A kind of anionic emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and anion, which is used in construction, building components, building insulation materials, etc., can solve problems such as cumbersome operation, achieve good stability, and expand varieties and types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of described anionic emulsified bitumen, comprises the steps:

[0060] (1) heating the asphalt to 130°C to 200°C;

[0061] (2) Diluting the auxiliary agent with water to obtain a diluted auxiliary agent;

[0062] (3) Dissolving the anionic surfactant and the diluted auxiliary agent in water at 50°C to 90°C to make a soap solution, and adjusting the pH value to 9-13;

[0063] (4) Pass the soap liquid into a high-speed shear mixing equipment, such as a high-speed shear colloid mill, circulate and heat the soap liquid to between 90°C and its boiling point;

[0064] (5) Continuously feed the soap solution, pass the asphalt into the mixing equipment from the inlet, obtain the emulsified asphalt system formed by dispersing the asphalt in water through high-speed shearing, and discharge it into the product tank from the outlet;

[0065] (6) Keep the mixing equipment and product tank pressure higher than the saturated vapor pressure of the emulsion;

[0...

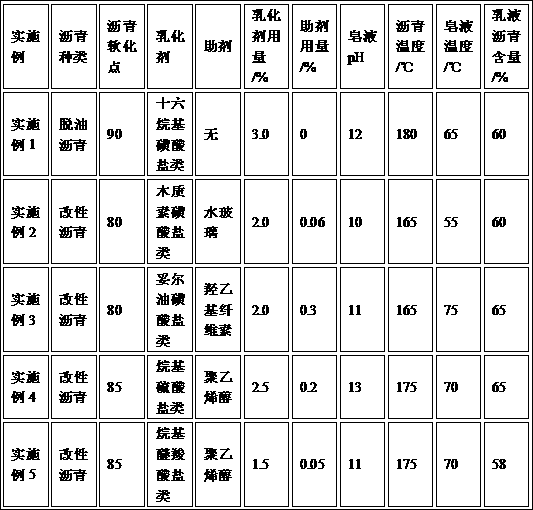

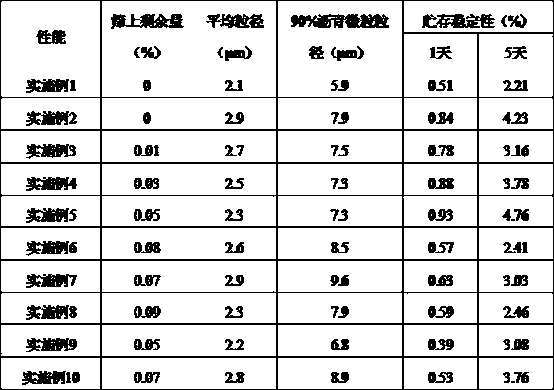

Embodiment 1-5

[0099] Example 1-5 The process conditions are as shown in Table 1. After heating the asphalt with the softening point as shown in Table 1, add the asphalt tank and raise the temperature to the temperature shown in Table 1. The anionic surfactant and the diluted auxiliary agent are dissolved in water , be mixed with soap liquid, and make soap liquid after adjusting pH value and add soap liquid tank, soap liquid pH value, heating temperature are as shown in table 1. The colloid mill is heated to near soap liquid temperature. The soap solution is passed through the high-speed shear mixing equipment at a certain flow rate from the inlet, such as a high-speed shear colloid mill, and discharged from the outlet; the soap solution is continuously fed, and the asphalt is passed into the mixing equipment at a certain flow rate from the inlet , the colloidal dispersion system formed by bitumen dispersed in water is obtained by high-speed shearing, and discharged from the outlet; pressuri...

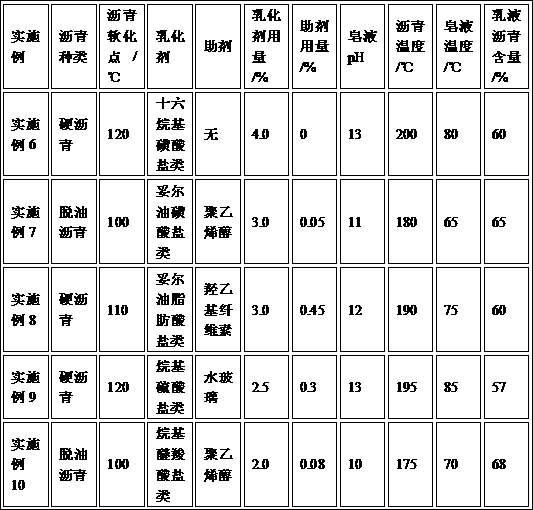

Embodiment 6-10

[0103] Example 6-10 The process conditions are as shown in Table 2. After heating the asphalt with the softening point as shown in Table 2, add the asphalt tank and raise the temperature to the temperature shown in Table 2. The anionic surfactant and the diluted auxiliary agent are dissolved in water , be mixed with soap liquid, and make soap liquid after adjusting pH value and add soap liquid tank, soap liquid pH value, heating temperature are as shown in table 2. The colloid mill is heated to near soap liquid temperature. The soap solution is passed through the high-speed shear mixing equipment at a certain flow rate from the inlet, such as a high-speed shear colloid mill, and discharged from the outlet; the soap solution is continuously fed, and the asphalt is passed into the mixing equipment at a certain flow rate from the inlet , the colloidal dispersion system formed by asphalt dispersed in water is obtained by high-speed shearing, and discharged from the outlet; the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com