Method for producing biogas by mixing and fermenting attapulgite, crop straw and excrement

A technology for crop straw and attapulgite is applied in the fields of resources and environment, which can solve the problems of low efficiency of biogas production per unit, low added value of utilization, etc., and achieve the effects of increasing biogas production and methane content, convenient management and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

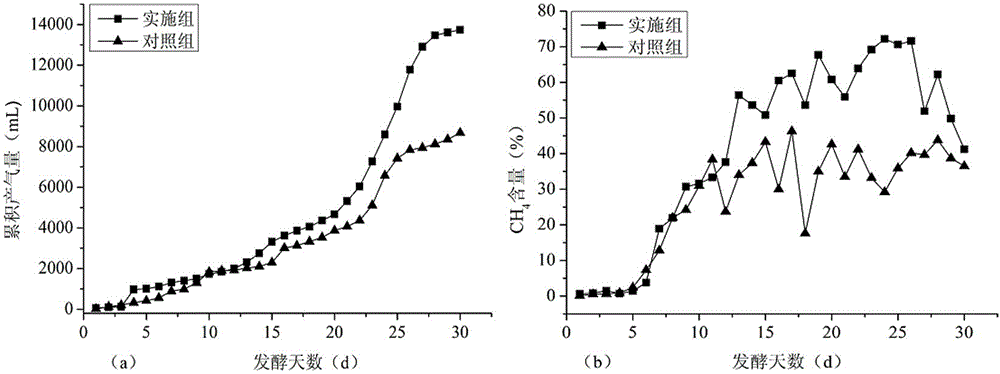

Embodiment 1

[0031] Embodiment 1: produce biogas according to the following steps

[0032] (1) Rice straw crushing: the harvested rice straw is manually cut into small pieces of 3 to 5 cm;

[0033] (2) Weigh 94.6g (dry weight 80g) of the rice straw obtained in step (1) and put it into a 2L fermenter, adjust its water content to 20% with deionized water, then immerse it in 4% NaOH solution, mix well , sealed and placed in a 25°C constant temperature biochemical incubator to react for 5 days;

[0034] (3) Add attapulgite 93.3g (dry weight 80g) and cow dung 136.3g (dry weight 80g) to the pretreated crop straw obtained in step (2), and mix evenly. At this time, the initial carbon-nitrogen ratio of the mixed material is about 20:1;

[0035] (4) Inoculate 135g of biogas slurry from an old biogas digester with a water content of 92.8% into the fermenter. At this time, the amount of the inoculum added is 10% of the dry weight of the mixed material; pH adjusted to 6.5;

[0036] (5) Seal the...

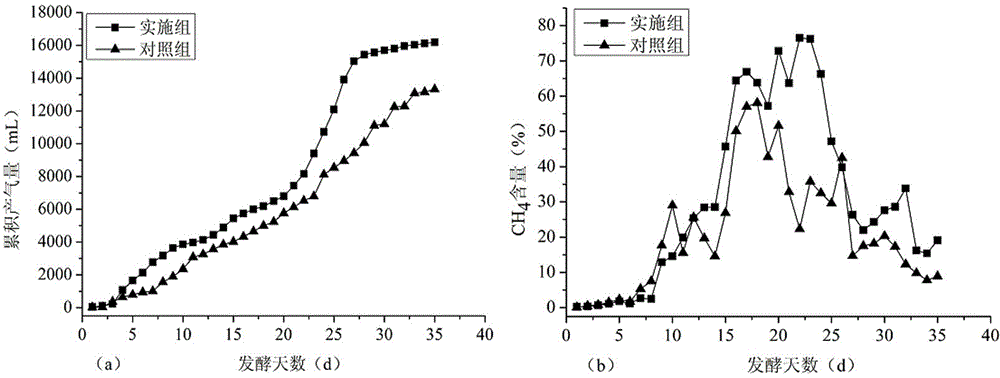

Embodiment 2

[0039] Embodiment 2: produce biogas according to the following steps

[0040] (1) Wheat straw crushing: the harvested wheat straw is mechanically cut into small pieces of 3 to 5 cm;

[0041] (2) Weigh 100.7g (dry weight 80g) of the wheat straw obtained in step (1) and put it into a 2L fermenter, adjust its water content to 25% with deionized water, then immerse it in 5% NaOH solution, mix well , sealed and placed in a 25°C constant temperature biochemical incubator to react for 6 days;

[0042] (3) Add attapulgite 81.7g (dry weight 70g) and pig manure 119.3g (dry weight 70g) to the pretreated crop straw obtained in step (2), and mix evenly. At this time, the initial carbon-nitrogen ratio of the mixed material is about 25:1;

[0043] (4) Inoculate 198g of anaerobic digested sludge from an urban sewage treatment plant with a moisture content of 95.2% into the fermenter. At this time, the amount of the inoculum added is 15% of the dry weight of the mixed material; Adjust th...

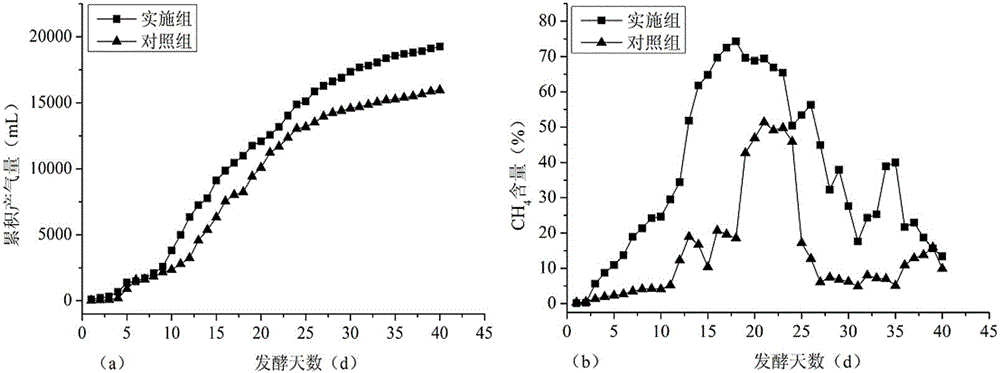

Embodiment 3

[0047] Embodiment 3: produce biogas according to the following steps

[0048] (1) Corn stalk crushing: the harvested corn stalks are crushed to 20-50 mesh through a straw kneading grinder;

[0049] (2) Weigh 102.6g (dry weight 80g) of corn stalks obtained in step (1) and put them into a 2L fermenter, adjust the water content to 30% with deionized water, then immerse in 6% NaOH solution, and mix well , sealed and placed in a 25°C constant temperature biochemical incubator to react for 7 days;

[0050] (3) Add attapulgite 70.0g (dry weight 60g) and human manure 102.2g (dry weight 60g) to the pretreated crop straw obtained in step (2), and mix evenly. At this time, the initial carbon-nitrogen ratio of the mixed material is About 30:1;

[0051] (4) Inoculate 269g of slaughterhouse sludge with a moisture content of 93.1% into the fermenter. At this time, the amount of the inoculum added is 20% of the dry weight of the mixture; add water to 2L, and then adjust the initial pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com