Preparation method of graphene/titanium oxide composite material and application method thereof

A technology of titanium oxide and composite materials, which is applied in the production and application of graphene/titanium oxide composite materials, can solve the problems of unfavorable industrial production, cumbersome and complicated operation process, and high cost, and achieve the suppression of shuttle effect and cycle stability Good, high battery capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

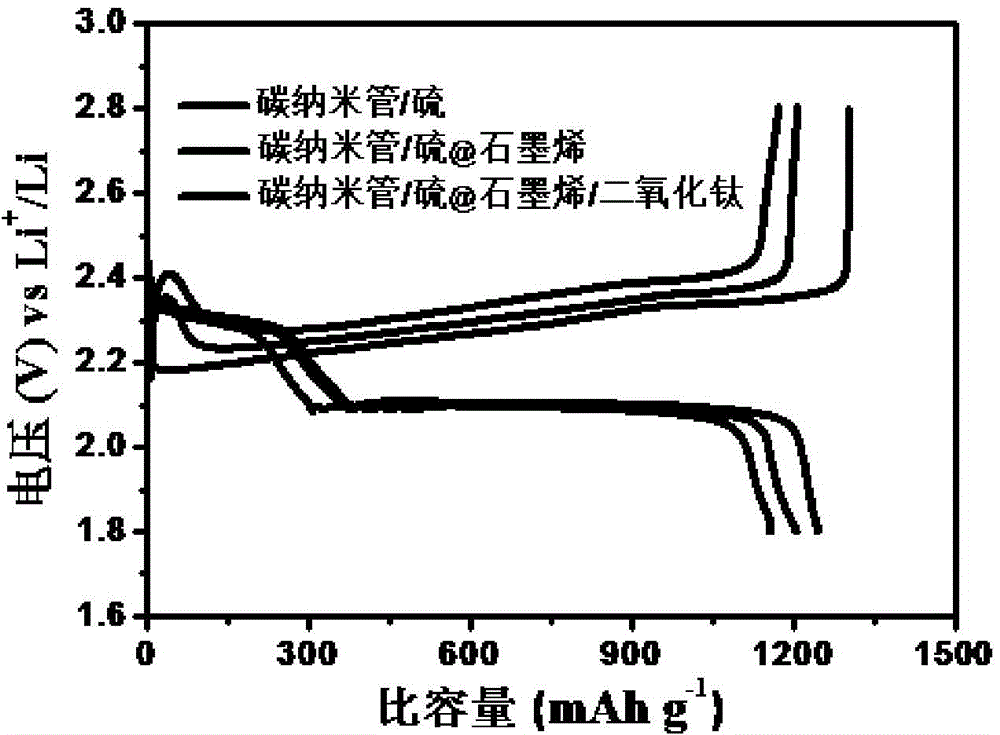

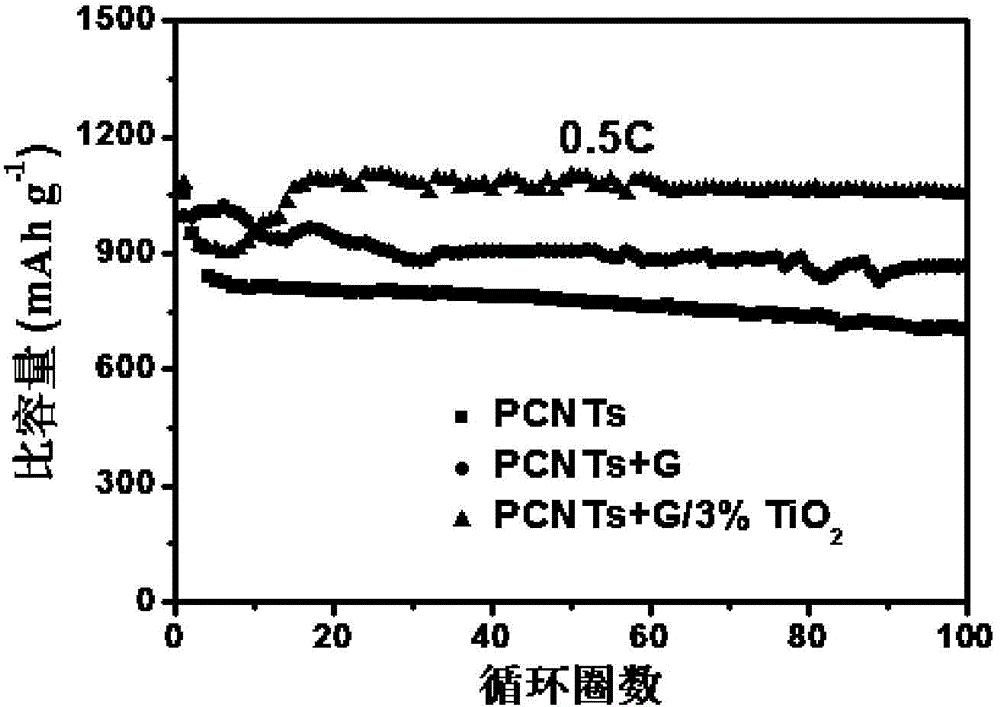

[0020] (1) According to requirements, take graphene sheets and anatase titanium dioxide with a particle size of about 5 nm according to the mass ratio of 100:3, mix and dissolve them in NMP according to the content of 1% mass ratio, stir vigorously and ultrasonically disperse, and wait The slurry reaches the proper viscosity (10-30000cP) and is ready for coating.

[0021] (2) Fully grind and mix the carbon nanotube elemental sulfur, dissolve it in carbon disulfide, stir vigorously and disperse it ultrasonically. After the carbon disulfide is volatilized, transfer the mixture to an oven, heat up to 155°C, keep the temperature for 24h, and cool to obtain carbon nanotube / sulfur The actual sulfur content of the composite cathode material is 51.2% through thermogravimetric analysis.

[0022] The composite material obtained in step (2) is uniformly mixed with acetylene black and polyvinylidene fluoride (PVDF) according to a certain amount of mass percentage (75-98): (0-15): (2-10), ...

Embodiment 2

[0026] Take graphene sheets and anatase titanium dioxide with a particle size of about 10nm at a mass ratio of 100:4, mix and dissolve them in NMP at a mass ratio of 5%, stir vigorously and ultrasonically disperse, and prepare the slurry when it reaches an appropriate viscosity coating.

[0027] Take a certain amount of commercial carbon black and elemental sulfur, grind and mix it thoroughly, dissolve it in carbon disulfide, stir vigorously and ultrasonically, until the carbon disulfide is completely volatilized, transfer the mixture to an oven, heat up to 155°C, keep the temperature for 24 hours, and cool to obtain a carbon black / sulfur composite positive electrode The material had an actual sulfur content of 52.1% as tested by thermogravimetric analysis.

[0028] The coating method and battery testing method are the same as in Example 1, and the resulting battery is charged and discharged 50 times at a current density of 0.5C. Comparing the electrode coated with graphene / t...

Embodiment 3

[0030] Take graphene sheets and anatase titanium dioxide with a particle size of about 15nm at a mass ratio of 100:5, mix and dissolve them in NMP at a mass ratio of 10%, stir vigorously and ultrasonically disperse, and prepare the slurry when it reaches an appropriate viscosity coating.

[0031] Take a certain amount of commercial carbon fiber and elemental sulfur, grind and mix it thoroughly, dissolve it in carbon disulfide, stir vigorously and ultrasonically, until the carbon disulfide is volatilized, transfer the mixture to an oven, raise the temperature to 155 °C, keep the temperature for 24 hours, and cool to obtain a carbon fiber / sulfur composite positive electrode material. Its actual sulfur content is 51.9% as tested by thermogravimetric analysis.

[0032] The coating method and battery testing method are the same as in Example 1, and the resulting battery is charged and discharged 50 times at a current density of 0.5C. Comparing the electrode coated with graphene / ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com