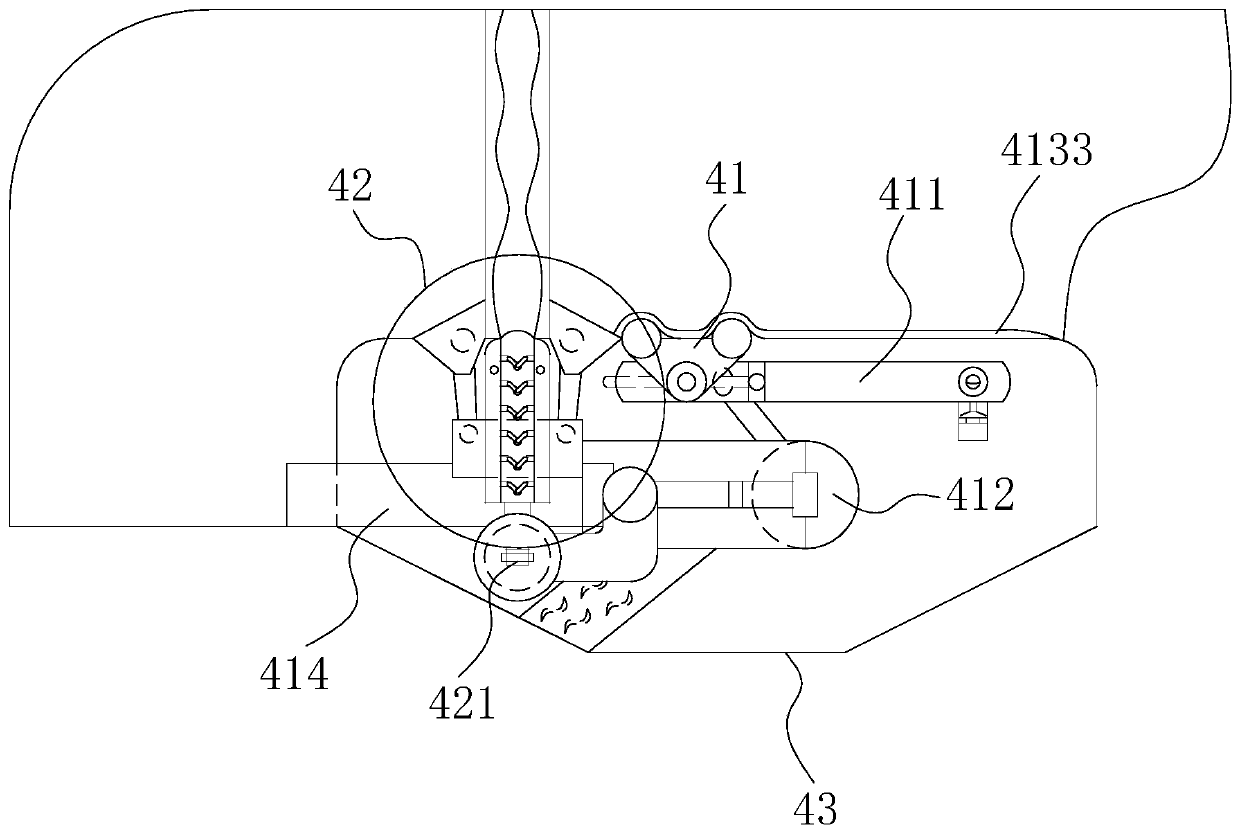

[0026] Such as Figure 1-Figure 7 As shown, the present invention provides a needle brush smooth flow device for retort distillation equipment, its structure includes a box body 1, a retort barrel 2, a drainage tube 3, a needle brush smooth flow device 4, and an ice bucket 5, and the retort bucket 2 is embedded Installed inside the box body 1, the drainage tube 3 communicates with the retort bucket 2, the needle brush smooth flow device 4 is horizontally installed on the lower end surface of the drainage tube 3, and the ice bucket 5 connects with the steamer bucket through the drainage tube 3 2 connected, the needle brush smooth flow device 4 includes a convex guide mechanism 41, a pushing mechanism 42, and a housing 43, and the convex guide mechanism 41 is installed horizontally inside the housing 43, and the convex guide mechanism 41 passes through the trachea With push mechanism 42 mechanical transmissions.

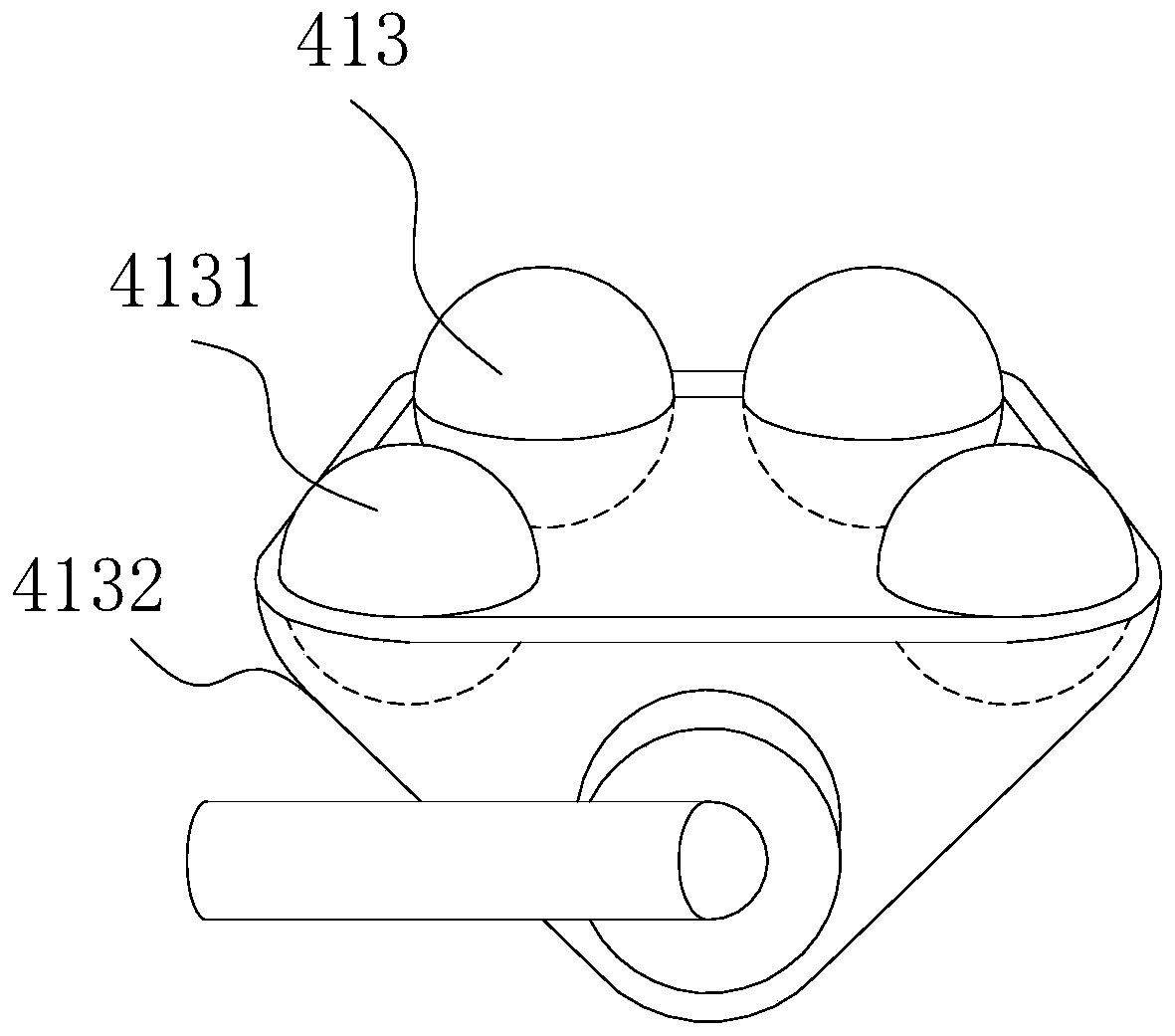

[0027] The protruding guide mechanism 41 includes a push tube 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com