Self-centering and anti-overturning split type return stroke plate

An anti-overturning, split-type technology, applied in liquid variable capacity machinery, variable capacity pump components, liquid fuel engines, etc., can solve problems such as the failure of the whole pump, reduce the mechanical efficiency and volumetric efficiency of the pump, etc., to achieve smooth operation, The effect of automatic neutralization is good and the mechanical efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

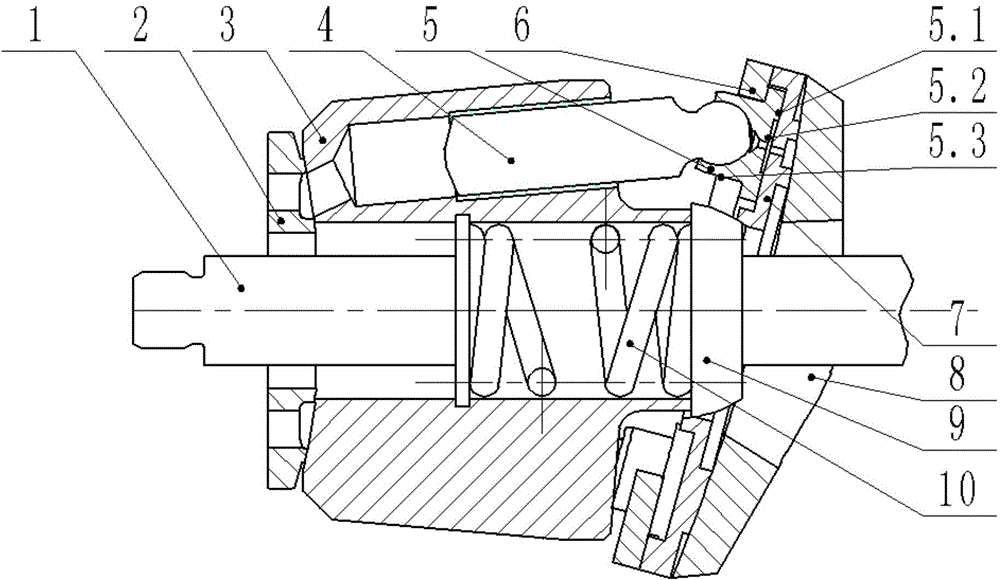

[0026] like figure 1 As shown, the present invention is a self-centering anti-overturn split type return plate, which includes an upper plate 6 and a lower plate 7, and the upper plate 6 and the lower plate 7 are two concentric discs, which are fixedly connected.

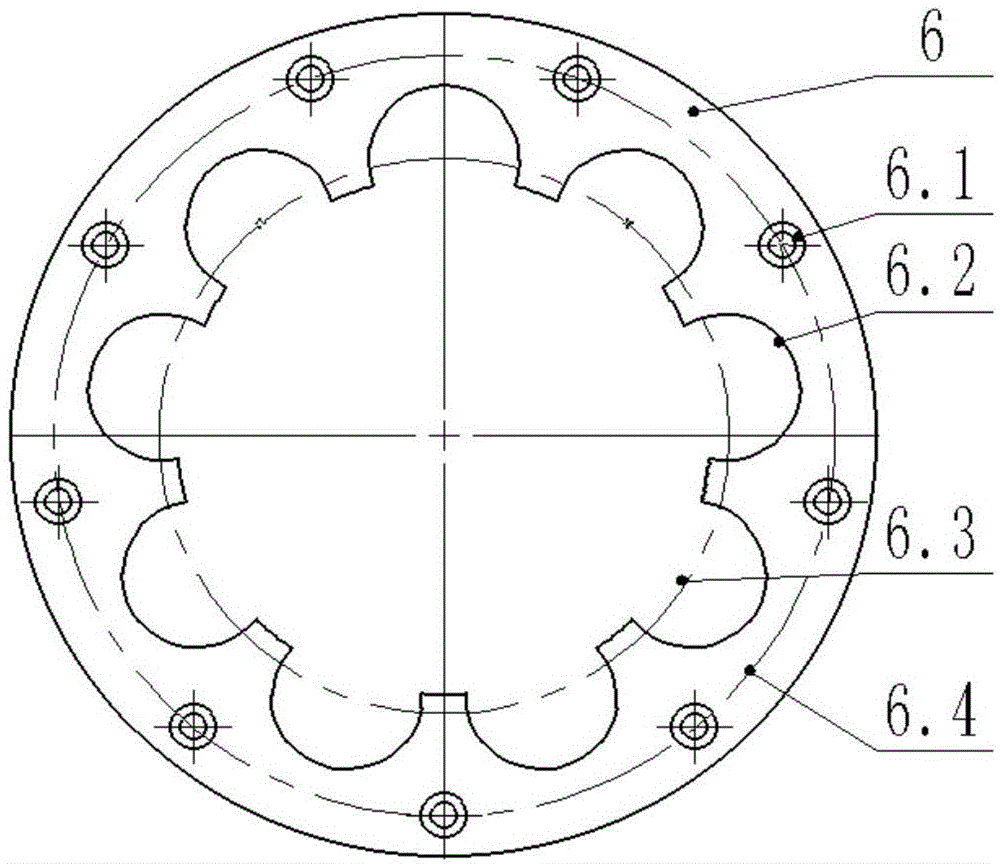

[0027] like image 3 As shown, the front end surface 7.7 of the lower wall 7 has a coaxial reinforced boss 7.8, and the lower wall 7 has a spherical hinge support hole 7.9 along the central axis, the inner hole wall of which penetrates the reinforced boss 7.8 and is a spherical arc surface; The front end surface 7.7 of the lower plate 7 has a coaxial shoe support surface limit boss 7.6, and the inner side of the shoe support surface limit boss 7.6 is connected by nine inferior arcs around the center axis of the spherical hinge support hole. Sliding shoe hole 7.2 of the lower plate; the spherical center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com