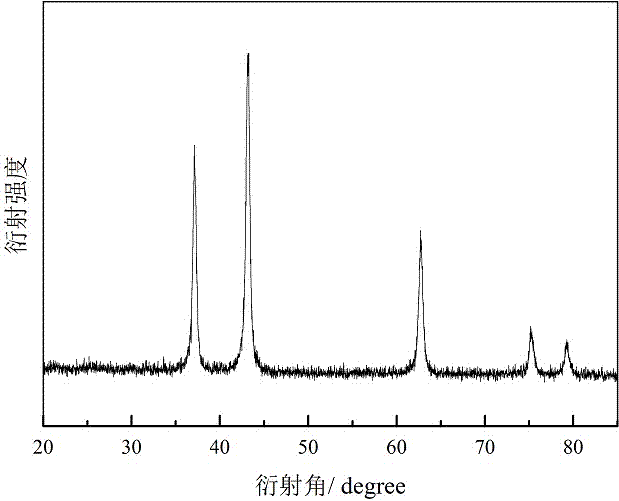

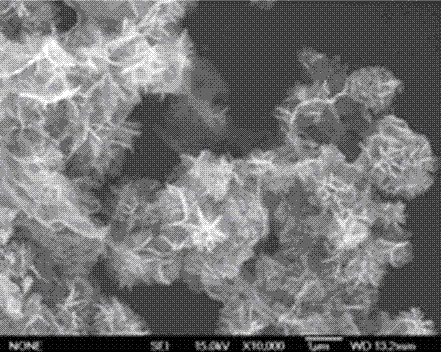

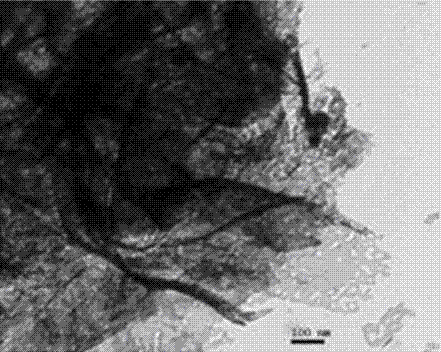

Preparation method for graphene load flower-shaped porous nickel oxide composite materials

A composite material and graphene technology, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of easy agglomeration of nickel oxide materials, long charging time, low power density, etc., achieve short preparation cycle, improve capacitance performance, overcome The effect of poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Use the traditional method of knowing the process method to prepare graphene

[0030] Potin sulfate (K 2 S 2 O 8 ) 2.5 g, five phosphorus dioxide (P (P (P (P (P (P 2 O 5 ) 2.5 g, dissolved in 12 mL concentrated sulfuric acid, and heated to 80 ° C; then add 3 G natural graphite to the above solution, heat preservation 80 ° C, 4.5 hours; cool to room temperature, dilute with 500 ml of ionic water, let it stand overnight, and stay overnight to stay overnight.; Filter, remove the residual acid with 0.2 mm filter; dry in the vacuum drying box of 60 ° C; add the obtained pre -oxides into the concentrated sulfuric acid of 120 ml ice bath, slowly add 15 g kmno under stirring 4 The temperature is kept below 20 ° C.Then the temperature is controlled at 35 ° C for 2 h.Add 250 ml to dilute the ionic water. During the dilution process, the temperature should be lower than 50 ° C during the ice bath.Stir for 2 h, add 0.7 L to ion water, and immediately add 20 ml30%H 2 O 2 , The mixtur...

Embodiment 2

[0041] The preparation of graphene is the same as the above embodiment 1.

[0042] 1) Add 10 ml of glycerin and 70 ml of de -ion water to the cup, stir to make it a average solution, and then add 40 mg of graphene to the solution, ultrasonic 10 h.

[0043] 2) Add 0.5 G NICL after the graphene is basically dissolved 2 · 6H 2 O, 1.8 g of urea and sodium 0.5 g of dulate, and stir 0.5 h.Turn the above solution into the reactor.Put the reaction kettle in the Maval furnace, heat up to 120 ° C, and keep the constant temperature for 48 hours.

[0044] 3) After the reaction kettle is cooled, turn the solution in the reactor into the cup, and then centimize the previous drive solution at 8000 RPM for 5 minutes., Dry 12h at 80 ° C, get a dry front drive sample.

[0045] 4) Then put the front -drive sample in the quartz boat, transfer it to the pipe furnace, pass the speed of 40 ml / min to remove the air in the tube, and then heat the temperature at 5 ° C / min to 500 ° C to heat up 12 hEssenceW...

Embodiment 3

[0049] The preparation of graphene is the same as the above embodiment 1.

[0050] 1) Add 40 ml of glycerin and 40 ml of exfoliating water to the bottle, stir to make it a average solution, and then add 60 mg of graphene to the solution and 4 h in ultrasound.

[0051] 2) Add 1 g Niso after graphene is basically dissolved 4 · 6H 2 O, 5.4 g carbonate and 0.7 G polyethylene pyrirol, stir 0.5 h.Turn the above solution into the reactor.Place the reaction kettle in the Maval furnace, heat up to 200 ° C, and keep the constant temperature for 6 hours.

[0052] 3) After the reaction kettle is cooled, turn the solution in the reactor into the cup, and then centimize the previous drive solution at 6000 RPM for 10 minutes.Dry 12 h at 80 ° C to get a dry front -drive sample.

[0053] 4) Then the obtained front -drive sample is placed in the quartz boat, transferred to the pipe furnace, and passed the nitrogen at a speed of 20 ml / min to eliminate the air in the tube, and then heat the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com