Industrial preparation method of high-purity sodium pantothenate

A high-purity sodium pantothenate technology, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as time-consuming, unsuitable for industrial production, and failure to achieve crystallization and impurity removal. Quality and yield, suitable for industrial production, and the effect of avoiding difficult dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

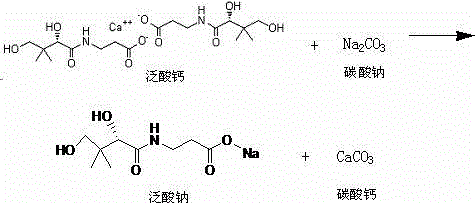

Image

Examples

Embodiment 1

[0025] Add 50 grams of calcium pantothenate into 150ml of purified water, stir to dissolve, add dropwise sodium carbonate solution (11.12 grams of sodium carbonate dissolved in 35ml of water), react for 20 minutes after the dropwise addition within 30 minutes, and then filter; add 0.5 grams of activated carbon to the filtrate , stirred for 30 minutes and then filtered through the membrane; when the membrane solution was concentrated under reduced pressure at 55°C to 75 grams of the remaining feed solution, 120 grams of absolute ethanol was added, and after stirring evenly, the feed solution was dropped into 600 grams of acetone, and then raised After crystallizing for 2 hours, filter and then vacuum-dry at 40-50°C to obtain 44 grams of sodium pantothenate dry product with a purity of 99.8%.

Embodiment 2

[0027] Add 50 grams of calcium pantothenate to 200ml of purified water, stir to dissolve, add dropwise sodium carbonate solution (11.12 grams of sodium carbonate dissolved in 35ml of water), react for 30 minutes after the dropwise addition within 30 minutes, and then filter; add 0.5 grams of activated carbon to the filtrate , stirred for 30 minutes and then filtered through the membrane; when the membrane solution was concentrated under reduced pressure at 55°C to 100 grams of the remaining feed solution, 200 grams of absolute ethanol was added, and after stirring evenly, the feed solution was dropped into 1000 grams of acetone, and then raised After crystallizing for 2 hours, filter and then vacuum-dry at 40-50°C to obtain 44.7 g of sodium pantothenate dry product with a purity of 99.7%.

Embodiment 3

[0029] Add 50 grams of calcium pantothenate to 250ml of purified water, stir to dissolve, add dropwise sodium carbonate solution (11.12 grams of sodium carbonate dissolved in 42ml of water), and react for 50 minutes after the dropwise addition within 30 minutes, then filter; add 0.5 grams of activated carbon to the filtrate , stirred for 30 minutes and then filtered through the membrane; when the membrane solution was concentrated under reduced pressure at 55°C to 115 grams of the remaining material liquid, 230 grams of absolute ethanol was added, and after stirring evenly, the material solution was dropped into 1700 grams of acetone to grow crystals Filter after 2 hours, and then vacuum-dry at 40-50°C to obtain 45 grams of sodium pantothenate dry product with a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com