A metamaterial-based waveguide photomemristor

A technology of memristor and waveguide, which is applied in the field of waveguide memristor, can solve the problems of not being able to obtain memristor, and achieve the effect of rich functionality and functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

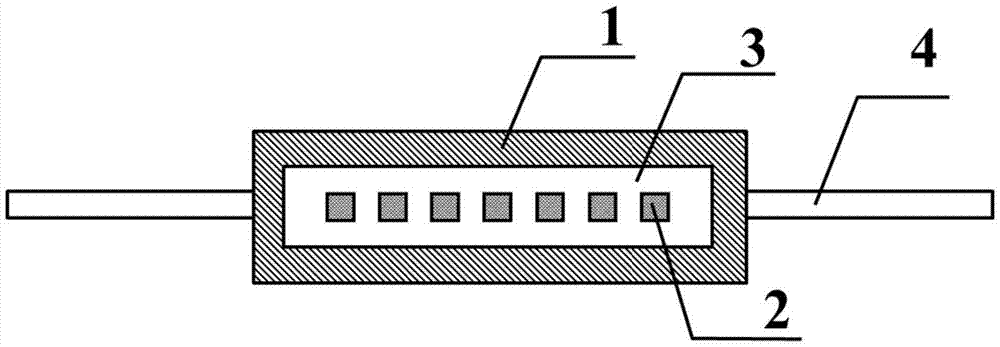

[0033] The structure of the photomemristor obtained in this embodiment is as follows figure 1 As shown, it consists of 7 optical memristors 2, 1 waveguide 1, transmission line 4 and filling medium 3;

[0034] Among them, the seven memristors 2 are all located in the waveguide 1, and are arranged in a matrix arrangement in the waveguide, and the distance between two adjacent memristors is the same; the remaining space in the waveguide 1 is filled with the filling medium 3;

[0035] The transmission line 4 is located outside the waveguide 1, and is respectively connected to both ends of the waveguide 1 by spot welding;

[0036] The material constituting the photomemristor is calcium titanate particles with a particle size of 1 μm-2 μm, a dielectric constant of 110, and a dielectric loss tangent of 0.002;

[0037] The material constituting the filling medium is polytetrafluoroethylene, a material transparent to the frequency band used by the photomemristor;

[0038] Each photom...

Embodiment 2

[0040] The optical memristor obtained in this embodiment is composed of an optical memristor, a waveguide 1, a transmission line and a filling medium;

[0041] Wherein, the optical memristor is located in the waveguide; the remaining space in the waveguide is filled with a filling medium;

[0042] The transmission line is located outside the waveguide and connected to both ends of the waveguide by spot welding;

[0043] The photomemristor is a copper ring body with a notch on the copper ring; the side length of the copper ring is 4mm, the width is 0.5mm, and the notch is 0.3mm. The gap part is equivalent to the capacitance C, and the other metal parts are equivalent to the inductance L;

[0044] The material constituting the filling medium is polytetrafluoroethylene which is transparent to the operating frequency band of the photomemristor.

Embodiment 3

[0046] The performance of the photomemristor obtained in Examples 1 and 2 can be checked using a vector network analyzer. The vector network analyzer has the functions of power scanning, time scanning and linear frequency scanning, and can well detect the performance of the prepared photomemristor. .

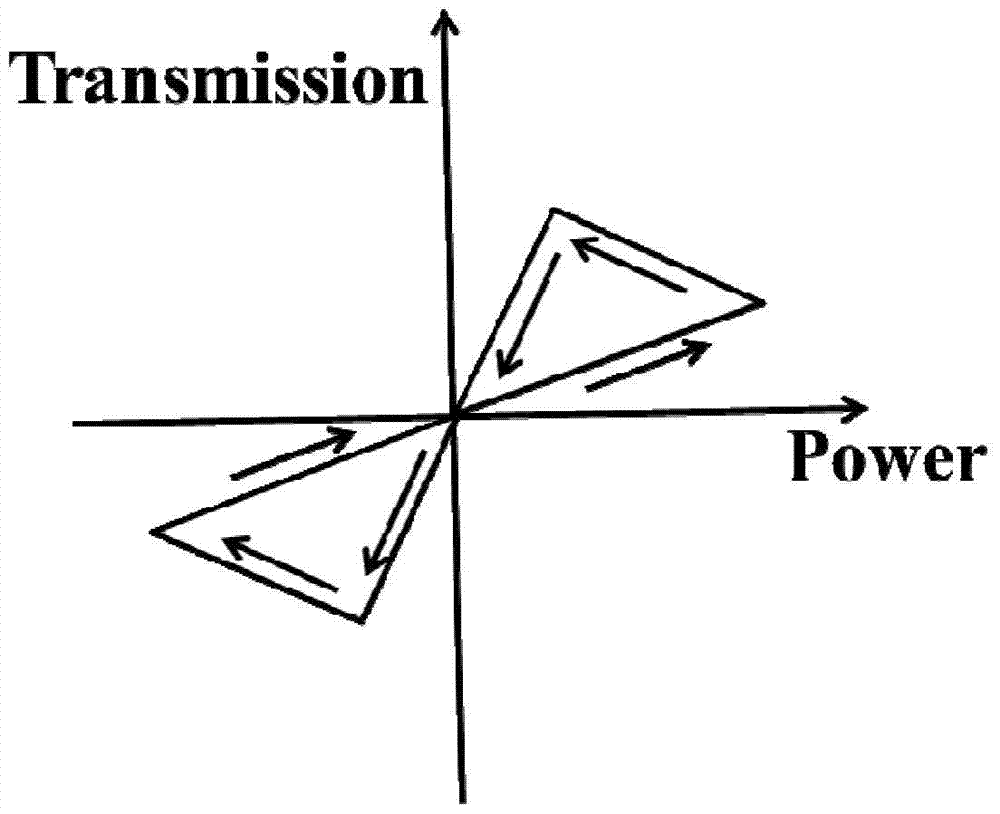

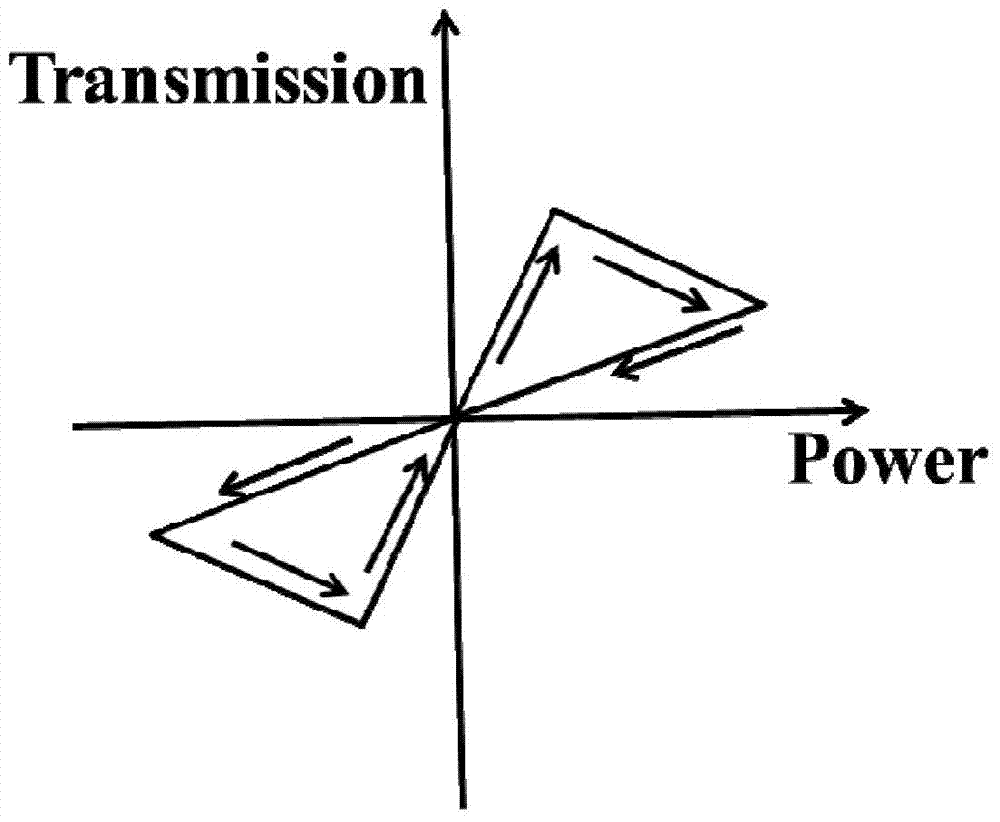

[0047] Wherein, the photomemristors obtained in Examples 1 and 2 all have the shape of figure 2 , image 3 , Figure 4 and Figure 5 the response to.

[0048] figure 2 The initial state of the memristor is a state of low transmittance, and it undergoes a transition from low transmittance to high transmittance during the process of increasing the incident power, and maintains this state of transmittance until a certain reverse power is applied. High transmittance to low transmittance reset.

[0049] and figure 2 on the contrary, image 3 A schematic diagram of the photomemristor response results in a state of high initial transmittance is given in .

[0050] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com