Aramid insulation paper and preparation method thereof

A technology of insulating paper and aramid fiber, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve problems such as unsatisfactory demand, undeveloped performance products, and poor performance, so as to improve the use effect and service life, expand The effect of the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

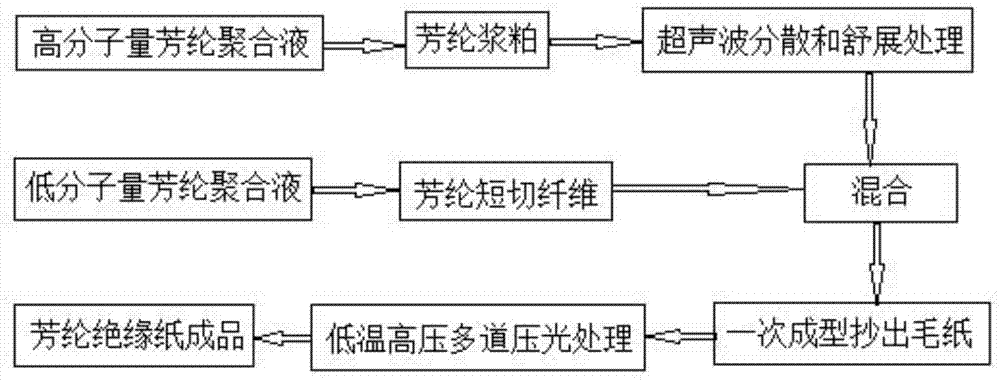

[0019] see figure 1 As shown, the preparation method of the aramid insulating paper of the present invention comprises the following steps: using a low molecular weight aramid polymer solution with a polymerization degree of 1-100 to produce aramid chopped fibers, and using a polymerization degree of 10 4 -10 6 The high molecular weight aramid fiber polymerization solution is used to produce aramid pulp, and the aramid chopped fiber and aramid pulp are respectively dispersed and disentangled by an ultrasonic disperser, and the specific surface area of the aramid pulp is set to 1.1 times the specific surface area of the above-mentioned aramid chopped fiber, the controllability of the specific surface area of the raw material is realized; the aramid pulp processed by the ultrasonic disperser is mixed with the aramid chopped fiber to form a mixed solution; The mixed li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com