Smoke absorbing tank for integrated cooker

A technology of integrated stove and bellows, applied in the field of smoking boxes, can solve the problems of unreasonable structural design of smoking boxes, increased energy consumption, high power consumption, high power consumption, etc., achieve good results, reduce energy consumption, and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

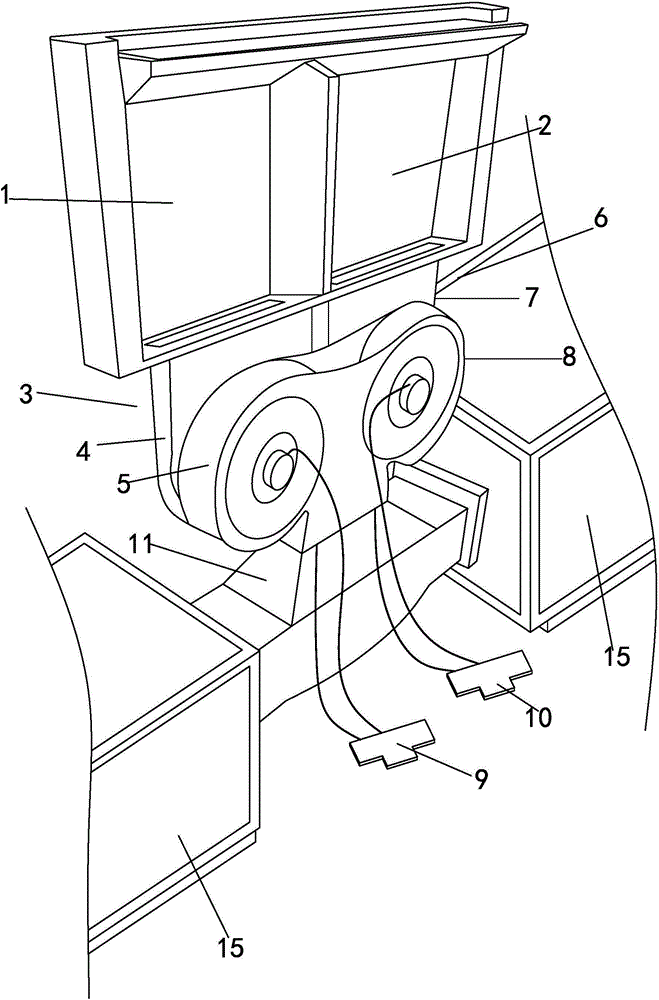

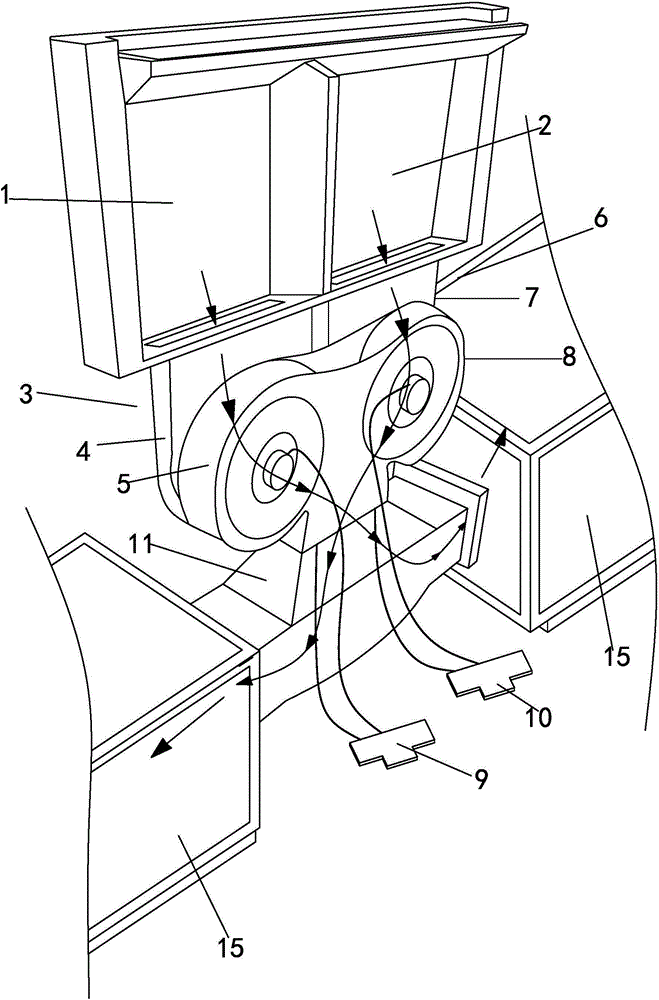

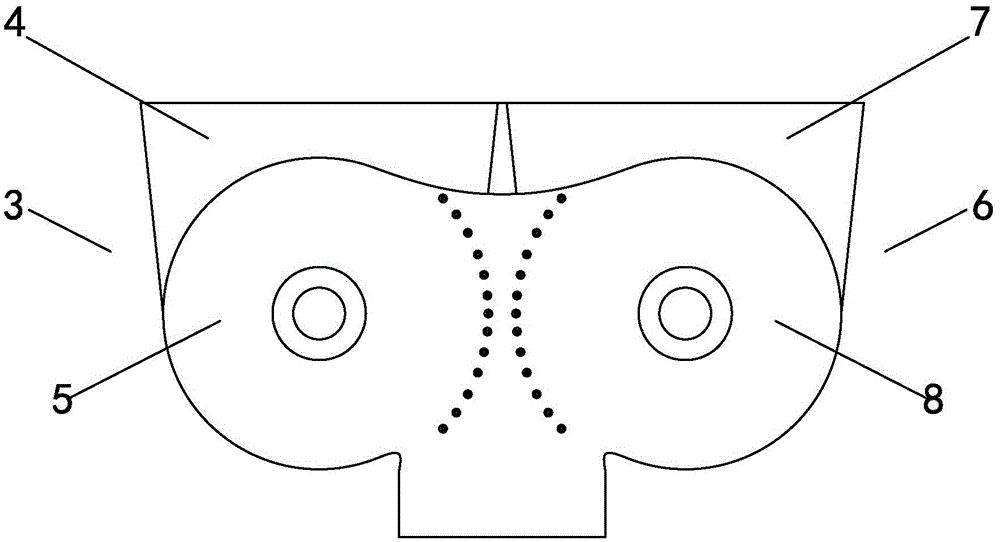

[0028] Such as Figure 1 to Figure 11As shown, a smoking box for an integrated stove includes a bellows, a drainage box, and an air outlet pipe 11. The bellows include a first bellows 1 and a second bellows 2, and the first bellows 1 and the second bellows 2 are respectively located on the left and right sides. The gas stoves on the left and right sides correspond in position. The drainage box includes a first drainage box 3 and a second drainage box 6, and the first drainage box 3 and the second drainage box 6 are respectively located on the left and right sides. The lower end of the first bellows 1 is connected to the first diversion box 3 , and the lower end of the second bellows 2 is connected to the second diversion box 6 . The first diversion box 3 includes a first diversion box 4 and a first volute 5, the first diversion box 4 is connected to the first bellows 1, the front of the first diversion box 4 is connected to the first volute 5, and the first diversion box 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com