Method for preparing carbon fibre cloth loaded sulphur composite material

A technology of carbon fiber cloth and composite materials, which is applied in the field of preparation of carbon fiber cloth-loaded sulfur composite materials, which can solve problems affecting battery performance and positive electrode internal structure damage, and achieve stable cycle performance, improved electrochemical performance, and reduced process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

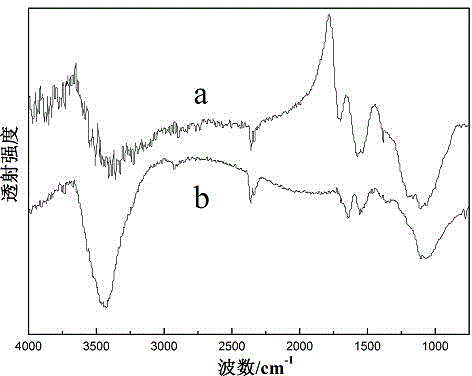

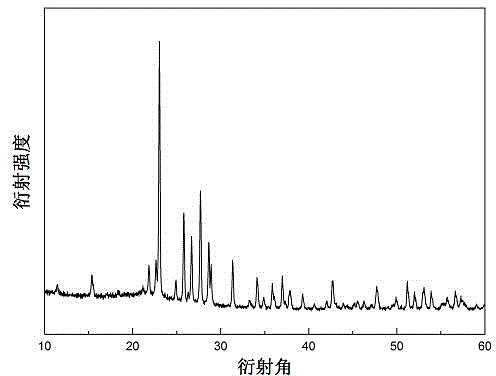

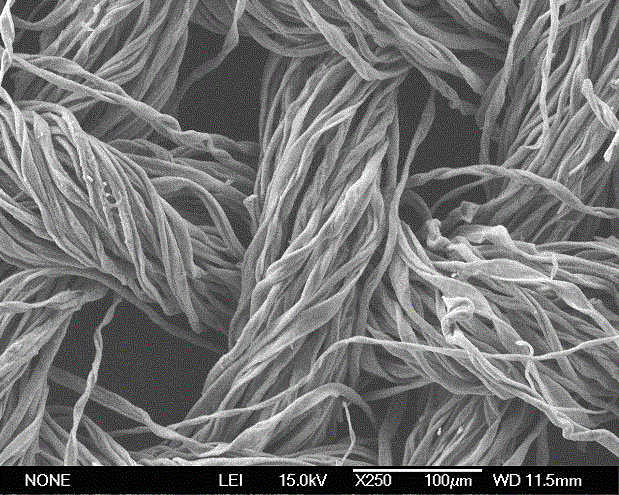

Image

Examples

Embodiment 1

[0027] Preparation of Carbon Fiber Cloth Loaded Sulfur Composite

[0028] The steps of preparation method are as follows:

[0029] 1) Functionalization of carbon fiber cloth: Take 2×2cm cotton fiber cloth, soak it in sodium hydroxide solution in a water bath at 80°C for 5h, dry it, place it in a tube furnace, and heat it at 200°C for 3h in an argon atmosphere, then raise the temperature After heat treatment at 850°C for 2 hours, a carbonized fiber cloth was obtained; the fibers were placed in concentrated nitric acid and boiled for 8 hours under reflux to obtain a functionalized conductive carbon fiber cloth;

[0030] 2) Loading nano-sulfur particles by hydrothermal method: put the carbon fiber cloth in step (a) in the prepared deionized water / ethanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:7, and move into In a 100mL reactor, a composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained...

Embodiment 2

[0035] 1) Functionalization of carbon fiber cloth: take 2×2cm cotton fiber cloth, soak it in sodium hydroxide solution in a water bath at 80°C for 10 hours, dry it and place it in a tube furnace, heat-treat it at 200°C for 10 hours in an argon atmosphere, and then heat it up After heat treatment at 1000°C for 2 hours, a carbonized fiber cloth was obtained; the fibers were placed in perchloric acid and boiled for 2 hours under reflux to obtain a functionalized conductive carbon fiber cloth;

[0036]2) Loading nano-sulfur particles by hydrothermal method: put the carbon fiber cloth in step (a) in the prepared ethanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:5, and move it into a 100mL reaction kettle , after hydrothermal reaction at 100℃ for 48h, the composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained.

Embodiment 3

[0038] 1) Functionalization of carbon fiber cloth: Take a 2×2cm cotton fiber cloth, soak it in potassium hydroxide solution in a water bath at 80°C for 5 hours, dry it and place it in a tube furnace, heat-treat it at 300°C for 1 hour in a nitrogen atmosphere, and then heat it up to Carbonized fiber cloth was obtained after heat treatment at 750°C for 2 hours; the fibers were placed in concentrated sulfuric acid and refluxed and boiled for 10 hours to obtain functionalized conductive carbon fiber cloth;

[0039] 2) Loading of nano-sulfur particles by hydrothermal method: place the carbon fiber cloth in step (a) in the prepared water / isopropanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:1, and move into In a 100mL reactor, after hydrothermal reaction at 150°C for 24h, a composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com