Organic sulphur hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and organic sulfur technology, applied in the field of desulfurization, can solve problems such as poor catalytic performance, achieve good mechanical properties, reduce dosage, and improve synergistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

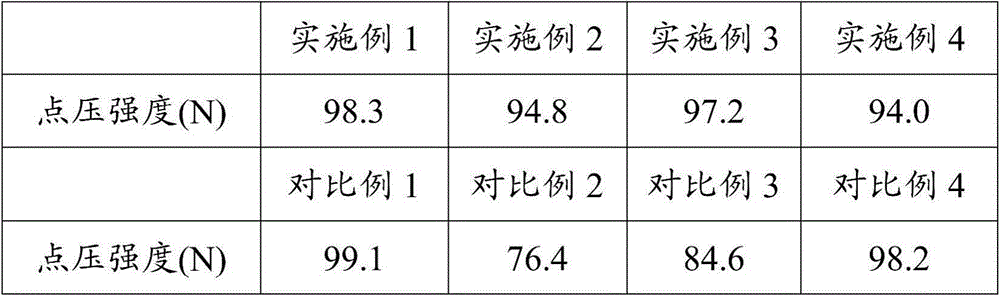

Examples

Embodiment 1

[0034] The organosulfur hydrogenation catalyst described in this embodiment is prepared from the following raw materials:

[0035] 80 parts by weight of carrier, 5 parts by weight of iron nitrate, 1 part by weight of ammonium molybdate, and 4 parts by weight of cobalt nitrate.

[0036] In this embodiment, the preparation method of the carrier is:

[0037] (1) Mixing the alumina powder with a mass ratio of 1:1 and the activated carbon powder with a particle diameter of 0.3mm, adding the scallop powder aqueous solution with a 5wt% safflower powder content, to make balls with a diameter of 4mm;

[0038] (2) Mix alumina powder with a mass ratio of 2:1:0.05, activated carbon powder and titanium dioxide powder with a particle size of 90 μm to obtain a mixture, put the balls into rolling equipment, and use the content of the scallop powder After wetting the surface of the ball nut with a 5 wt% aqueous solution of celadon powder, then alternately adding the mixture and the aqueous so...

Embodiment 2

[0043] The organosulfur hydrogenation catalyst described in this embodiment is at least prepared from the following raw materials:

[0044] 100 parts by weight of carrier, 15 parts by weight of ammonium metatungstate, 15 parts by weight of cobalt nitrate, 20 parts by weight of nickel chloride, and 5 parts by weight of zinc nitrate.

[0045] In this embodiment, the preparation method of the carrier is:

[0046] (1) Mixing the alumina powder with a mass ratio of 3:1 and the activated carbon powder with a particle size of 0.65mm, adding a kaolin aqueous solution with a kaolin content of 1wt%, to make a ball with a diameter of 3mm;

[0047] (2) Mix alumina powder with a mass ratio of 1:1:0.075, activated carbon powder with a particle size of 100 μm, and zirconium chloride powder to obtain a mixture, put the balls into rolling equipment, and use the kaolin content After wetting the surface of the ball nut with a 1 wt% kaolin aqueous solution, the mixture and the kaolin aqueous sol...

Embodiment 3

[0052] The organosulfur hydrogenation catalyst described in this embodiment is prepared from the following raw materials:

[0053] 90 parts by weight of the carrier, 15 parts by weight of copper nitrate, 15 parts by weight of zinc nitrate, and 2.5 parts by weight of nickel nitrate.

[0054] In this embodiment, the preparation method of the carrier is:

[0055] (1) Mix the alumina powder with a mass ratio of 2:1 and the activated carbon powder with a particle diameter of 1mm, add attapulgite aqueous solution with attapulgite content of 3wt%, and make a ball nut with a diameter of 5mm;

[0056] (2) Alumina powder with a mass ratio of 3:1:0.1, activated carbon powder and cerium nitrate powder with a particle size of 80 μm are mixed uniformly to obtain a mixture, and the ball nuts are put into rolling equipment, and the attapulgite is used to After the attapulgite aqueous solution with a content of 3wt% wets the surface of the ball nut, the mixture and the attapulgite aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com