Intelligent remote-transmitting heat meter and working method thereof based on temperature difference and impeller complementary power generation technology

A technology of complementary power generation and temperature difference power generation, applied in the field of intelligent remote heat transfer heat meters, can solve problems such as insufficient measurement accuracy, design of thermoelectric power generation parts, loss of power supply, etc., and achieve the effect of reducing heat energy waste and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

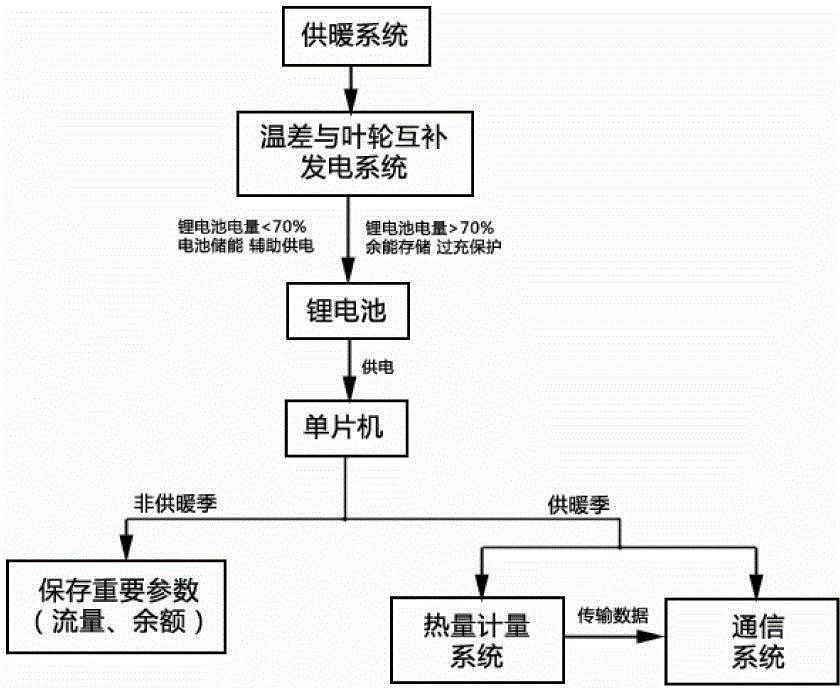

[0033] Such as figure 1 As shown, the intelligent remote heat meter based on the temperature difference and impeller complementary power generation technology in this embodiment includes four parts: power supply system, intelligent control system, heat measurement system and communication system. The power supply system mainly includes temperature difference and impeller complementary power generation system, and the heat metering system mainly includes temperature and flow rate sensors.

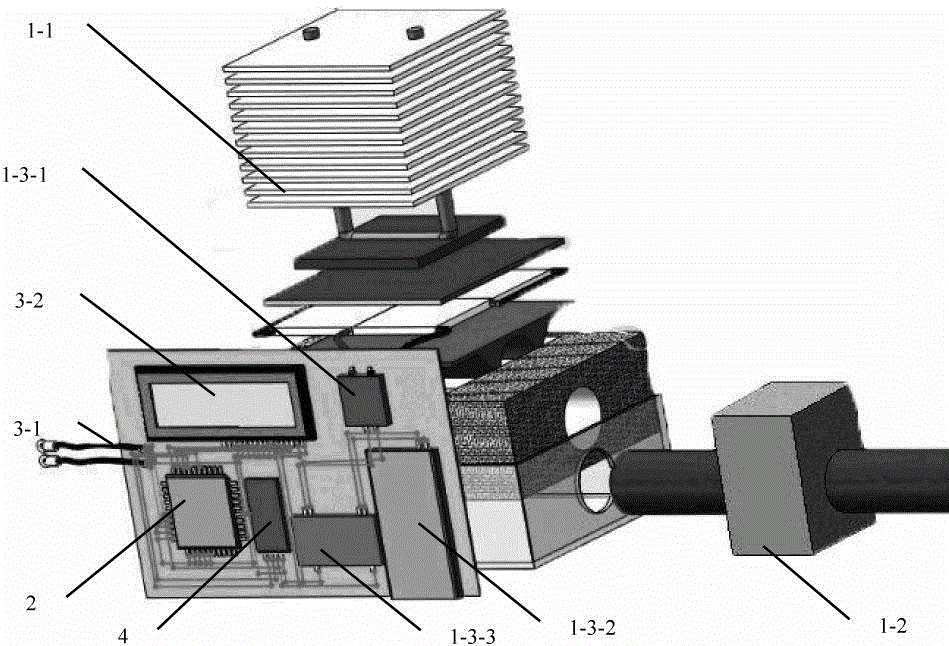

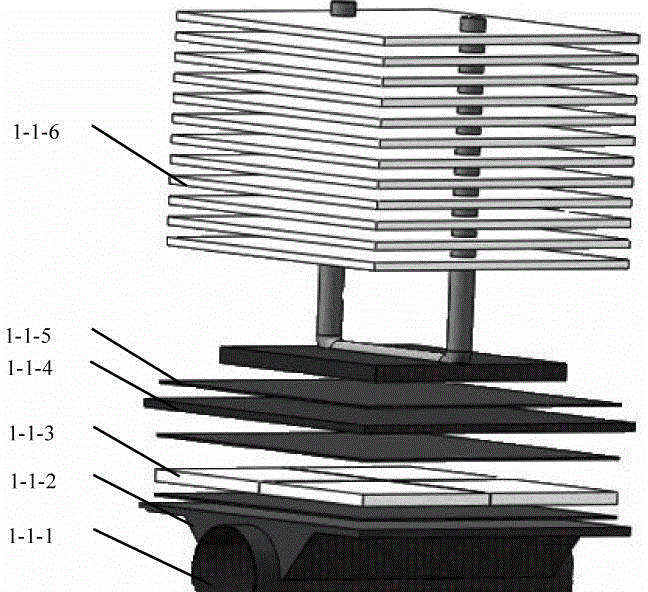

[0034] Such as figure 2 As shown, the power supply system of this embodiment is composed of a thermoelectric power generation part 1-1, an impeller power generation part 1-2 and a voltage stabilizing part. The voltage stabilizing part includes a charging and discharging module 1-3-1, a lithium ion battery 1-3-2 and a voltage boosting and stabilizing module 1-3-3. The impeller power generation part 1-2 adopts HY-368 tubular micro-flow generator, which converts the kinetic energy of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com