Self supporting three dimension device and preparation method thereof

A self-supporting and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that micro-nano devices cannot be popularized and applied, and achieve the effects of low cost, good controllability and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

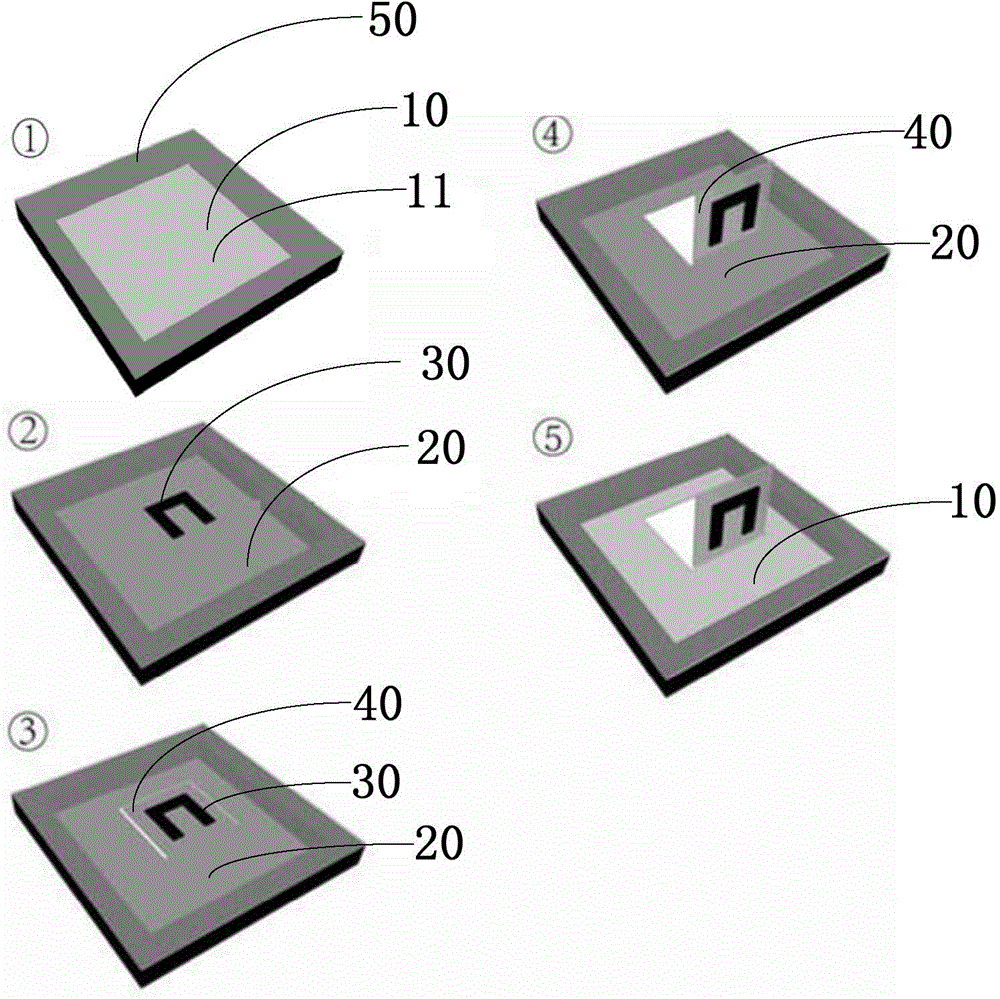

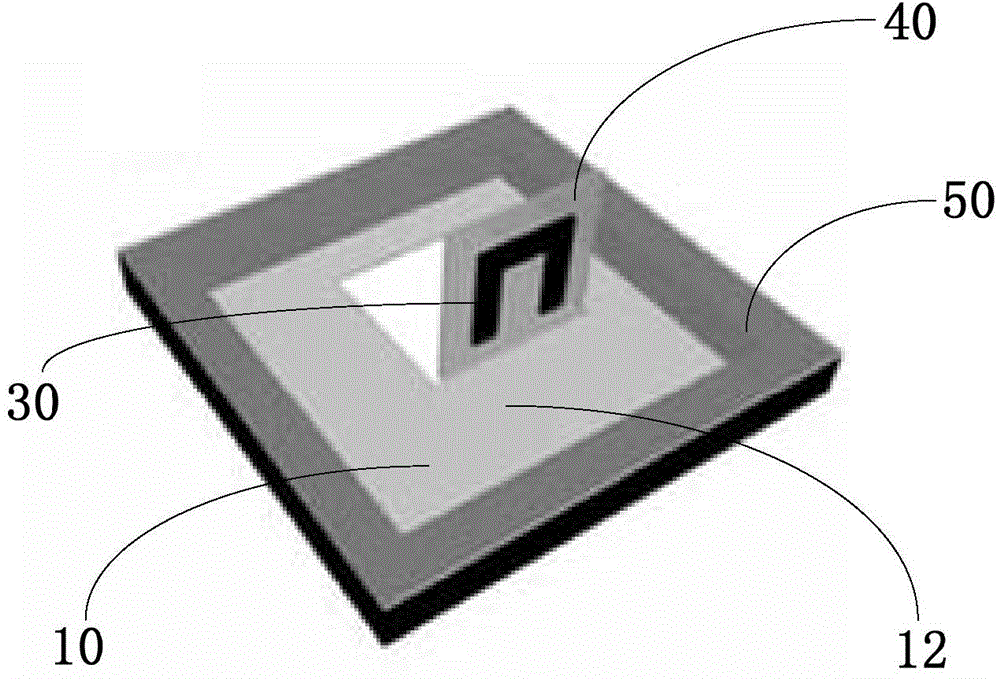

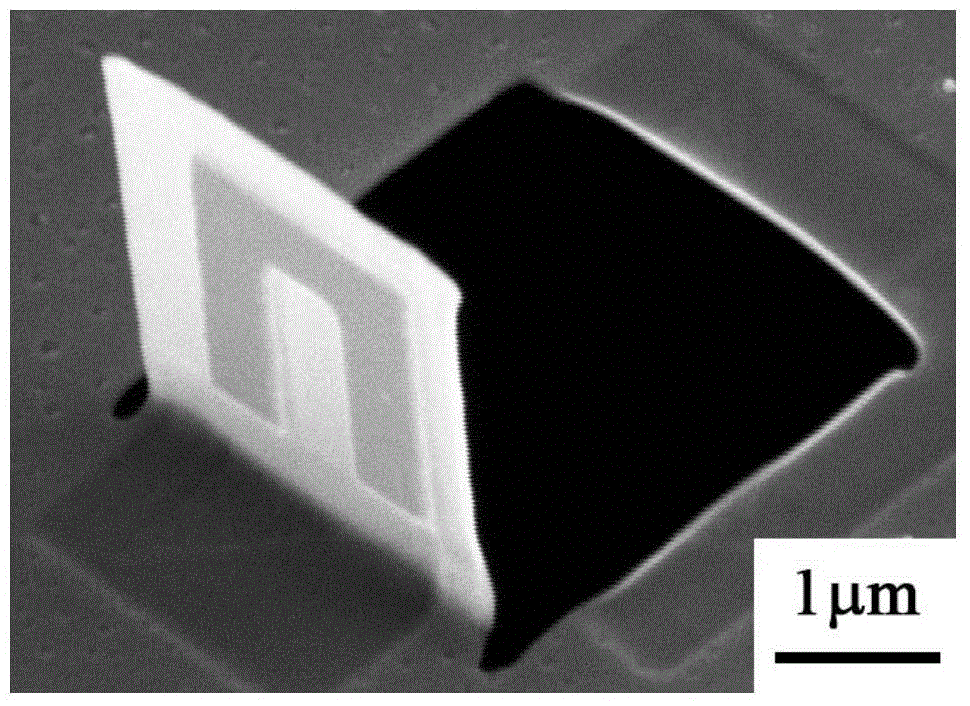

[0048] according to figure 1 The process shown in produces insulating self-supporting 3D devices with metal patterns on the surface.

[0049] Step 1: Deposit metal chromium with a thickness of 3 nm as a conductive layer on a silicon nitride window with a thickness of 50 nm (provided by Shanghai Nateng Instrument Co., Ltd.).

[0050] Step 2: Spin-coat electron beam photoresist PMMA on the conductive layer obtained in step 1 at a speed of 4000r / min, then place the silicon nitride window spin-coated with photoresist on a hot plate at 180°C for 1 minute to make it The solvent evaporates.

[0051] Step 3: Exposing and developing the sample obtained in step 2) by using an electron beam exposure process to obtain a photoresist pattern with a "U" structure with a side length of 1.7 μm and a line width of 0.5 μm.

[0052] Step 4: Evaporating a gold layer with a thickness of 50 nm on the sample obtained in step 3) by using an electron beam evaporation process.

[0053] Step 5: Soak t...

Embodiment 2

[0058] Step 1: Spin-coat a layer of UV photoresist S1813 on a self-supporting silicon oxide film (provided by Shanghai Nateng Instrument Co., Ltd.) with a thickness of 100nm, and the rotating speed during spin coating is 4000r / min. The self-supporting silicon oxide film of S1813 was baked on a hot plate at 115°C for 2 minutes to evaporate the solvent.

[0059] Step 2: Exposing and developing the sample obtained in Step 1 by using an ultraviolet exposure process to obtain an isosceles right triangle photoresist pattern with a hypotenuse length of 4 μm.

[0060] Step 3: Evaporate a silver film with a thickness of 50 nm on the sample obtained in step 2 by using an electron beam evaporation process.

[0061] Step 4: Soak the sample obtained in step 3 in acetone for 1 hour, gently blow off the silver film on the surface of the sample with a straw, remove the sample and dry it with nitrogen to obtain a metal pattern on the self-supporting silicon oxide film.

[0062] Step 5: On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com