Inorganic anti-cracking aging-resistant coating and preparation method thereof

An anti-aging coating, inorganic technology, applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, alkali metal silicate coatings, etc., can solve the problems of easy cracks in the film, pollute the environment, poor weather resistance, etc. Hard, easy to handle, and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

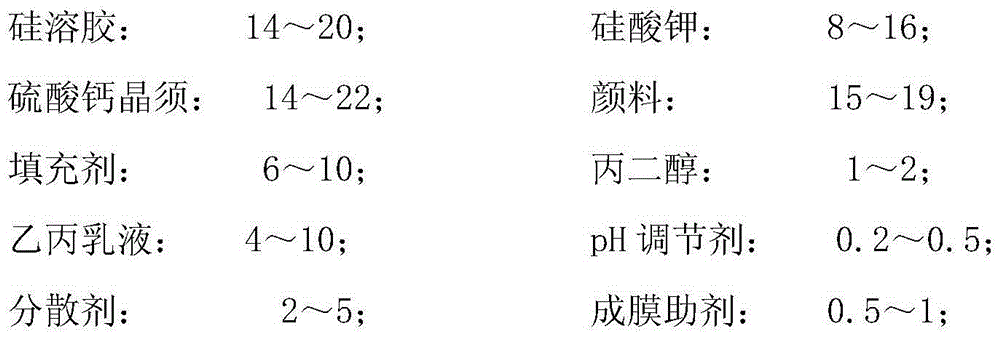

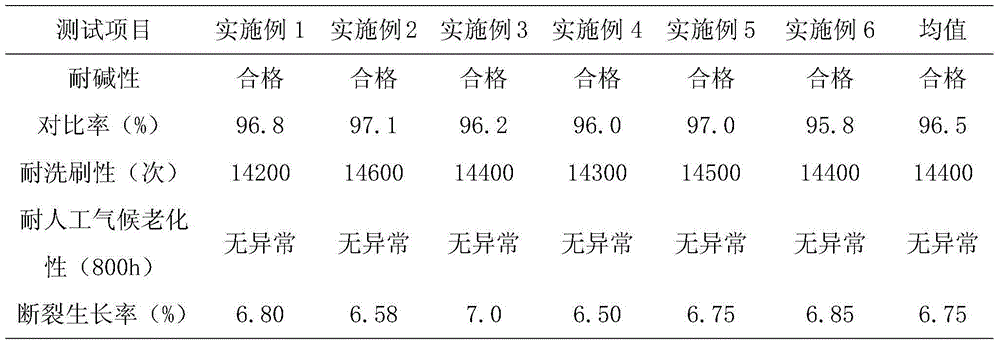

[0031] Embodiment 1: An inorganic anti-cracking and anti-aging coating, which is composed of the following raw materials in parts by weight: silica sol: 14; potassium silicate: 8; calcium sulfate whiskers: 14; titanium dioxide: 15; kaolin: 6; Ethylene-propylene emulsion: 4; propylene glycol: 1; 20% calcium hydroxide solution: 0.2; dispersant: 2; alcohol ester twelve: 0.5; Tego-810: 0.2; thickener MS-2: 0.5; water: 12 .

[0032] Calcium sulfate whiskers are prepared by the following method: Calcium sulfate dihydrate obtained after refining natural gypsum is prepared into a suspension, put into a high-pressure reactor, and under the condition of saturated vapor pressure and temperature of 110°C, calcium sulfate dihydrate transforms into It is needle-shaped calcium sulfate hemihydrate crystals, and then dried at a high temperature of 130° C. to obtain the anhydrous calcium sulfate whiskers of the present invention.

[0033] The preparation method of above-mentioned inorganic ant...

Embodiment 2

[0038] Embodiment 2: An inorganic anti-cracking and anti-aging coating, which is composed of the following raw materials in parts by weight: silica sol: 20; potassium silicate: 16; calcium sulfate whiskers: 22; titanium dioxide: 19; lithopone: 6; aluminum oxide: 4; ethylene-propylene emulsion: 10; propylene glycol: 2; 20% calcium hydroxide solution: 0.5; dispersant: 5; alcohol ester twelve: 1; Tego-810: 0.5; thickener MS- 2:1; water: 18.

[0039] Calcium sulfate whiskers are prepared by the following method: Calcium sulfate dihydrate obtained after refining natural gypsum is formulated into a suspension, put into a high-pressure reactor, and under the condition of saturated vapor pressure and temperature of 130°C, calcium sulfate dihydrate transforms into It is needle-shaped calcium sulfate hemihydrate crystals, and then dried at a high temperature of 130° C. to obtain the anhydrous calcium sulfate whiskers of the present invention.

[0040] The preparation method of above-me...

Embodiment 3

[0045] Embodiment 3: An inorganic anti-cracking and anti-aging coating, which is composed of the following raw materials in parts by weight: silica sol: 16; potassium silicate: 10; calcium sulfate whiskers: 16; titanium dioxide: 18; kaolin: 3; Lithopone: 1; Aluminum oxide: 3; Ethylene-propylene emulsion: 5; Propylene glycol: 1.4; 20% calcium hydroxide solution: 0.3; Dispersant: 3; Alcohol ester twelve: 0.6; Tego-810: 0.3; Thickener MS-2: 0.7; Water: 14; Fungicide: 0.3; Antifungal agent: 0.8.

[0046] Calcium sulfate whiskers are prepared by the following method: Calcium sulfate dihydrate obtained after refining natural gypsum is prepared into a suspension, put into a high-pressure reactor, and under the condition of saturated vapor pressure and temperature of 115°C, calcium sulfate dihydrate transforms It is needle-shaped calcium sulfate hemihydrate crystals, and then dried at a high temperature of 130° C. to obtain the anhydrous calcium sulfate whiskers of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com