Hydrogenation method of coal tar

A technology for coal tar and hydro-upgrading, which is applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of great influence on catalyst activity, high impurity content of coal tar, blockage of catalyst bed, etc. The effect of improving product distribution and product properties, extending operating cycle, and suitable cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Catalyst preparation

[0053] 1. Preparation of a reverse hydrogenation catalyst I-1

[0054] Weigh 1000g of ferric oxyhydroxide filter cake prepared by wet air oxidation method, which contains 400g of ferric oxyhydroxide, add 80g of citric acid dissolved in 1L of water to it and stir to make it evenly mixed, the modification treatment time is 1h, and the treated slurry is use.

[0055] Preparation of sodium metaaluminate solution concentration is 50gAl 2 o 3 / L, a total of 1L, heated to 75°C for use, the concentration of aluminum sulfate solution is 20gAl 2 o 3 / L for a total of 2L, heated to 75°C for use.

[0056] Add 1.0L of distilled water into the gel tank and heat to 75°C. Weigh 500g (the specific surface area of macroporous alumina is 220m 2 / g, pore volume 0.92mL / g, average pore diameter 17nm) and 100g Y-type molecular sieve (SiO 2 / Al 2 o 3 =11.5), add it into the gelling tank and stir evenly, and then add sodium metaaluminate solution and aluminum ...

Embodiment 2

[0078] Catalysts I-1, I-2, I-3 and II-1 were evaluated on the activity of continuous stirring autoclaves (CSTR) in series, each reactor was loaded with 100mL of catalyst, and medium and low temperature coal tar was selected as the raw material oil for evaluation , its properties are shown in Table 2, the process conditions are shown in Table 3, and the evaluation results are shown in Table 4, Table 5 and Table 6.

[0079] Table 2 Raw Oil Properties

[0080]

[0081] Table 3 Evaluation Process Conditions

[0082]

[0083] Table 3 continued

[0084]

[0085] Table 4 gasoline fraction properties (C 5 -180°C)

[0086]

[0087] Table 4 continued

[0088]

[0089] Table 5 Properties of diesel fractions (180-350°C)

[0090]

[0091] Table 5 continued

[0092]

[0093] Table 6 Hydrogenation Tail Oil Properties (>350°C)

[0094]

[0095] Table 6 continued

[0096]

[0097] From the above evaluation results, it can be seen that after coal tar is hydrot...

Embodiment 3

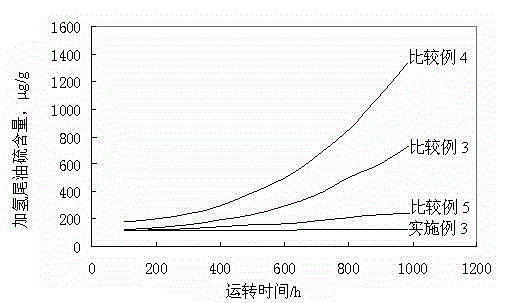

[0099] Select catalyst I-1 / II-1 in series, at a reaction temperature of 370°C, a reaction pressure of 15MPa and a space velocity of 0.5h -1 Under the condition of normal operation for 1000h, the S in the hydrogenation tail oil was sampled and analyzed at different times, and the hydrogenation activity of the catalyst at different times was obtained. figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com