LED (Light Emitting Diode) lamp with glass lampshade with internally-coated remote fluorescent powder and process

A technology of remote phosphor and glass lampshade, applied in the direction of lampshade, coating, light source, etc., can solve the problems of large consumption of phosphor, high mold cost, poor heat dissipation performance of lamps, etc., and achieves wide lighting range, simple design, The effect of improving the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

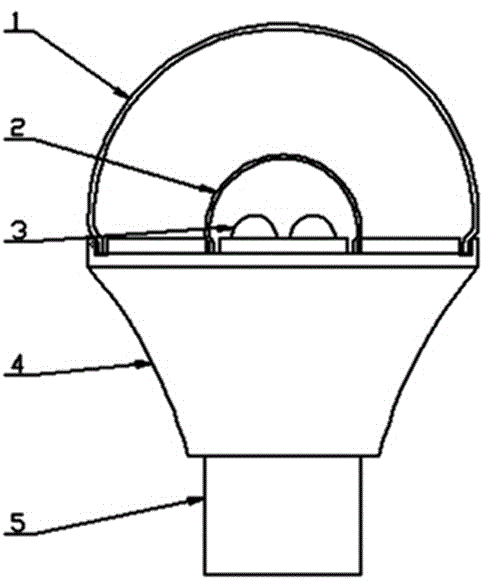

[0031] Please refer to figure 1 , an LED lamp using a glass lampshade coated with remote phosphor, which includes a lamp base 5, a radiator 4, and a light-emitting chip 3. One end of the radiator is connected to the lamp holder, and the light-emitting chip is installed on the other end of the radiator. In that: a glass lampshade 2 with phosphor powder is installed outside the luminescent chip, and the glass lampshade with phosphor powder is fixed on the other end of the radiator; in the installed state, the glass lampshade with phosphor powder is gas-tight and connects the light emitting chip and the The outside is isolated; the inner wall of the glass lampshade with fluorescent powder is coated with remote phosphor; the glass lampshade with fluorescent powder has an outer cover 1 installed in the slot at the other end of the radiator.

[0032] Certainly, in this implementation example, the outer cover may not be used at all, and the luminous performance will not be affected. ...

Embodiment 2

[0035] please see figure 2, an LED lamp using a glass lampshade coated with remote phosphor powder is basically the same as in Example 1, the difference is that: the glass lampshade with phosphor powder is semi-ellipsoidal, the upper part of the outer cover is a spherical part, and the lower part is Approximate cylindrical shape.

Embodiment 3

[0037] please see image 3 1. An LED lamp using a glass lampshade coated with remote phosphor powder is basically the same as that in Embodiment 1, except that the glass lampshade with phosphor powder is hemispherical, and the outer cover is hemispherical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com