Coconut juice beverage and preparation method thereof

A technology for beverage and coconut juice, applied in the field of coconut juice beverage and its preparation, can solve the problems of long shelf life, single type and taste, etc., and achieve the effects of easy absorption, simple and fast production process, and low production environment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

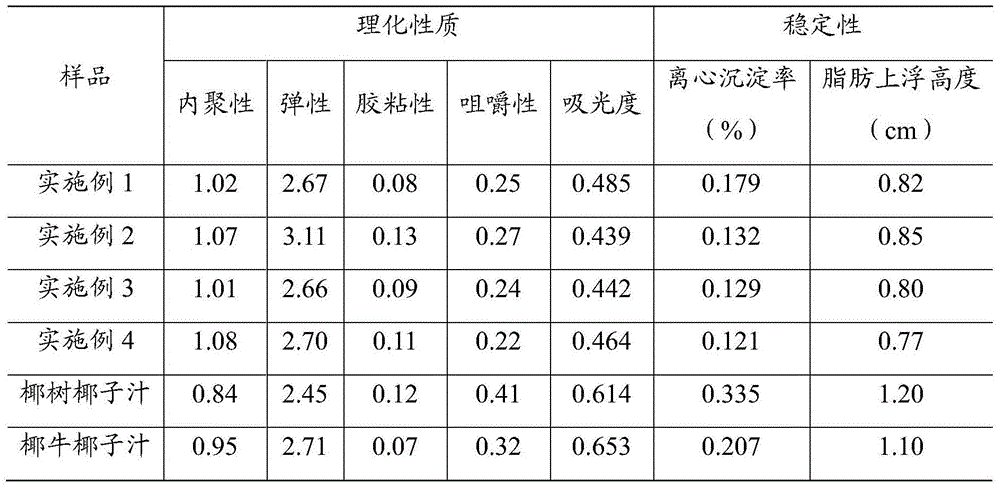

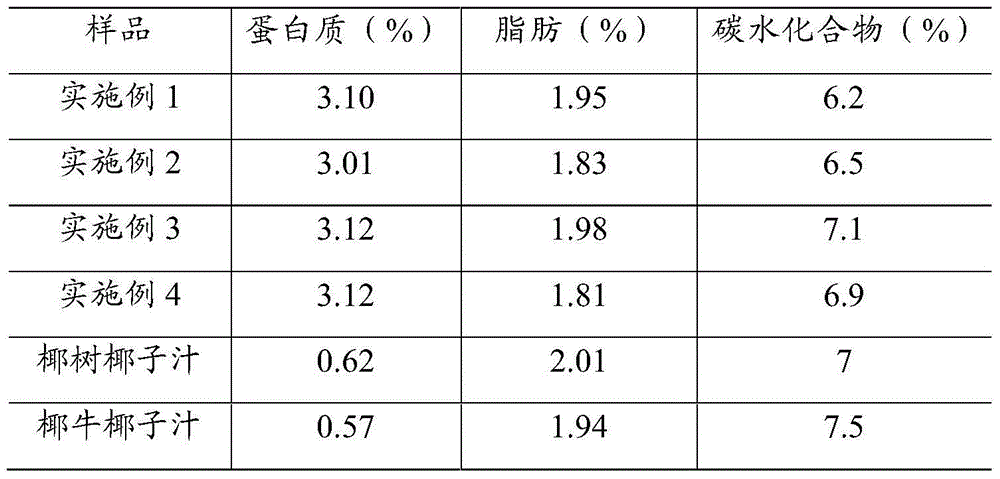

Examples

Embodiment 1

[0022] A kind of coconut juice drink component is as follows: coconut milk 7kg, white granulated sugar 4kg, soybean protein isolate 2kg, glycerin fatty acid ester 0.4kg, colloid 0.05kg, water 86.55kg.

[0023] The preparation method is as follows:

[0024] 1) Juicing: rinsing 30kg of fresh coconut meat, grinding it into powder, adding 45kg of water at 70°C to squeeze the juice three times continuously, and filtering to obtain the coconut milk.

[0025] 2) Emulsification: Mix 2 kg of soybean protein isolate, 0.4 kg of fatty acid ester of oil, and 0.05 kg of colloid, add 41.55 kg of water at 70° C. and stir to dissolve to prepare mixed solution I.

[0026] 3) Blending: Mix 7 kg of coconut milk, mixed solution I, and 4 kg of white granulated sugar, and stir well to obtain mixed solution II.

[0027] 4) Homogenization: After the mixed liquid II is subjected to first-level homogenization and second-level homogenization, wherein, the pressure of the first-level homogenization is 38...

Embodiment 2

[0030] A kind of coconut juice drink component is as follows: coconut milk 8kg, white granulated sugar 5kg, soybean protein isolate 3kg, sucrose fatty acid ester 0.6kg, dextrin 0.08kg, water 83.32kg.

[0031] The preparation method is as follows:

[0032] 1) Juicing: Rinse 40kg of fresh coconut meat, grind it into powder, add 60kg of water at 80°C to squeeze the juice three times continuously, and filter to obtain the coconut milk.

[0033] 2) Emulsification: Mix 3 kg of soybean protein isolate, 0.6 kg of sucrose fatty acid ester, and 0.08 kg of dextrin, add 23.32 kg of water at 80° C. and stir to dissolve to prepare a mixed solution I.

[0034] 3) Blending: Mix 8 kg of coconut milk, mixed solution I, and 5 kg of white granulated sugar, and stir well to obtain mixed solution II.

[0035] 4) Homogenization: After the mixed solution II is subjected to first-level homogenization and second-level homogenization, wherein, the pressure of the first-level homogenization is 35MPa, an...

Embodiment 3

[0038] A kind of coconut juice drink composition is as follows: coconut milk 10kg, white granulated sugar 7kg, skimmed milk powder 3.5kg, sucrose fatty acid ester 0.8kg, colloid 0.1kg, water 78.6kg.

[0039] The preparation method is as follows:

[0040] 1) Juicing: Rinse 20 kg of fresh coconut meat, grind it into powder, add 30 kg of water at 100° C. to squeeze the juice three times continuously, and filter to obtain the coconut milk.

[0041] 2) Emulsification: Mix 3.5 kg of skimmed milk powder, 0.8 kg of sucrose fatty acid ester, and 0.1 kg of pectin, add 48.6 kg of water at 100° C. and stir to dissolve to obtain a mixed solution I.

[0042] 3) Blending: Mix 10 kg of coconut milk, mixed solution I, and 7 kg of white sugar, and stir well to obtain mixed solution II.

[0043] 4) Homogenization: After the mixed liquid II is subjected to first-level homogenization and second-level homogenization, wherein, the pressure of the first-level homogenization is 40MPa, and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com