Preparation method for organic amine carbaminate

An organic amine amino, formate technology, applied in the preparation of carbamate derivatives, the preparation of organic compounds, organic chemistry and other directions, can solve the problems of high energy consumption, difficulty in solvent removal, etc., achieve less dosage and improve reaction rate. And the effect of salt formation rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of organic amine carbamate, comprises the following steps:

[0026] Under normal temperature and pressure, add the organic amine and organic solvent with a mass ratio of 100:(2~500) into the closed reaction device, keep stirring at the speed of 300~2400rpm at -10℃~100℃, and add to the reaction The device is filled with CO 2 Gas, generally make the gas in the reaction device (mainly CO 2 Gas) pressure reaches 0.1MPa~15MPa, after 2min~10h of reaction, the organic amine fully reacts completely, releases the pressure, and obtains the post-reaction solution, if there is white solid in the post-reaction solution, filter the post-reaction solution, centrifuge or distill off the solvent, A white solid is obtained, and after drying, an organic amine carbamate with a purity of 90% to 98% is obtained; if there is no white solid in the solution after the reaction, the solvent is distilled off from the solution after the reaction, and the obtained mucus is an...

Embodiment 1

[0040] The preparation method of 1,6-hexanediamine carbamate:

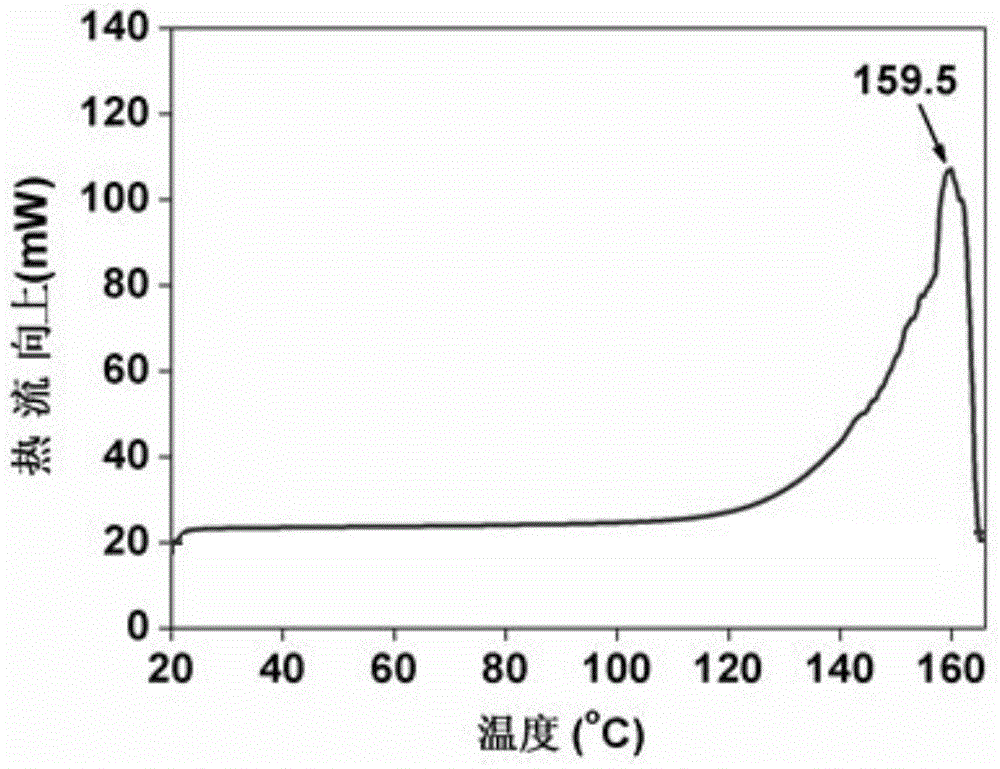

[0041] Add 10ml of industrial ethanol and 20g of 1,6-hexanediamine into the 80ml reaction kettle, seal it, put it in an oil bath at 60°C, under continuous magnetic stirring (speed 1200rpm), preheat for 5min, then pump CO2 into the reaction kettle 2 Gas, the pressure reaches 3MPa. After 2 minutes of reaction, the pressure is released to open the kettle, the solvent is distilled off, and dried to obtain a white solid of 1,6-hexamethylenediamine carbamate with a yield of 90% and a melting point of 157°C-160°C.

[0042] The hexamethylenediamine carbamate prepared in embodiment 1 is carried out infrared spectrum detection, the result is as follows figure 1 shown, from figure 1 It can be seen that 3335cm -1 It is the N-H bond stretching vibration peak of primary amino group and secondary amino group in carbamate; 2930cm -1 and 2850cm -1 Antisymmetric and symmetric stretching vibration peaks of the C-H bond of methyl...

Embodiment 2

[0046] The preparation method of 1,6-hexanediamine carbamate:

[0047] In the 800ml reactor, add 40ml ethyl acetate and 200g 1,6-hexamethylenediamine, after airtight, in an oil bath at 65°C, under continuous magnetic stirring (speed 2400rpm), preheat for 5min, then pump into the reactor CO 2 Gas, pressure up to 9MPa, react for 3min, release the pressure and open the kettle, filter to remove the solvent, and dry to obtain a white solid of 1,6-hexamethylenediamine carbamate with a yield of 92% and a melting point of 157°C-160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com