Printing method

A technology for printing coatings and inks, which can be used in printing, printing devices, etc., to solve problems such as jagged edges of markings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

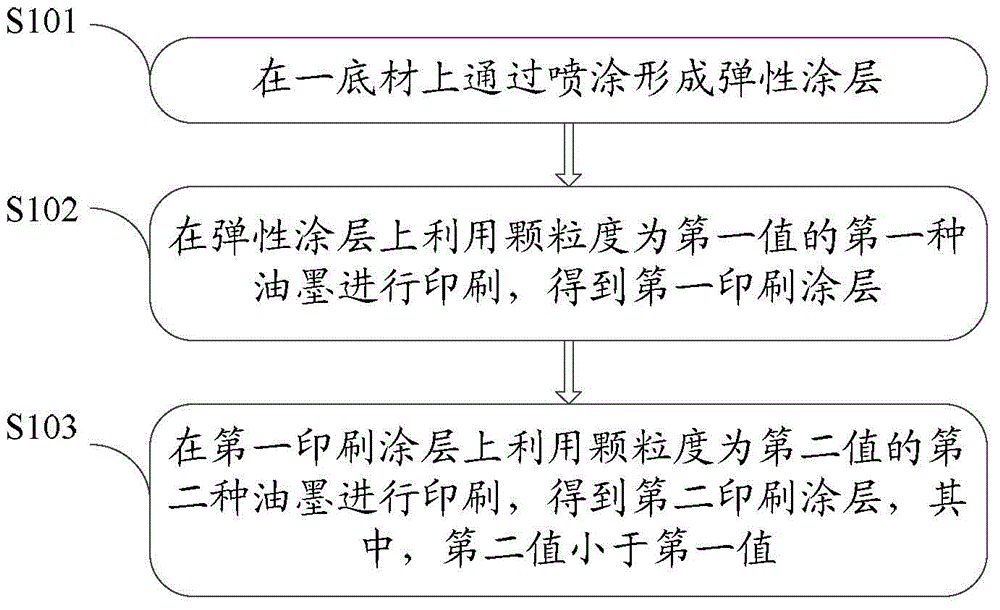

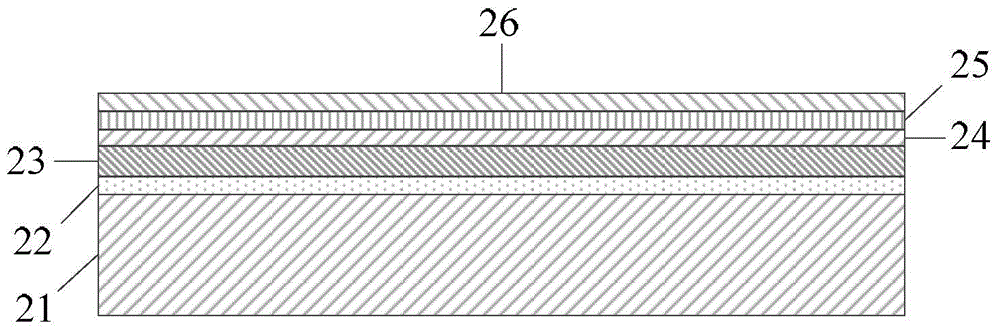

[0063] In the embodiment of this application, taking printing the logo on the back of the tablet computer as an example, ink printing is performed three times. After the three printings are completed, the schematic diagram of the surface structure of the bottom plate is as follows figure 2 shown.

[0064] In the specific implementation process, the following steps are included:

[0065] Step 1: Before printing, the workpiece needs to be pretreated according to the substrate 21 , that is, the material of the back of the tablet computer and product requirements, such as grinding, polishing, and degreasing.

[0066] Step 2: Form a colored paint coating 22 on the substrate 21 by spraying, and then dry it. In the embodiment of the present application, silver colored paint is used as an example.

[0067] The third step: spray on the paint coating 22 to form an elastic coating 23, and dry it. In the embodiment of the application, the elastic coating 23 is a transparent coating.

...

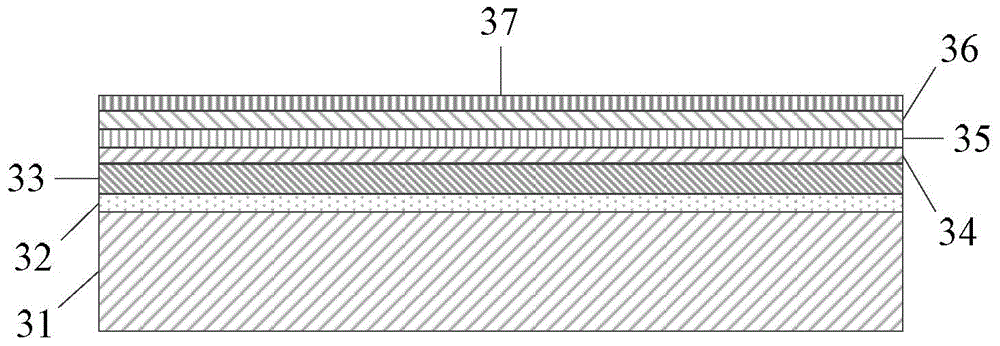

Embodiment 2

[0073] In the embodiment of this application, taking the printed matter as the back cover of a smart phone as an example, the logo of this smart phone has always been a black logo, printed at the center of the bottom of the back cover, and for the purpose of using the smart phone The elastic feel is better. This smartphone uses an elastic coating sprayed on the surface of the back cover to achieve a better elastic feel. The surface roughness of the elastic sub-coating detected by the roughness detector is 46 μm, but human It cannot be felt by touch.

[0074] In a practical application, it is assumed that the smartphone has always used a black logo. Since a smartphone usually has casings of different colors, the back covers of the smartphone are respectively white and black as an example. When the matte black logo is printed on the white back cover, the logo will appear very eye-catching and highly recognizable, but when the matte black logo is printed on the black back cover, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com